Shock-absorbing non-slip sole

A non-slip and bottom surface technology, applied in the direction of shoe soles, footwear, clothing, etc., can solve the problems of unsatisfactory shock absorption and cushioning effect, cumbersome production process, and large size of shoe soles, and achieve improved protection, good wrapping, and enhanced lateral direction The effect of anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

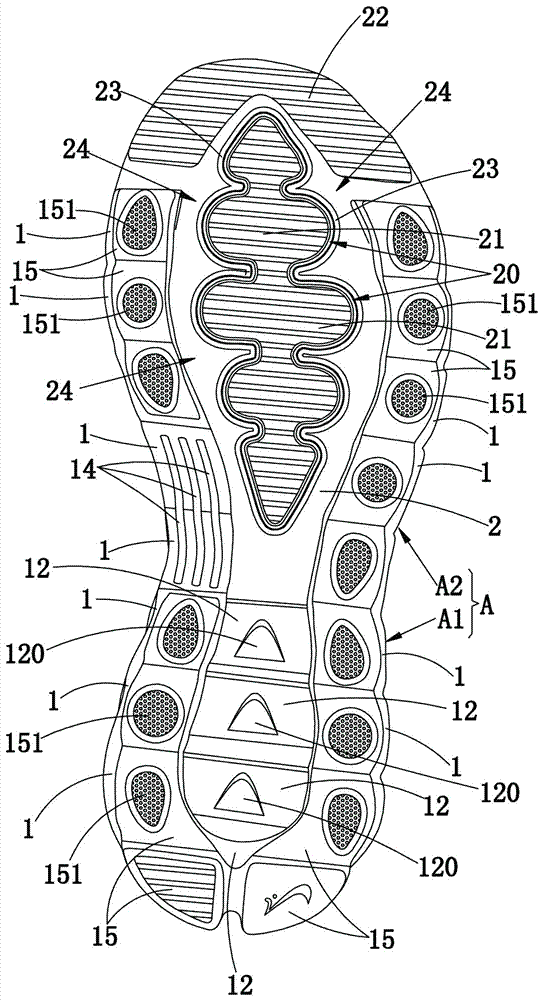

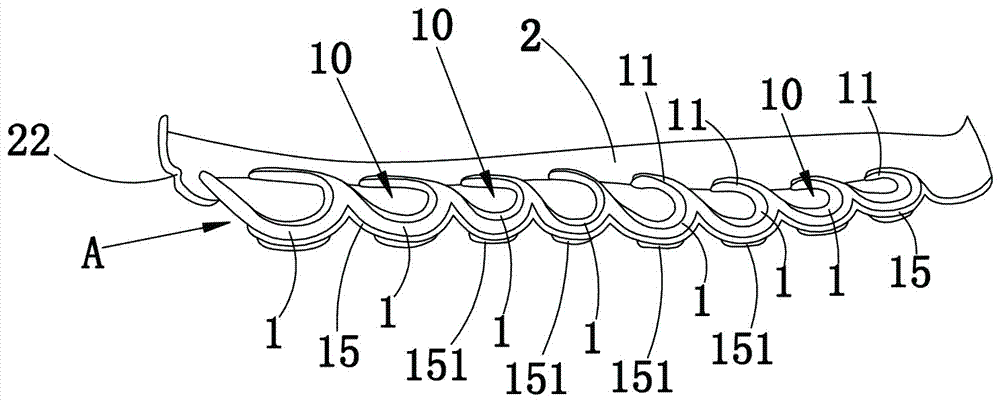

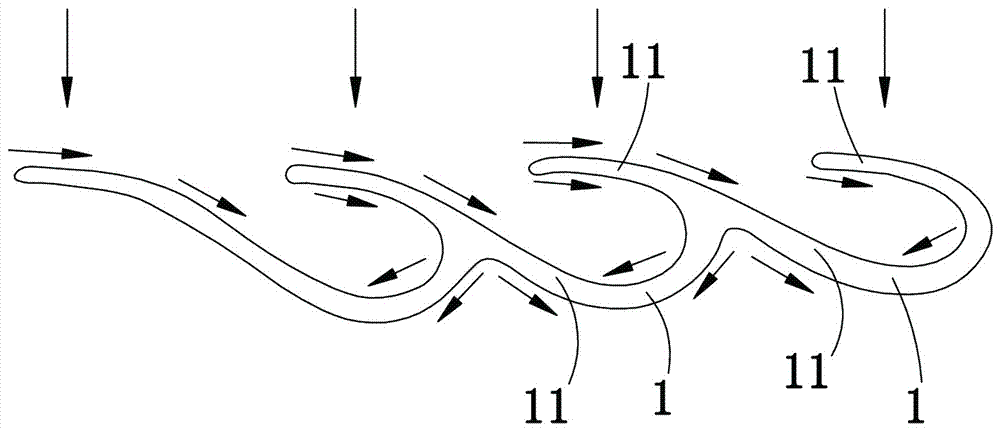

[0024] refer to figure 1 , figure 2 , Shock-absorbing antiskid sole, it comprises midsole 2 and the cushioning body A that is assembled in midsole 2, and midsole 2 is preferably EVA midsole. The cushioning body A is composed of a plurality of unit bodies 1, preferably the unit bodies 1 are made of TPU material. A plurality of unit bodies 1 are connected sequentially in a U-shape arrangement. The unit body 1 is an elastic member curved in a C shape. The opening of the unit body 1 faces backwards. The top surfaces of the two ends 11 of the unit body 1 are Bond with midsole 2. like Figure 2 to Figure 4 As shown in any drawing, the adjacent two end portions 11 of two adjacent unit bodies 1 are integrally connected. Each unit body 1 is bent to form a slot 10 extending along the width direction of the midsole 2 . The palm of the bottom surface of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com