A method for separating uranium during gallium treatment in Bayer process alumina production

A technology of treatment process and separation method is applied in the field of separation of uranium in the process of gallium treatment in the production of alumina by the Bayer process, and can solve the problems of low uranium content, complex matrix components, and complicated gallium production process flow, and achieve high product purity. , Improve the purity and quality, the effect of thorough elution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

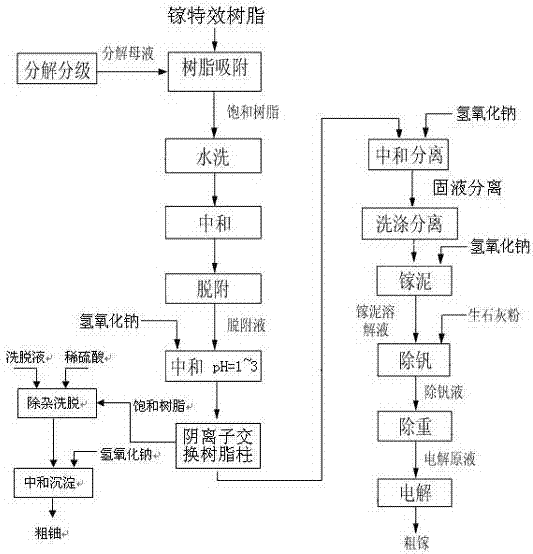

Image

Examples

Embodiment 1

[0030] The method for separating uranium in the gallium treatment process in the Bayer process alumina production of the present invention comprises the following steps:

[0031] A. Neutralize the sulfuric acid desorption solution of 100 m³ gallium with solid sodium hydroxide to pH=1.0, and the content of uranium in the solution is measured to be 40 μg / mL;

[0032] B. The neutralized solution in step A flows through the pretreated two-stage fixed bed KN type strong basic anion resin, the ion exchange column size is φ500 mm×2000 mm, the ion exchange resin column bed height is 1.6 m, and the flow rate is 4 m³ / h, adopt the method of circulating the uranium-containing solution through the column until the content of uranium in the solution is less than 1 μg / mL;

[0033] C. The column liquid is neutralized with solid sodium hydroxide to pH = 5.0 to obtain gallium mud precipitation. The gallium mud is dissolved in sodium hydroxide solution to obtain a gallium mud solution. Quicklim...

Embodiment 2

[0037] The method for separating uranium in the gallium treatment process in the Bayer process alumina production of the present invention comprises the following steps:

[0038] A. Neutralize the sulfuric acid desorption solution of 100 m³ gallium with sodium hydroxide solution to pH=1.5, and the content of uranium in the solution is measured to be 32 μg / mL;

[0039] B. The neutralized solution in step A flows through the pretreated single-stage fixed bed KN type strong basic anion resin, the ion exchange column specification is φ500 mm×2000 mm, the ion exchange resin column bed height is 1.6 m, and the flow rate is 5m³ / h. Adopt the method of circulating the uranium-containing solution through the column until the content of uranium in the solution is less than 1 μg / mL, and then stop the circulation;

[0040] C. The column liquid is neutralized with solid sodium hydroxide to pH = 6.0 to obtain gallium mud precipitation. The gallium mud is dissolved in potassium hydroxide solu...

Embodiment 3

[0044] The method for separating uranium in the gallium treatment process in the Bayer process alumina production of the present invention comprises the following steps:

[0045] A. Neutralize the sulfuric acid desorption solution of 100 m³ gallium with solid sodium hydroxide to pH=2.0, and the content of uranium in the solution is about 18 μg / mL;

[0046] B. The neutralization solution in step A flows through the pretreated single-stage fixed bed KN type strong basic anion resin, the ion exchange column size is φ500 mm×2000 mm, the ion exchange resin column bed height is 1.6 m, and the flow rate is 3 m³ / h , take the method of circulating the uranium-containing solution through the column until the content of uranium in the solution is less than 1 μg / mL, and stop the circulation;

[0047] C. The column solution is neutralized to pH=8.0 with sodium hydroxide solution to obtain gallium mud precipitation, and the gallium mud is dissolved in sodium hydroxide solution to obtain a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com