Intelligent material management system

A management system and smart materials technology, applied in logistics, data processing applications, instruments, etc., can solve the problems of inconvenient daily management of staff, complicated material circulation process, and backward methods, so as to save human resources and time, save costs and Effects of manpower, difficulty of simplification, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in conjunction with the following examples.

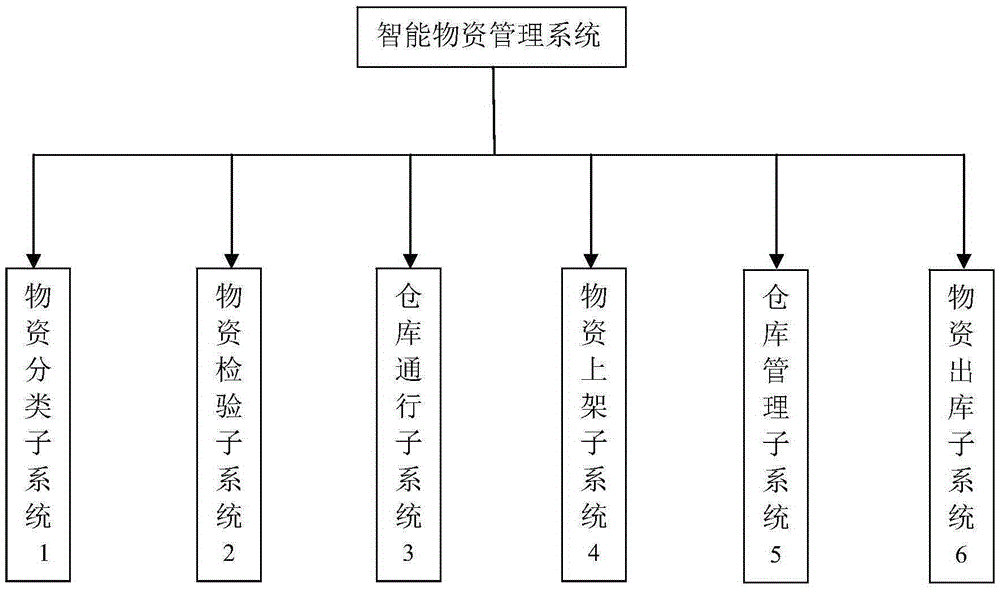

[0040] Such as figure 1 An intelligent material management system shown includes:

[0041] Material classification subsystem 1: Used to perform non-dimensional quantitative preprocessing of the acquired material logistics attribute data, such as dimensions, weight, packaging specifications, storage time limit, temperature and humidity requirements, etc., using SPSS software as the main analysis tool to complete material import Classification before the library.

[0042] Material inspection subsystem 2: Use RFID technology to perform target identification and data exchange through wireless two-way data transmission between the reader and radio frequency card, bind the information of the goods and vehicles, and track and locate the vehicle through GPS technology. Determine the inspection type and quantity of materials to be inspected; the inspection of materials adopts a random samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com