Vaporized Fuel Processing Apparatus

一种蒸发燃料、处理装置的技术,应用在蒸发燃料处理装置领域,能够解决吸附材料温度下降等问题,达到提高脱离效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

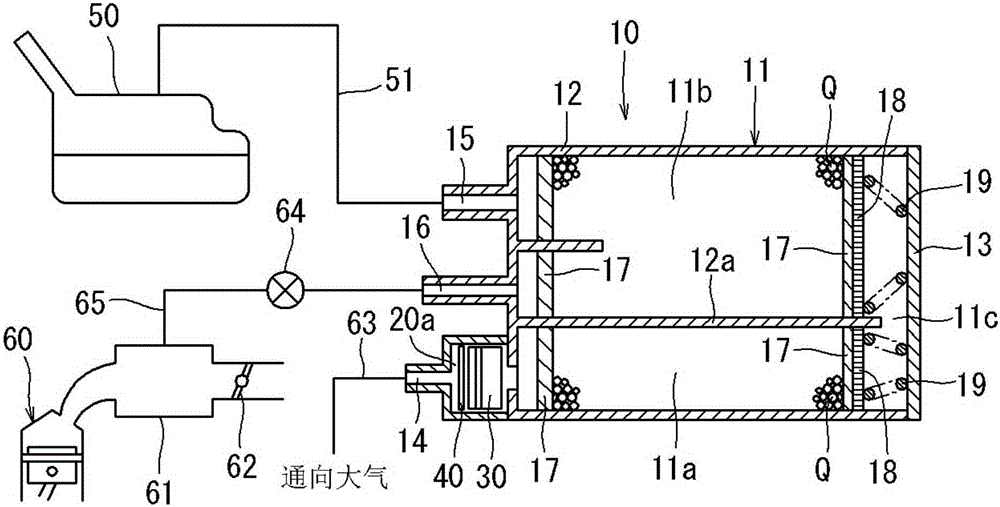

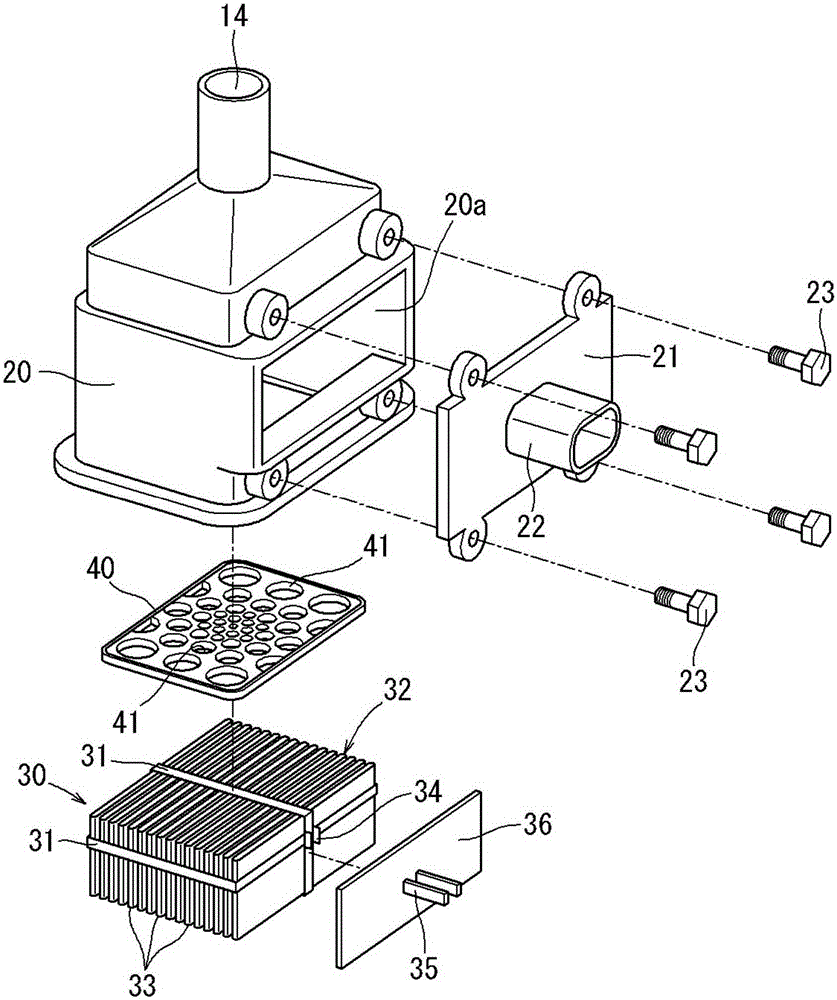

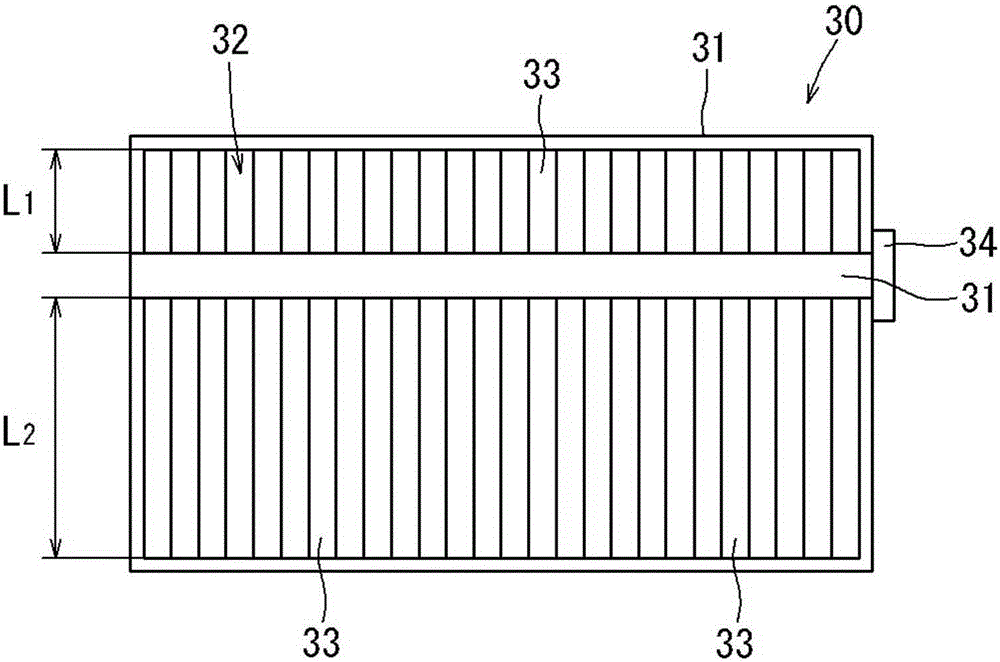

[0034] Hereinafter, representative embodiments of the present invention will be described. Such as figure 1As shown, the canister 10 includes a housing 11 . The housing 11 is made of resin, and is composed of a square cylindrical housing main body 12 and a lid 13 that closes the opening end surface of the housing main body 12 . The inside of the casing 11 (casing main body 12 ) is partitioned by the partition wall 12 a into two chambers, the first adsorption chamber 11 a and the second adsorption chamber 11 b. The two chambers 11 a and 11 b communicate with each other through a communication passage 11 c formed between the case main body 12 and the cover body 13 . Thereby, a U-shaped gas flow path is formed that communicates the first adsorption chamber 11a and the second adsorption chamber 11b through the communication passage 11c. In addition, in this embodiment, for the convenience of description, in figure 1 Although the canister 10 is illustrated in the horizontal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com