Main propeller hub and propeller shell assembly dismounting tool and method

A technology for dismantling tools and main propeller hubs, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as scrapped parts, deformation of upper and lower star plates, and strained bearings, and achieves convenient operation, simple structure, and improved disassembly The effect of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

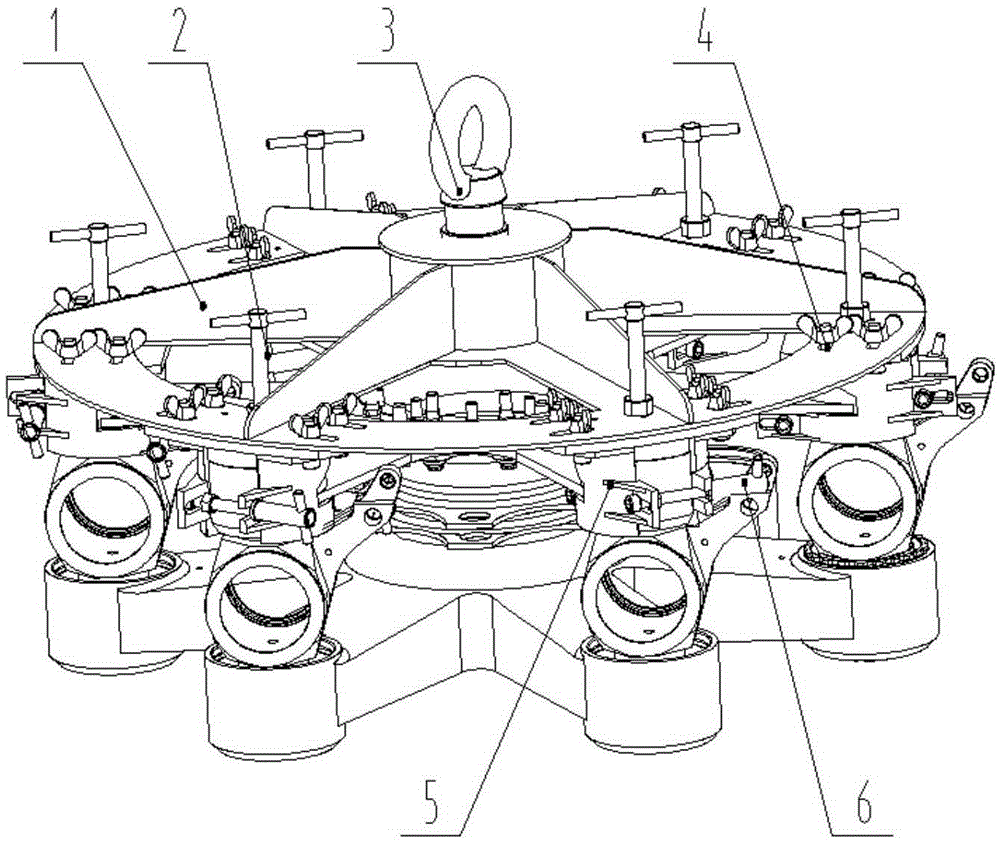

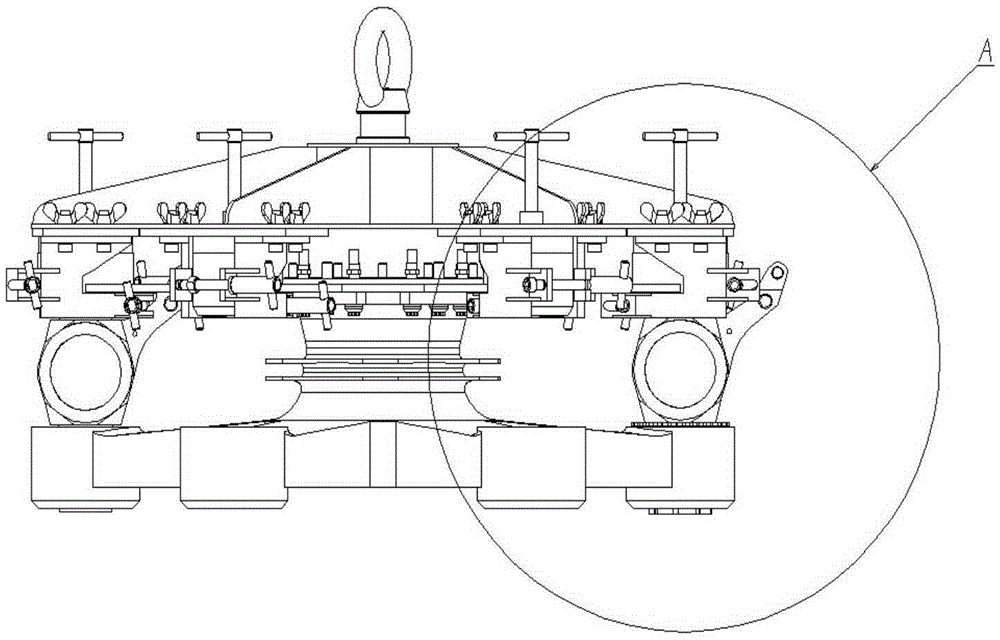

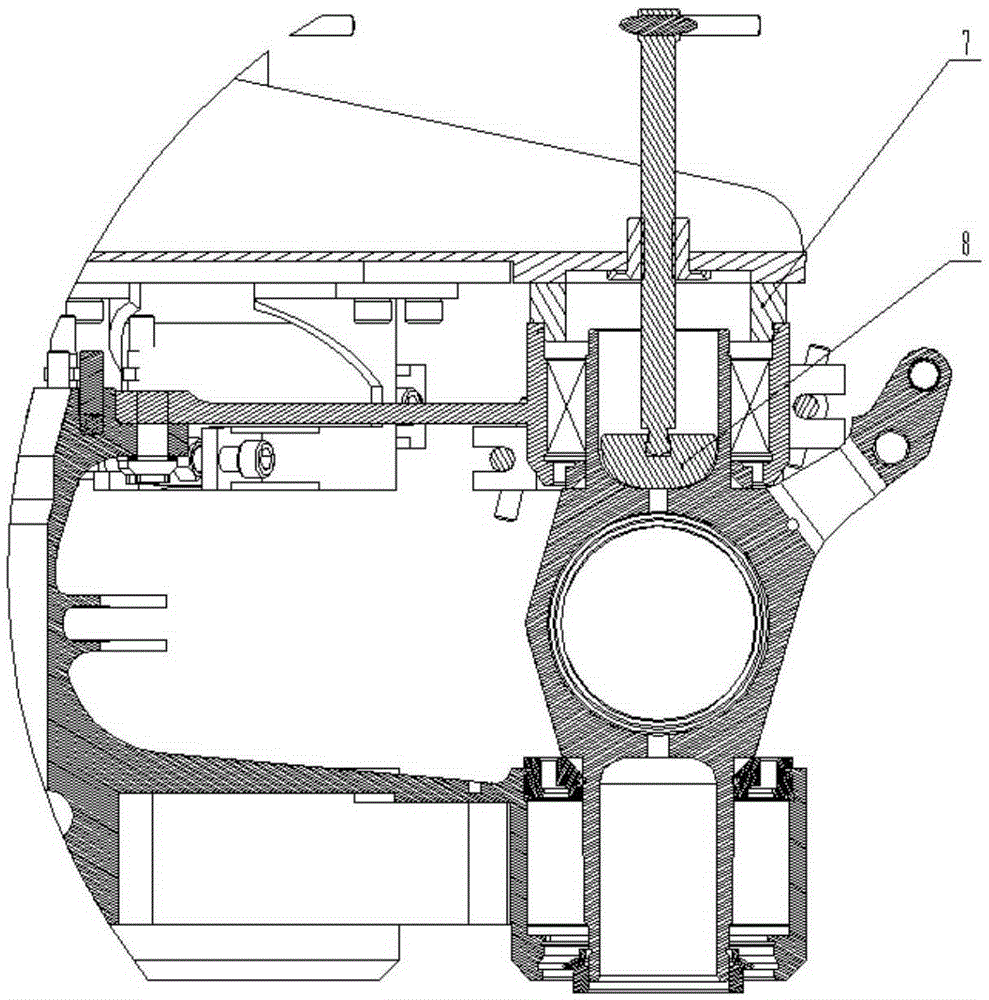

[0023] The present invention will be described in further detail below. see figure 1 , figure 2 , image 3 , the present invention includes designing and manufacturing the main body bracket 1, designing and manufacturing the adjusting screw rod 2, designing and selecting the main lifting ring 3, designing and manufacturing the opening and closing adjustment part 4, designing and manufacturing the half-ring connector 5, designing and manufacturing the clamping part 6 1. Design and manufacture positioning sleeve 7, design and manufacture briquetting block 8. The connection is made by means of bolts.

[0024] The main body bracket 1 includes a circular plate assembly, a reinforcing plate, a ring plate and a casing welded together; the adjusting screw 2, the top block 8 and the fixed screw sleeve are threaded together to form a top pressure regulating mechanism, and the rotating When adjusting the handle of the screw rod 2, the thread pair consisting of the screw rod and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com