Fully-sealed intelligent over-the-line drill pipe joint

A technology of over-the-line drilling and full sealing, applied in drill pipe, drill pipe, drilling equipment, etc., can solve the problems of affecting the sealing effect, occupying the inner diameter space of the drill pipe, and increasing the displacement, so as to improve the sealing insulation performance and realize the torque The effect of improving transmission and vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

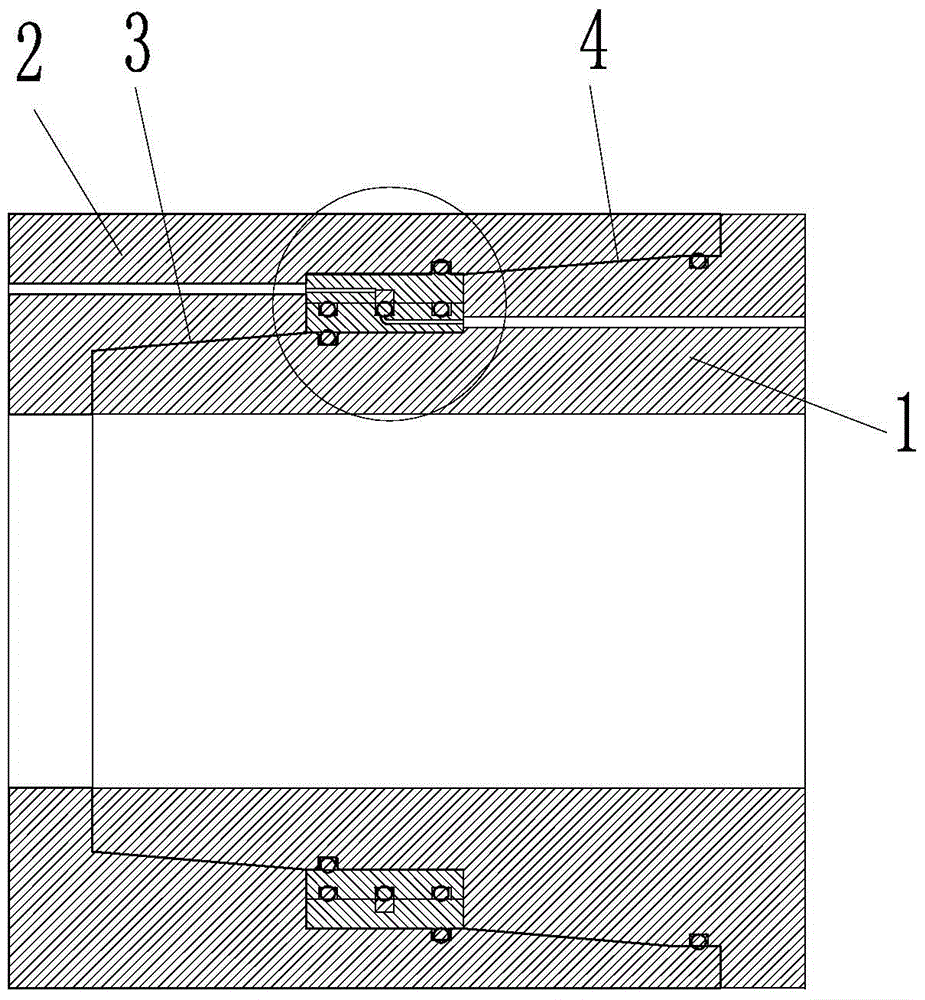

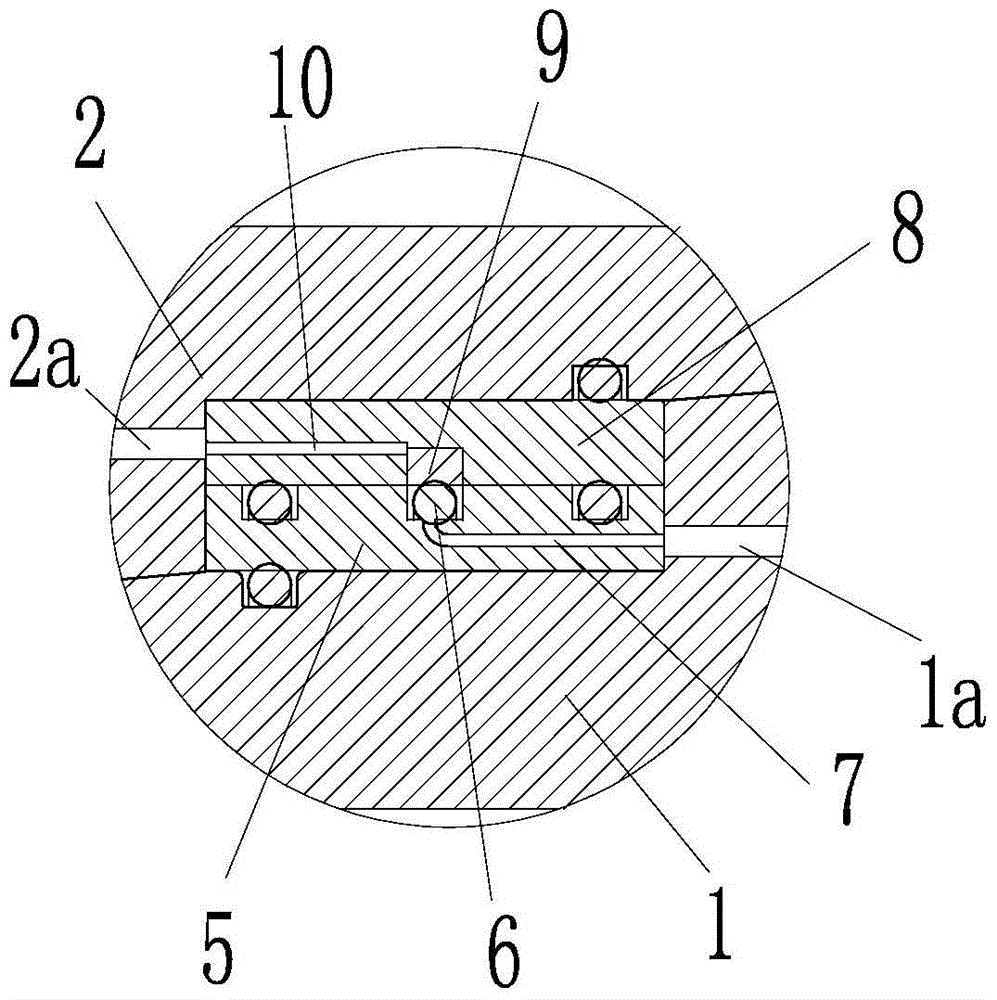

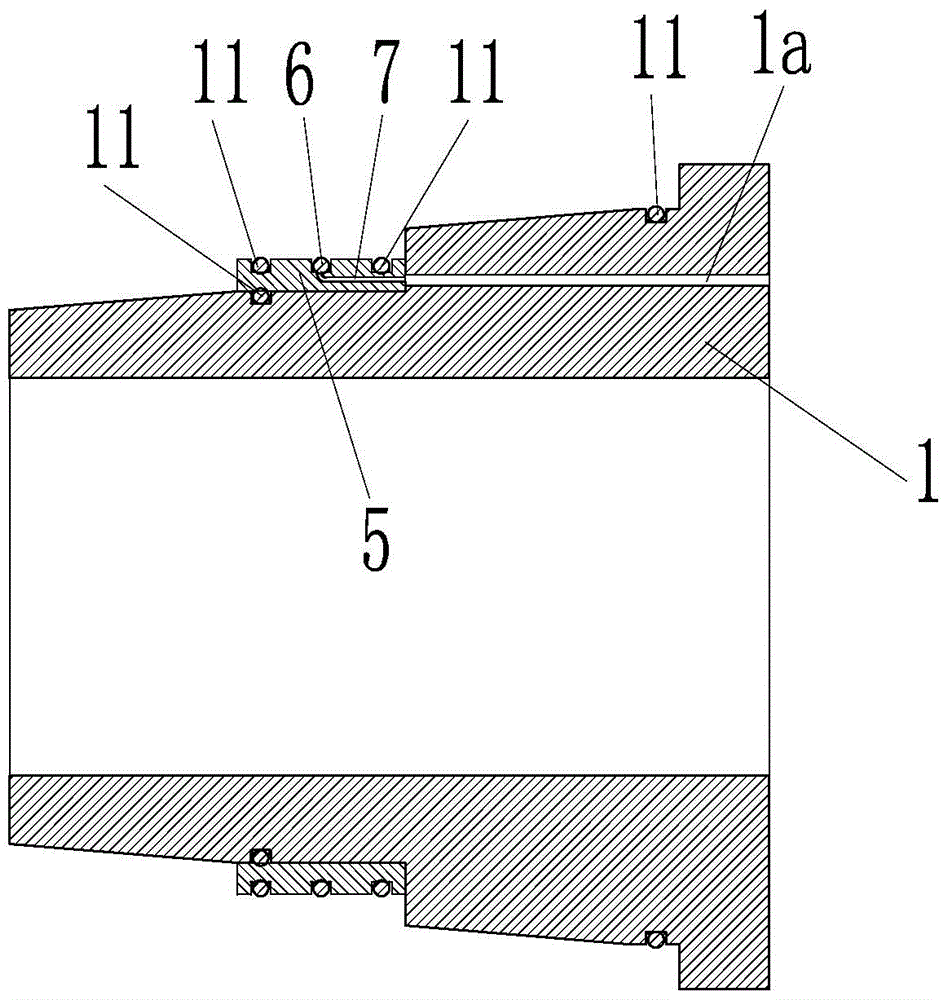

[0024] combine figure 1 — Figure 4 As shown, a fully sealed intelligent over-the-line drill pipe joint is mainly composed of a male joint 1, a female joint 2, a male joint sealing and insulating contact ring 5, a male joint metal contact body 6, a male joint embedded wire 7, and a female joint sealing insulation It is composed of a contact ring 8, a female connector metal contact body 9, a female connector pre-embedded wire 10, and a plurality of sealing rings 11.

[0025] Both the male joint 1 and the female joint 2 are metal parts, and the male joint 1 and the female joint 2 are screwed and sealed by the first thread pair 3 and the second thread pair 4 arranged at an axial interval. Preferably, the first thread pair 3 and the second thread pair 4 adopt digital threads and are airtight metal-metal thread pairs. In addition, the front end of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com