Formation device and method for in-cavity polyurethane foamed aluminum profile

A molding equipment and polyurethane technology are applied in the molding equipment and the molding field of polyurethane foamed aluminum profiles in the cavity, which can solve the problems of low strength of aluminum profiles, gaps at the joints of aluminum profiles, and reduced thermal insulation effect, etc. The effect of good thermal effect, fast production line speed and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

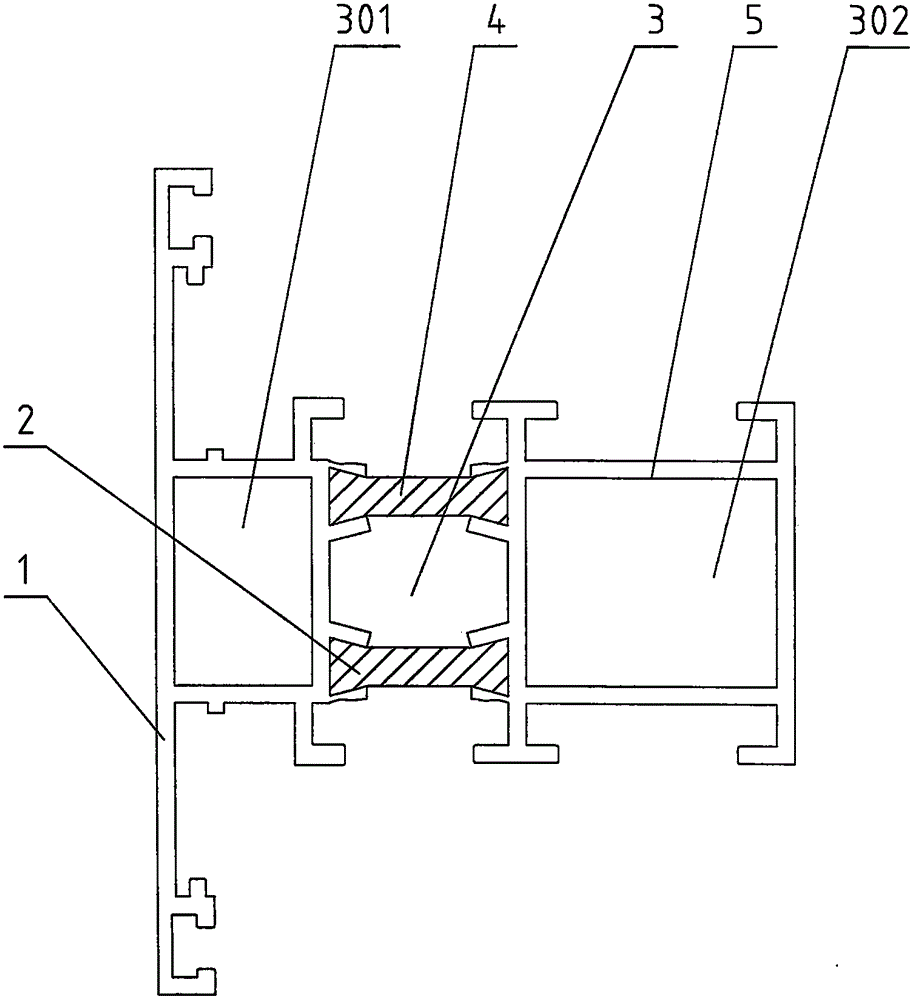

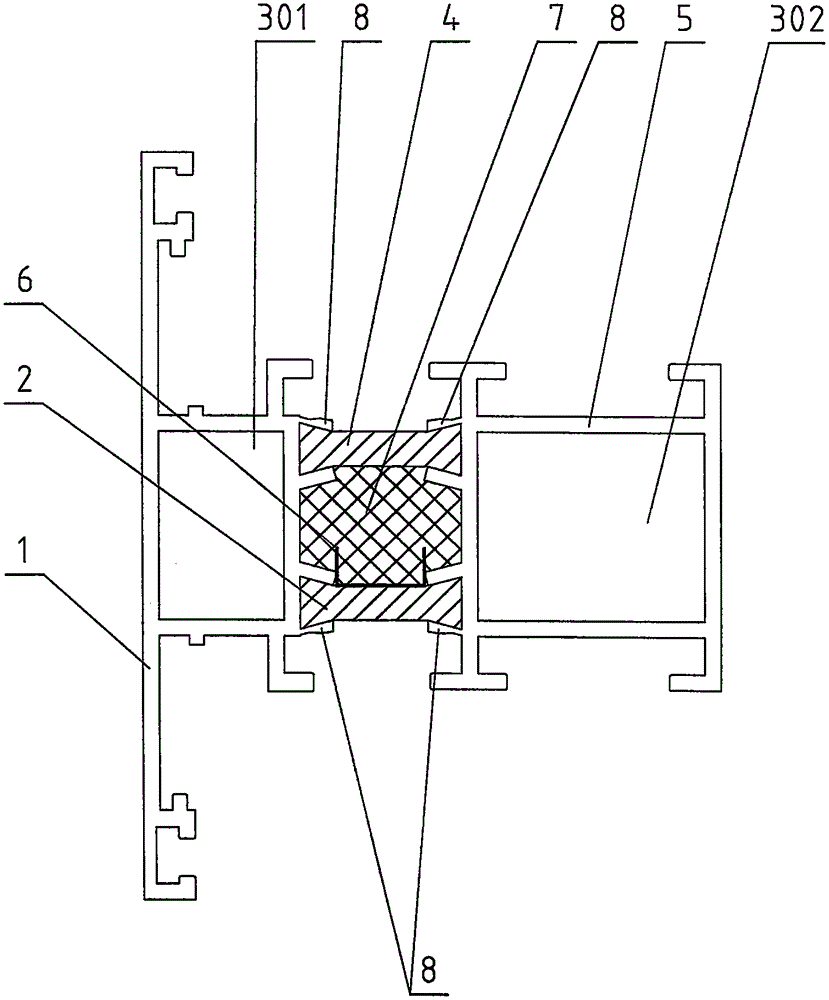

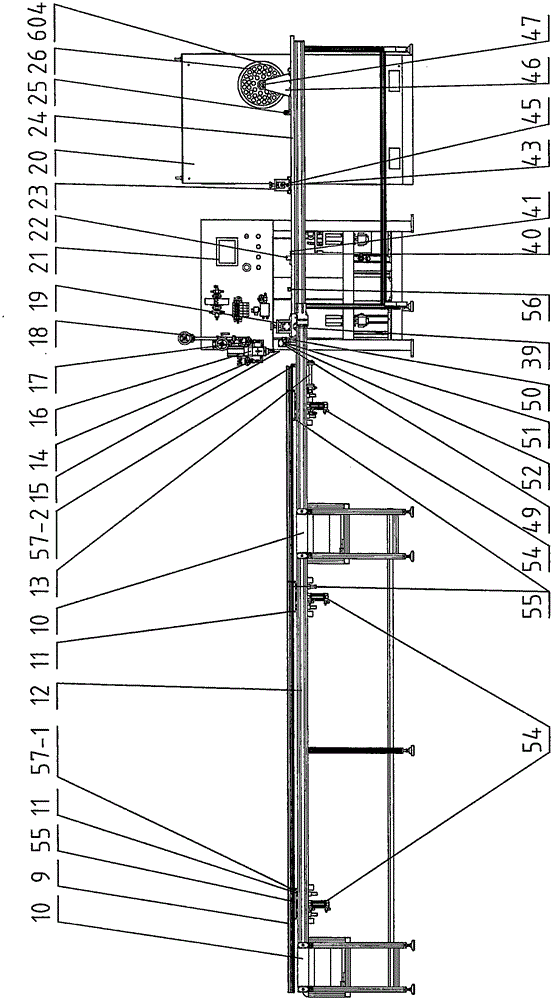

[0026] Specific implementation mode one: as figure 1 , 2 , 3, 4, 6, 7, 8, 9, and 10 show an in-cavity polyurethane foam aluminum profile forming equipment, which is used for online rapid and automatic production of in-cavity polyurethane foam aluminum profiles, and the forming equipment includes aluminum profiles Conveyor line 12, glue supply device 27, paper U-shaped strip forming device 24, control device; paper U-shaped strip forming device 24 includes an unwinding device 26, a former 22, a traction device 19, and a frame that are sequentially arranged on the workbench , it is characterized in that: molding device 22 comprises the outer mold 40 that inner cavity is trumpet shape and the core mold 41 that inserts wherein, the shape of core mold 41 follows the inner cavity of outer mold 40, the inlet end core mold 41 of molding device 22 and The sectional shape of the slit of the outer mold 40 is a straight slit, and the sectional shape from the inlet end to the outlet end ...

specific Embodiment approach 2

[0029] Specific implementation mode two: as figure 1 , 2 , 3, 4, 6, 7, 8, 9, and 10, in this embodiment, it also includes more than one paper guide 56 arranged in series between the traction device 19 and the former 22, and the convex mold 37 is located at the concave mold 35 and fixed with screws 36, the gap B38 between the die 35 and the punch 37 is used for forming or shaping the U-shaped paper strip 602, and the paper strip 601 gradually transitions to the open trapezoid 38-1 or the upper side open rectangle or U shape Or the shape of the cross-section gap B38, so that the shape before it enters the traction device 19 is the shape of the cross-section C48-3 or cross-section B48-2, and the entrance of the gap is smoothly transitioned. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: as figure 1 , 2 , 3, 4, 5, 7, 8, 9, and 10, in this embodiment, an in-cavity polyurethane foam aluminum profile molding equipment is used for online rapid and automatic production of in-cavity polyurethane foam aluminum profiles, The forming equipment includes an aluminum profile conveying line 12, a glue supply device 27, a paper U-shaped strip forming device 24, and a control device; the paper U-shaped strip forming device 24 includes an unwinding device 26, a paper guide 56, and Traction device 19, frame, it is characterized in that: more than one paper guide 56 that is arranged in series, punch 37 is positioned on die 35 and is fixed with screw 36, the slit B38 between die 35 and punch 37 is used for forming or Shape the U-shaped paper strip 602, and the paper strip 601 gradually transitions to the open trapezoid 38-1 or the upper side open rectangle or U-shape or the shape of the cross-section gap B38, so that the shape before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com