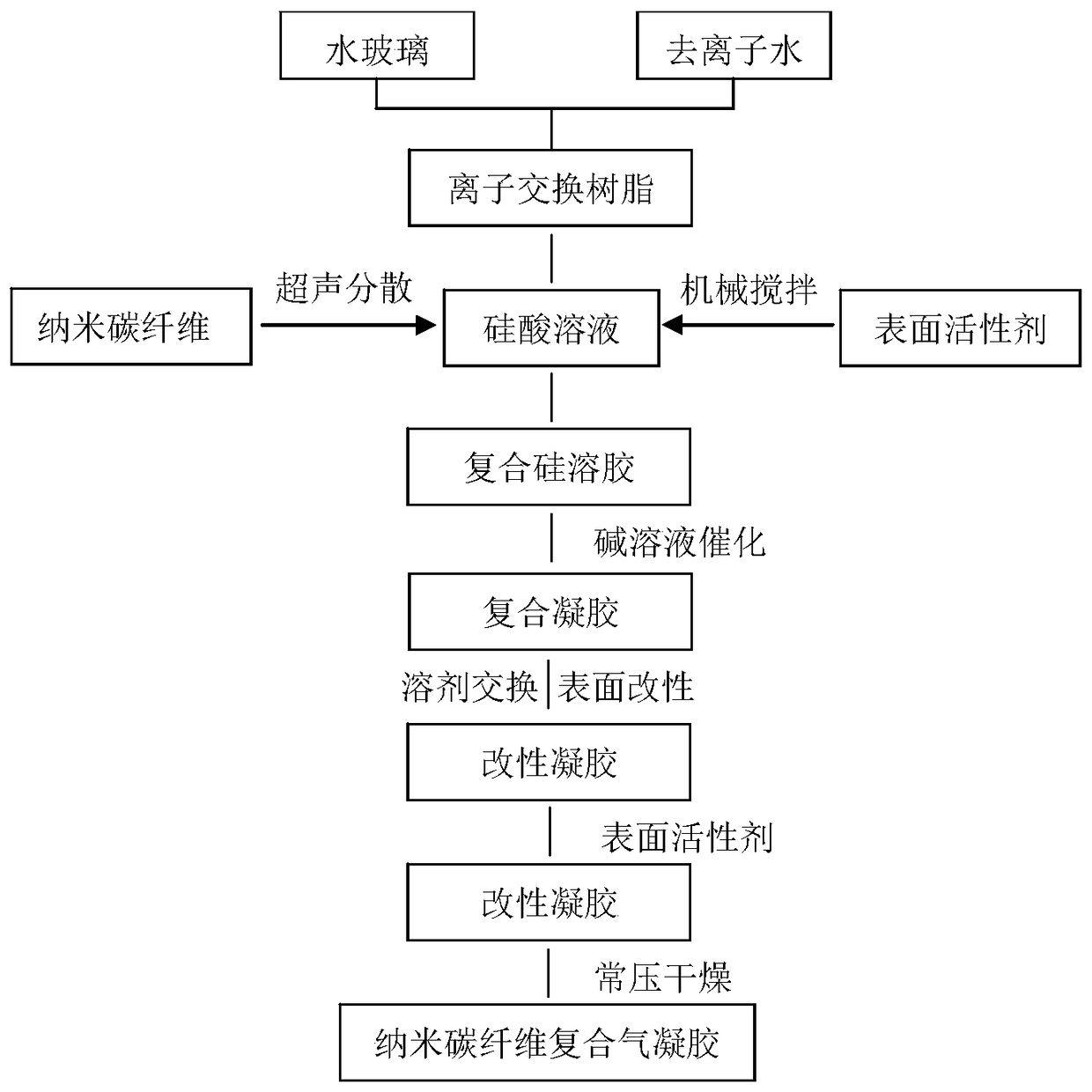

A preparation process of nano-carbon fiber composite silica airgel

A technology of carbon nanofibers and composite silicon oxide, which is applied to the preparation of inorganic nanocomposite materials and thermal insulation materials, and the field of nanometer mesoporous materials, can solve the problems such as the entanglement and agglomeration of carbon nanofibers are not easy to disperse, so as to avoid structural damage and stress concentration, The effect of short production cycle and improved pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dilute water glass (modulus about 3.1 Baume degree is about 40) with deionized water at a volume ratio of 1:2, perform ion exchange through a strongly acidic styrene-based cation exchange resin, and remove sodium ions to obtain a silicic acid solution. Using sodium dodecyl sulfate (SDS) and cetyltrimethylammonium bromide (CTAB) as dispersant, according to the mass ratio of (SDS+CTAB):CNFs=8:1, ultrasonic in silicic acid solution Disperse for 30 minutes, and use 3.0mol / L ammonia water to catalyze the gel. The gel was aged at room temperature for 12 hours, then moved into 50% methanol solution for 12 hours, and then immersed in 100% methanol for 12 hours to exchange part of pore water. Use ethanol, n-hexane, trimethylchlorosilane for solvent exchange / surface modification, the molar ratio of ethanol to trimethylchlorosilane is 2:3, the volume ratio of trimethylchlorosilane to wet gel is 1:1, time for 24h. The samples were taken out and washed with SDS+CTAB solution to re...

Embodiment 2

[0036]Water glass (modulus about 2.9 Baume degree is about 30) is diluted with deionized water at a volume ratio of 1:6, and ion exchange is performed drop by drop through a strong acidic styrene-based cation exchange resin to remove sodium ions to obtain silicon acid solution. Using methyl cellulose (MC) and sodium dodecylbenzenesulfonate (SDBS) as dispersants, according to the mass ratio of (MC+SDBS): CNFs = 4:1, ultrasonically disperse in silicic acid solution for 20min, use 1.0mol / L lithium hydroxide solution catalyzed the gel. After the gel was formed, it was aged at room temperature for 12 hours, then moved into 50% ethanol solution and soaked for 12 hours, and then moved into 100% ethanol solution for 12 hours to exchange part of pore water. Then carry out solvent exchange / surface modification with ethanol, n-hexane, trimethylchlorosilane, the molar ratio of ethanol to trimethylchlorosilane is 1:1, and the volume ratio of trimethylchlorosilane to wet gel is 1.5:1, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com