Rolling barrel electroplating device

An electroplating device and drum technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems that are contrary to the development direction of relay product surface electroplating, the electric wire is easy to be twisted, damaged, and the cost of material and labor is large, so as to save material cost and Effects of maintenance cost, labor cost reduction, and plating time shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

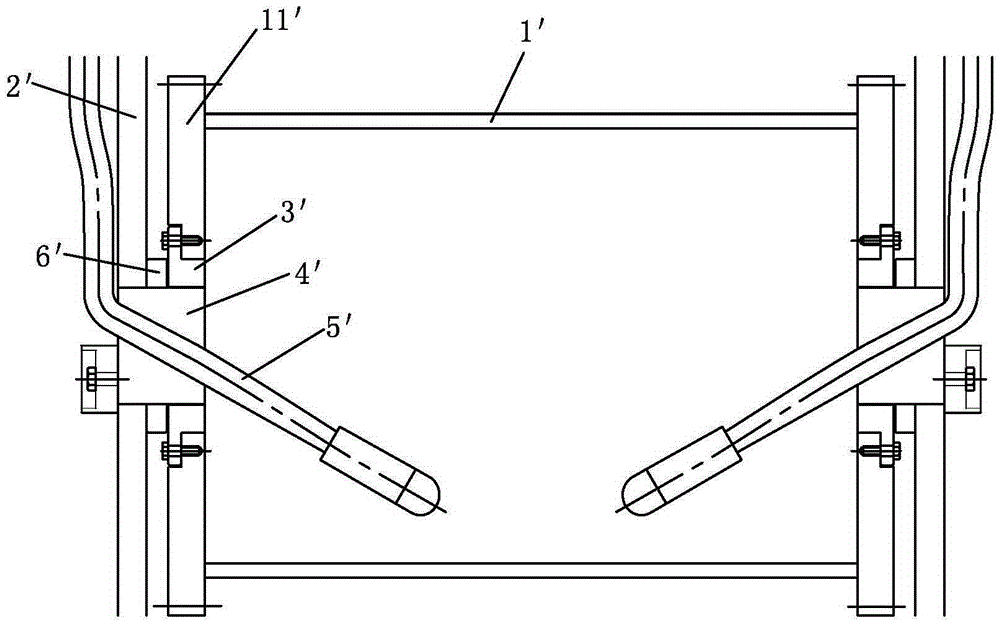

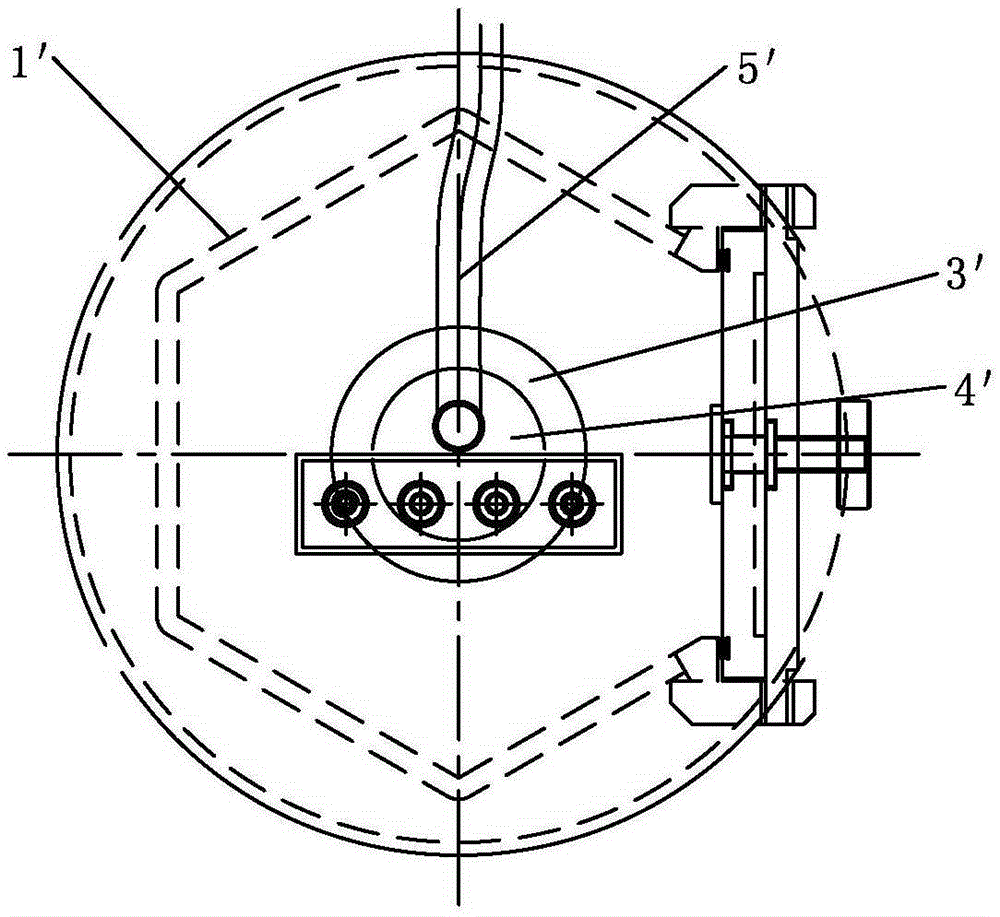

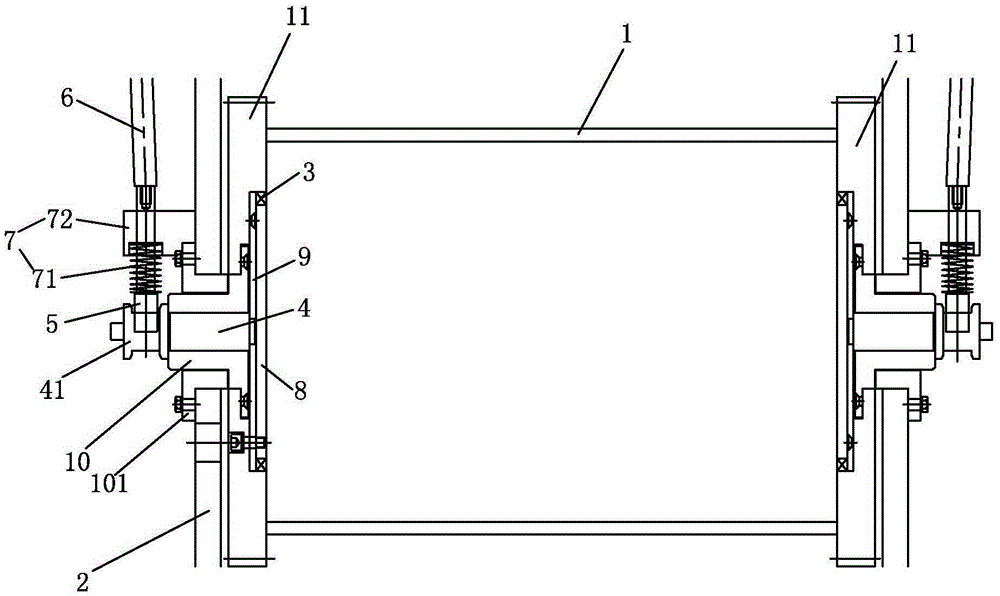

[0031] example, see Figure 3-Figure 6 As shown, a drum electroplating device of the present invention includes a bracket 2 and a drum 1. The drum 1 is a hollow structure, and the two ends of the drum 1 are respectively formed or fixedly connected to one end cover 11. The drum 1 passes through the two The end cover 11 is rotatably connected to the bracket 2 ; the side wall of the drum 1 is also mounted with a movable cover 13 for parts to enter and exit the drum 1 , and the movable cover 13 is locked by a locking mechanism 14 . The present invention also includes two conductive mechanisms that cooperate with the two end covers 11 one by one, the two conductive mechanisms respectively include a conductive bush 5 for connecting the cable 6, a planar conductive member and a conductive shaft 4; the conductive member is installed on the On the inner end surface of the end cover 11, the conductive shaft 4 is fixed on the end cover 11 and is located at the rotation axis of the end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com