Method and device for producing 3,4-dichloronitrobenzene through continuous kettle type reaction

A technology for dichloronitrobenzene and p-chloronitrobenzene is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve problems such as prolonged production cycle, increased production cost, material and energy loss, etc. , to achieve the effect of simple process operation, low production cost and high level of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

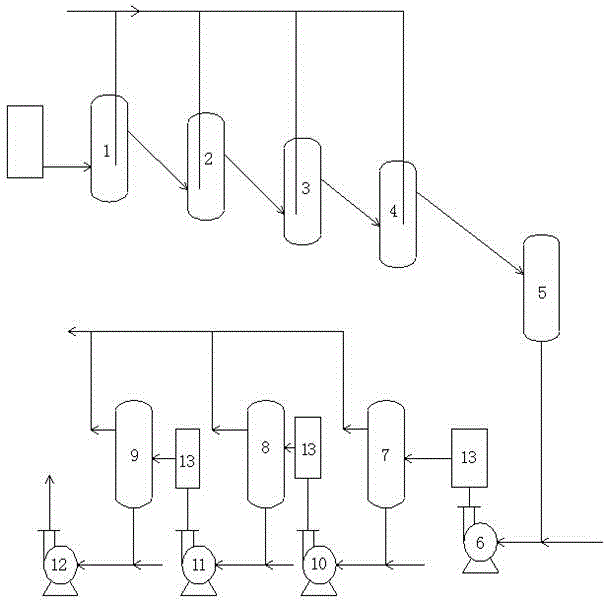

[0020] Accompanying drawing is a kind of specific embodiment of the present invention. The device for producing 3,4 dichloronitrobenzene by continuous tank reaction described in this embodiment includes reactor A1, reactor B2, reactor C3 and reactor D4 connected in series and having a liquid level difference before and after, and reactor D4 is connected to the storage tank 5, the storage tank 5 is connected to the washing kettle A7 through the mixing pump A6, the washing kettle A7, the washing kettle B8, and the washing kettle C9 are connected in series through the mixing pump B10 and the mixing pump C11 in sequence, and the outlet of the washing kettle C9 is provided with a liquid pump 12; the reactor A1, reactor B2, reactor C3 and reactor D4 are equipped with outer jacket, chlorine distribution pipe and stirring device; the reactor A1, reactor B2, reactor C4 and reactor D6 The horizontal position of each reactor lowers 8-25% of its own height successively; Described reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com