A test platform for buffer compensation system simulating heavy load wave heave

A compensation system and test platform technology, applied in ship construction, ship design, ships, etc., can solve the problems of difficult combination of hydraulic synchronous lifting equipment and buffer system, complex structure, large volume, etc., to achieve high practical value, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment uses the technical solution of the present invention

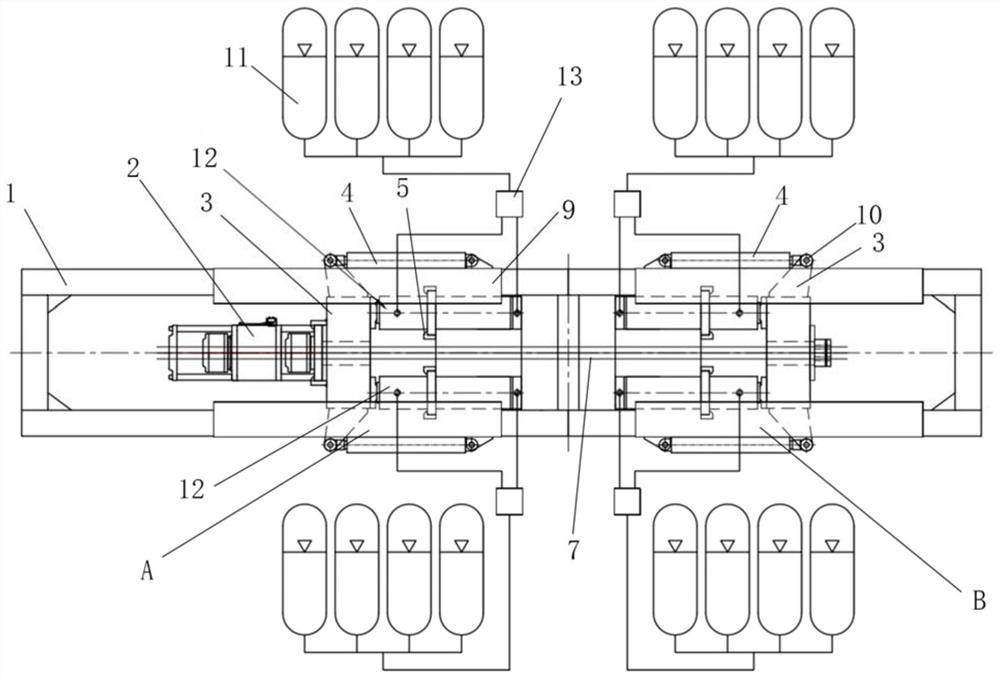

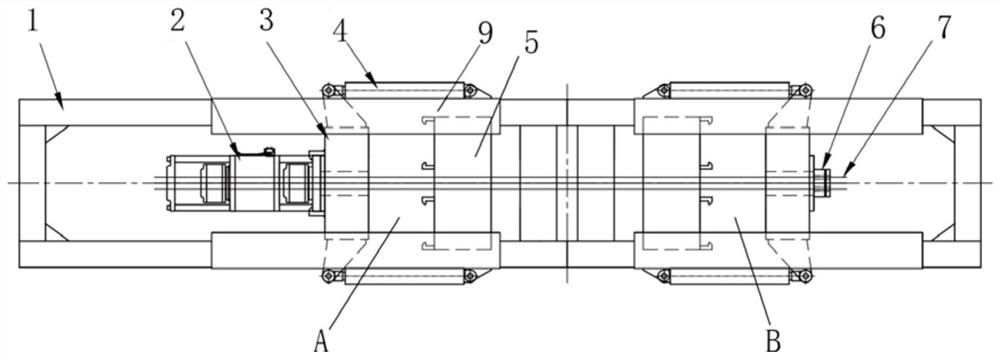

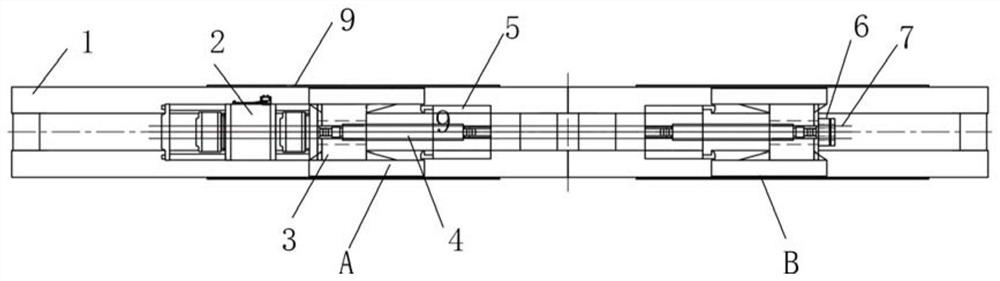

[0031] As shown in Figures 1 to 4, the present embodiment provides a buffer compensation system test plane for simulating large-load wave heave.

[0032] The structures of the first excitation unit A and the second excitation unit B are the same. The first excitation unit A includes

[0033] The buffer compensation system to be tested generally includes a buffer oil cylinder 12, an accumulator 11 and a hydraulic valve group 13. This embodiment

[0034] One end of the lifting oil cylinder 2 is fixedly connected to the ground through a bracket, and the other end is connected to the balance beam 3 of the first excitation unit A. many

[0041] The static test is shown in Figures 5a and 5b.

[0044] The dynamic test is shown in Figure 6.

[0046] The preferred embodiments of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com