Test system for assessing freeze resistance of wind turbine blade coating, and method thereof

A testing system and technology for wind turbine blades, applied in measuring devices, analysis materials, material thermal analysis, etc., can solve the problem that the anti-freezing performance of anti-icing coatings cannot be measured comprehensively and truly, there is no standard for anti-freezing performance, and the investment in equipment is huge and other issues, to achieve the effect of reflecting the performance of coatings, accurate dynamic testing, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

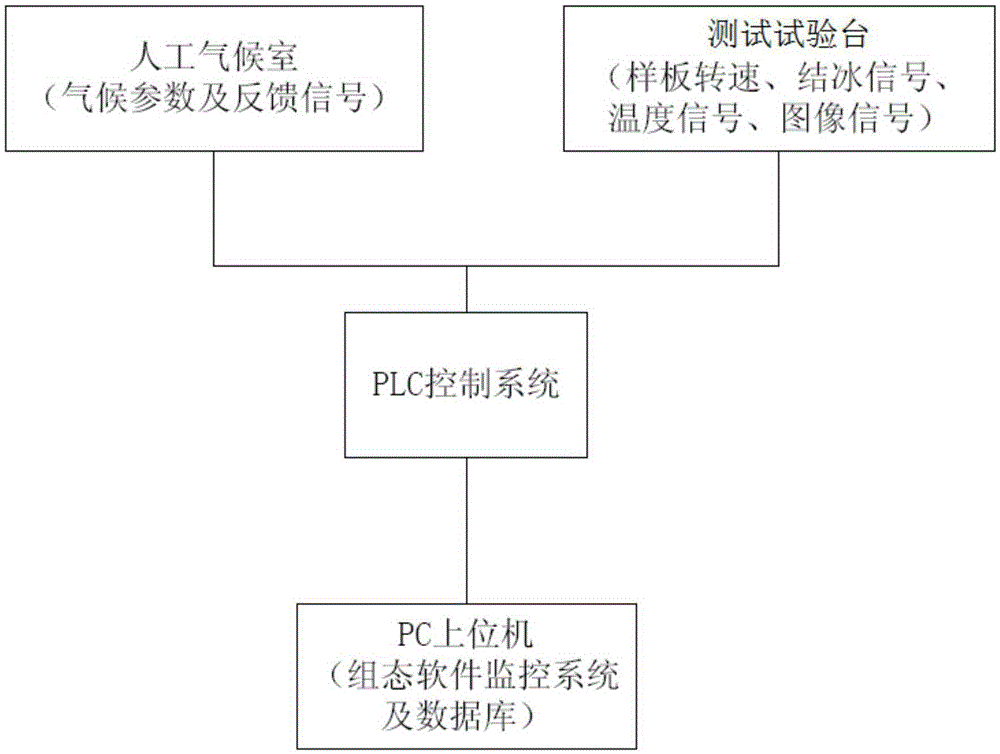

[0024] According to the freezing behavior and debonding behavior of the ice layer on the surface of the blade coating, the present invention proposes a whole-process testing system and method for the anti-freezing ability of the blade coating in a simulated natural environment, which can be used to evaluate the freezing of the anti-freezing coating behavior and ice debonding behavior, so as to comprehensively and truly measure the anti-icing performance of anti-icing coatings.

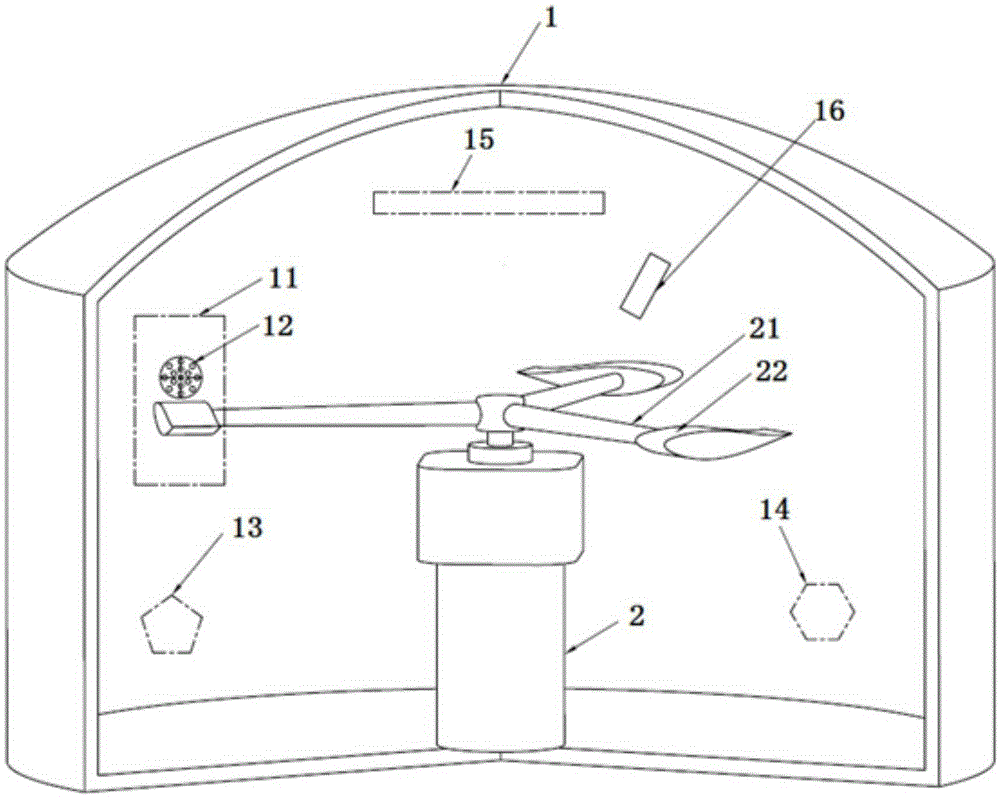

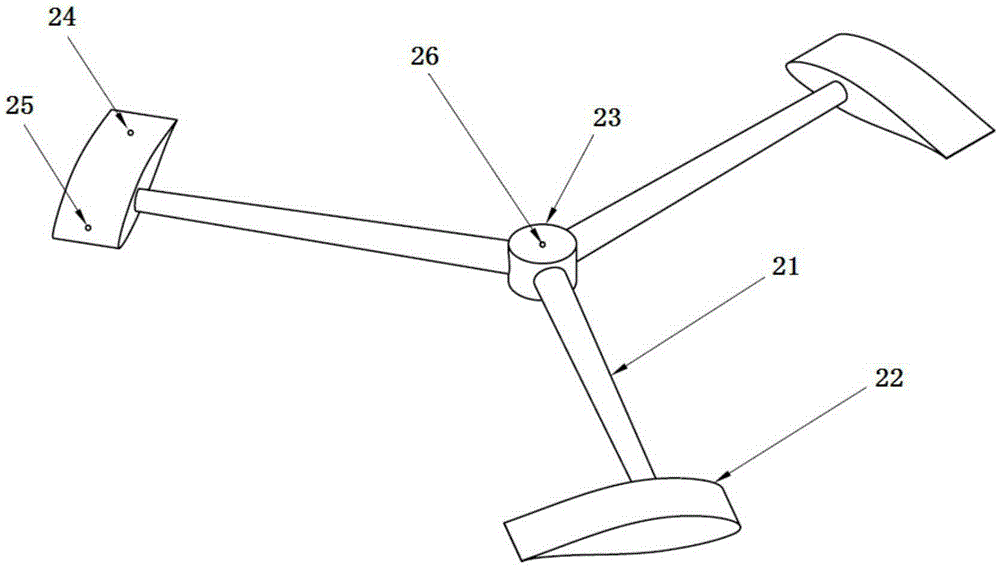

[0025] see figure 1 As shown, the present invention provides a test system for evaluating the anti-freezing performance of wind turbine blade coatings, including a set of artificial climate chamber 1, which can simulate the actual freezing environment and melting ice environment in a natural state. There are multiple environmental simulation systems in the artificial climate chamber 1, the environmental simulation systems include air supply and temperature adjustment system 11, supercooled droplet gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com