Disc-type centrifuge rotary drum with wear-resistant lining

A disc centrifuge and wear-resistant lining technology, applied in the direction of centrifuges, etc., can solve the problems of easy wear and tear of the slag discharge port of the drum body, and achieve the effects of convenient assembly operation, accurate efficiency and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

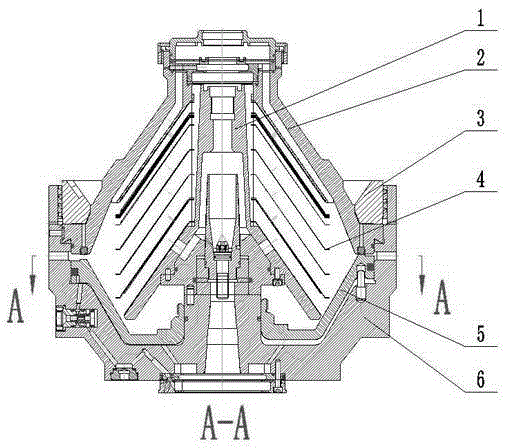

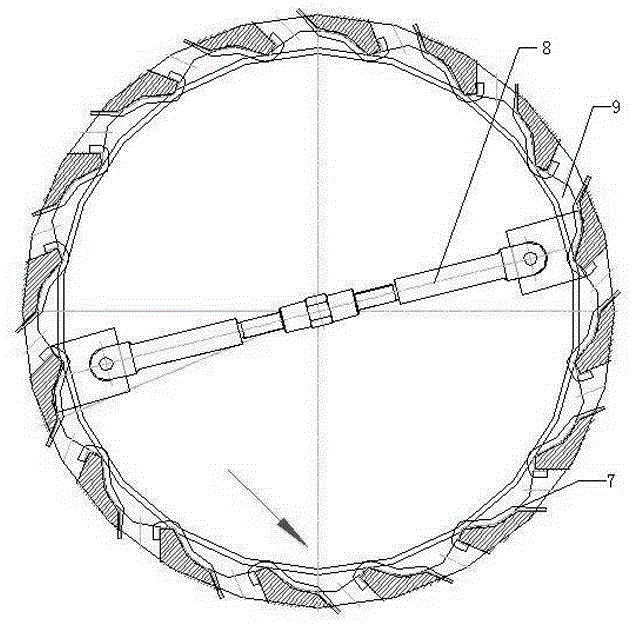

[0017] Such as figure 1 , figure 2 with image 3 A disc centrifuge drum with a wear-resistant lining is shown, including a drum body 6, and a drum cover 2 fixed on the drum body 6 by a lock ring 3, and a drum cover 2 arranged on the drum body 6 to rotate Inside the drum cover 2 there is a sliding piston 5 and a distributor 1 from bottom to top, and a set of discs 4 are arranged around the distributor 1, wherein the discs 4 are set on the distributor 1 and set at the slag discharge port 9 of the drum body The wear-resistant lining 7 at the place; the drum body 6, the drum cover 2, the sliding piston 5 and the distributor 1 are coaxial.

[0018] Further preferably, a set of discs 4 is 70-200 sheets, and the disc centrifuge drum with wear-resistant lining also includes a positioning rod 8 for installing the wear-resistant lining 7, wherein the wear-resistant lining 7 is placed Place it on the slag discharge port 9 of the drum body, first fix it with the positioning rod 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com