Designing method for valve port of rotary valve

A design method and technology of rotary valve, applied in the direction of calculation, earthwork drilling, special data processing applications, etc., can solve the problem that it does not have the characteristics of wave propagation, cannot provide effective solutions and solutions, and does not explain the theoretical basis for valve port design. and design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

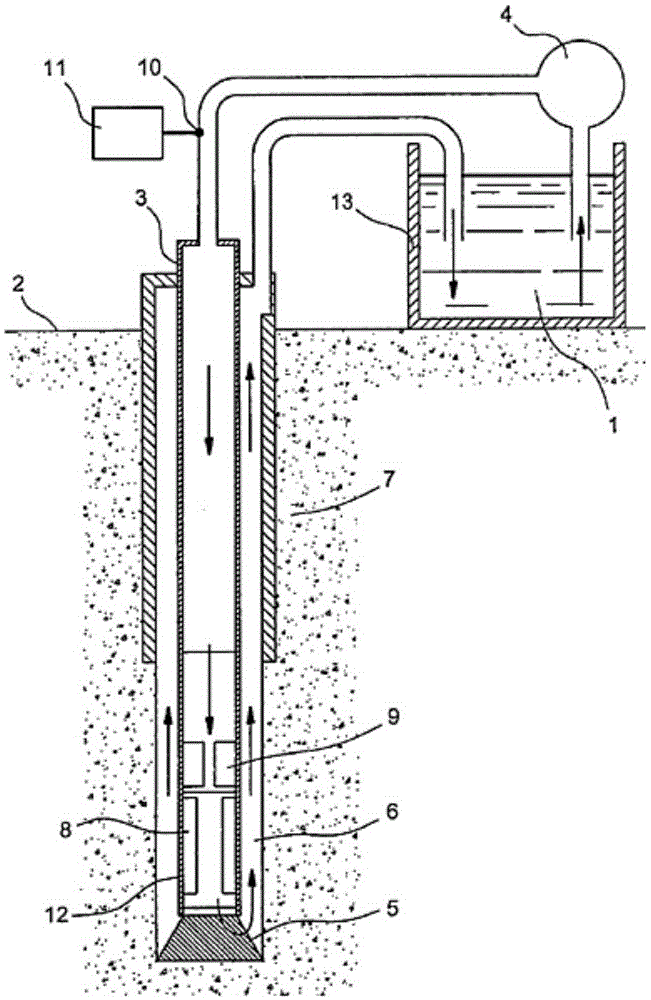

[0046] figure 1 Shown is an existing drilling device including a measurement-while-drilling / logging-while-drilling tool and a drilling fluid continuous pressure wave signal generator. The drilling fluid 1 in the drilling fluid tank 13 is injected into the drill string 3 drilled into the formation 7 through the drilling fluid pump 4 on the ground 2, reaches the drill bit 5 at the bottom of the drill string 3, and passes through the drill string 3 and the formation 7 after flowing out from the water hole of the drill bit. The annular space 6 between returns to the surface 2, and the arrow indicates the flow path of the drilling fluid.

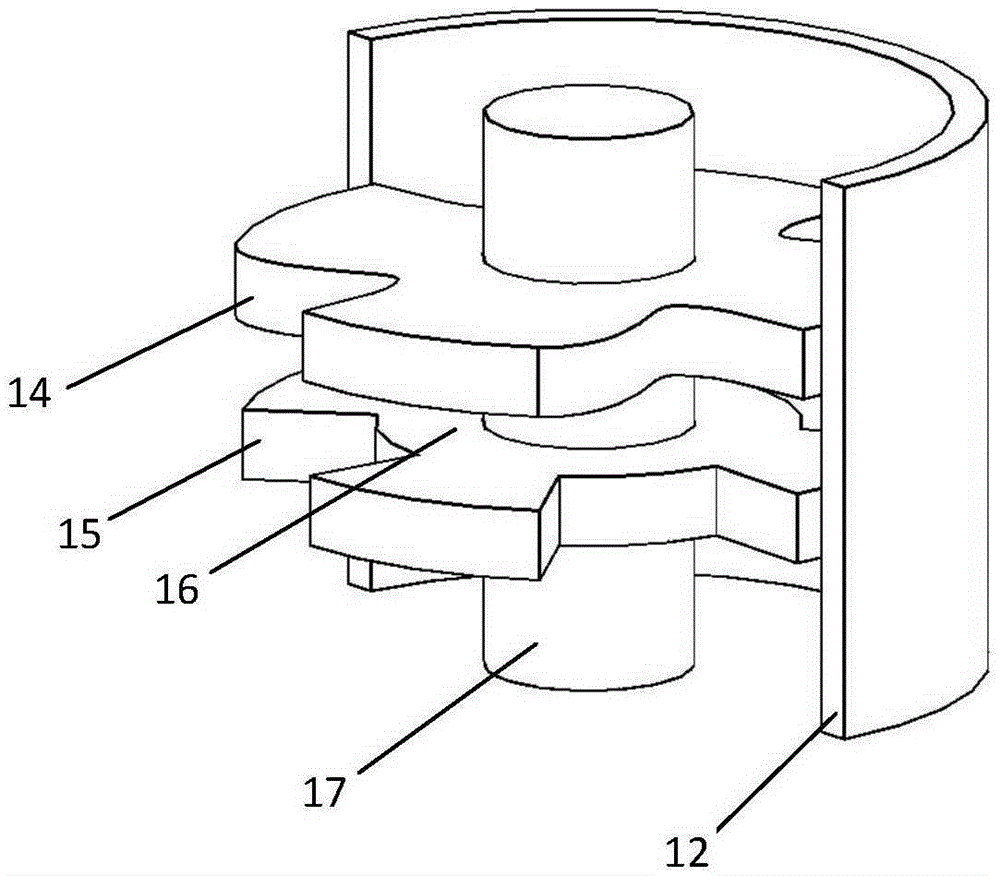

[0047] Instruments are placed in the drill collar 12 close to the drill bit 5 in the drill string 3 , and the upper part of the drill collar is connected to the drill pipe to form a drill string. The entire drill string a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com