Hanging ladder for maintaining electric transmission wire

A technology for transmission wires and soft ladders, which is applied in ladders, overhead lines/cable equipment, buildings, etc., and can solve problems such as increasing the work intensity of equipotential workers, failing to effectively ensure the tensile strength of wires, and increasing the gap between deformed pre-twisted wires, etc. , to improve the maintenance quality, reduce the maintenance cost and speed up the maintenance progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

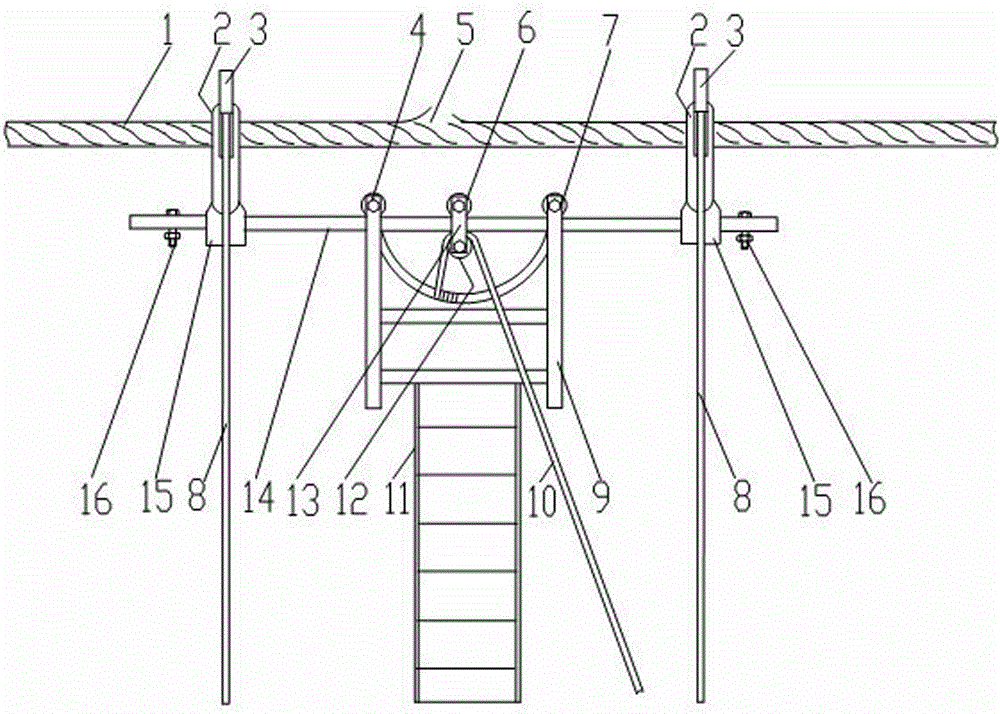

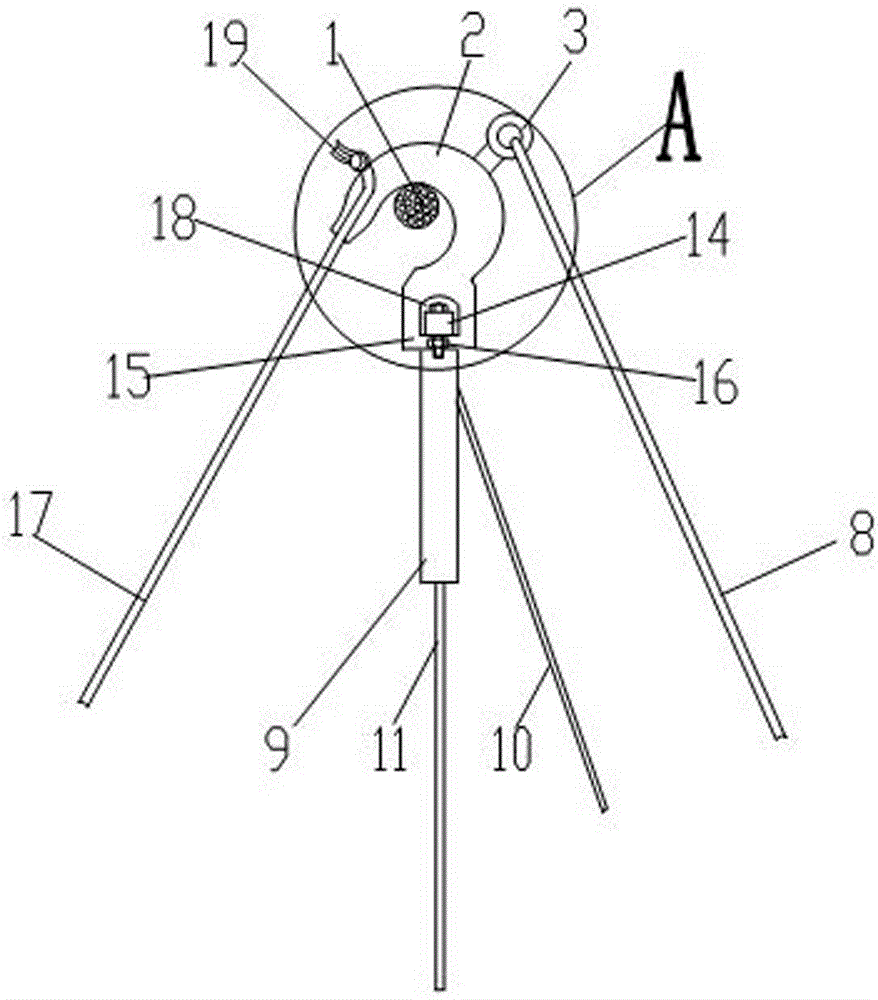

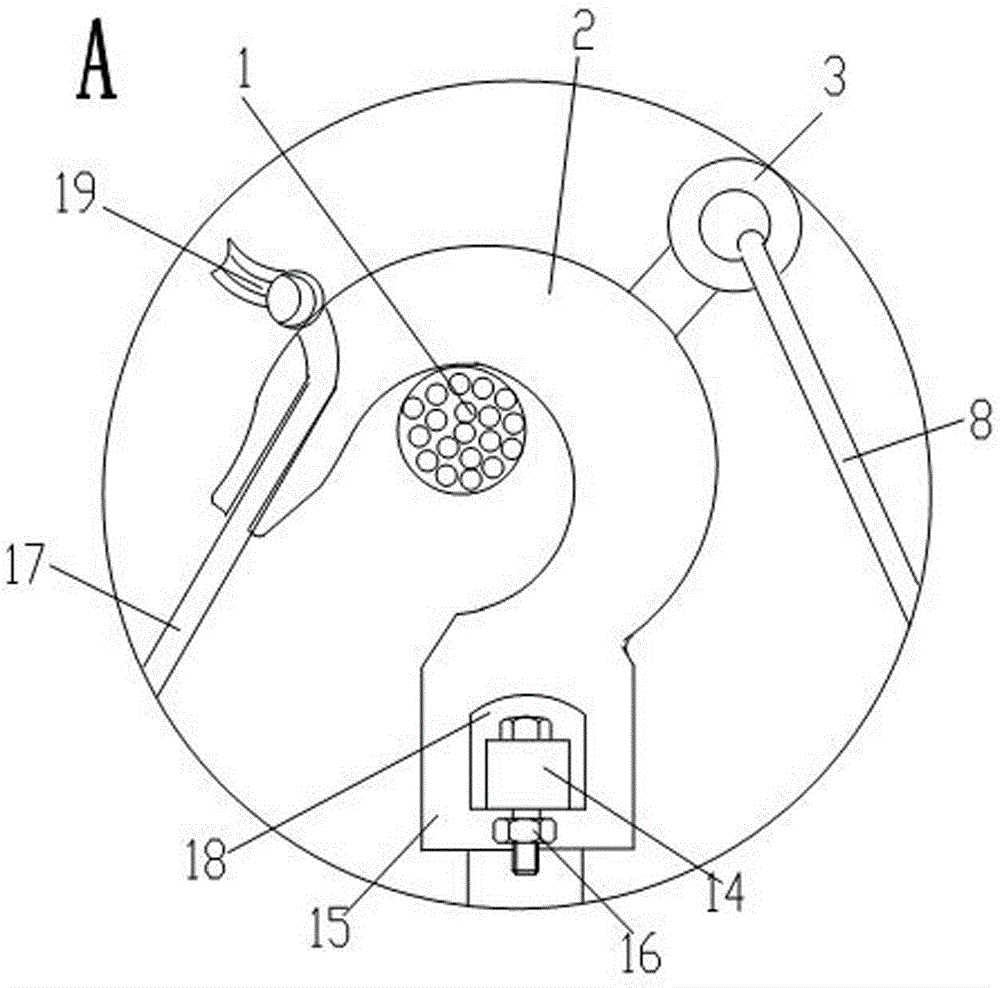

[0012] A hanging ladder for checking and repairing power transmission wires, comprising a hook 2, a hook rope 17, a hook removal rope 8, a crossbeam 14 and a sliding ladder frame 9; a pair of the hooks 2 are respectively hung on the power transmission wire 1, and each hook 2 is provided with a A hook rope 17 and a hook rope 8 are arranged, one end of the hook rope 17 is fixed with the hook 2, and the other end of the hook rope 17 is fixed along the head end of the hook 2 and extends downward, and one end of the hook rope 8 is It is fixed on the upper part of the hook 2, and the other end of the unhook rope 8 extends downward; the lower part of the hook 2 is provided with a connecting block 15, and the connecting block 15 is provided with a transverse through hole 18, and the two ends of the crossbeam 14 respectively pass through The through hole 18 is also provided with a limiting part, and the sliding ladder frame 9 is suspended on the beam 14 between the two hooks 2 . The sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com