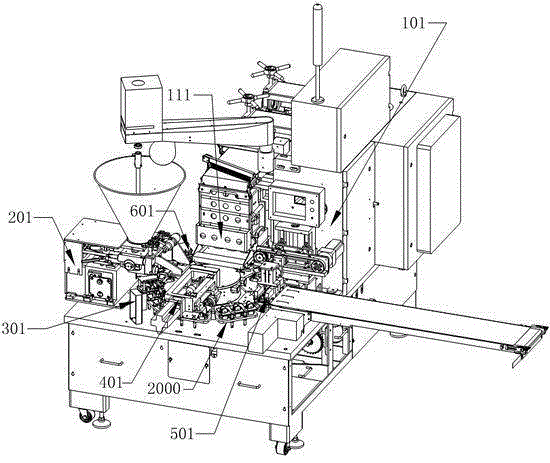

Double-layer-wrapper multi-stuffing encrusting food moulding method

A double-layer skin and food forming technology, which is applied in the fields of dough processing, food science, baking, etc., can solve the problems of injection, the inability to realize solid filling and liquid filling, and the inability to realize multiple filling injections, so as to avoid damage , the effect of a variety of fillings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

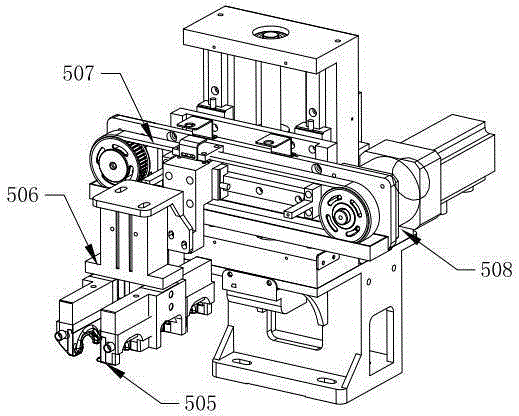

[0109] A method for forming a double-layered skin with multiple fillings for stuffing food, the specific steps are:

[0110] In the first step, the first dough is tiled at the first skin receiving station 100;

[0111] In the second step, the first dough is transported to the second skin receiving station 110, and at this time the second dough is spread on the first dough;

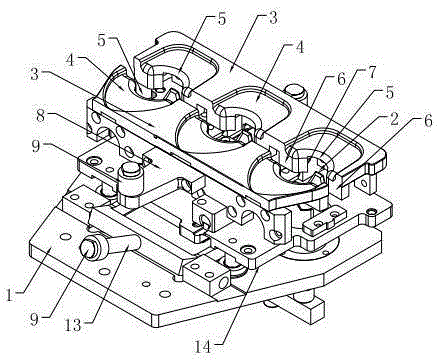

[0112] In the third step, the second dough and the first dough are stacked on each other, and at the same time, after preliminary molding, the first dough is wrapped around the outside of the second dough, forming a pocket shape; the pocket shape means that the dough is concave, and the surface of the dough The surrounding is sealed and the top of the dough is open;

[0113] In the fourth step, the pocket-shaped first dough and the second dough are located at the first filling station 200, and the concave part of the pocket-shaped second dough is injected with filling A;

[0114] In the fifth step, the p...

Embodiment 2

[0122] A method for forming a double-layered skin with multiple fillings for stuffing food, characterized in that: the specific steps are:

[0123] In the first step, the first dough is tiled at the first skin receiving station 100;

[0124] In the second step, the first dough is transported to the second skin receiving station 110, and at this time the second dough is spread on the first dough;

[0125] In the third step, the second dough and the first dough are stacked on each other, and at the same time, after preliminary molding, the first dough is wrapped around the outside of the second dough, forming a pocket shape; the pocket shape means that the dough is concave, and the surface of the dough The surrounding is sealed and the top of the dough is open;

[0126] In the fourth step, the pocket-shaped first dough and the second dough are located at the first filling station 200, and the concave part of the pocket-shaped second dough is injected with filling A;

[0127] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com