Improved thin film pneumatic control valve

A pneumatic control valve, an improved technology, applied in the direction of valve lift, valve device, valve details, etc., can solve the problems of valve core not closing properly, pressure difference not easy to be too large, valve and pipe elbow bursting, etc., to avoid swinging , to avoid discouragement, to facilitate the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

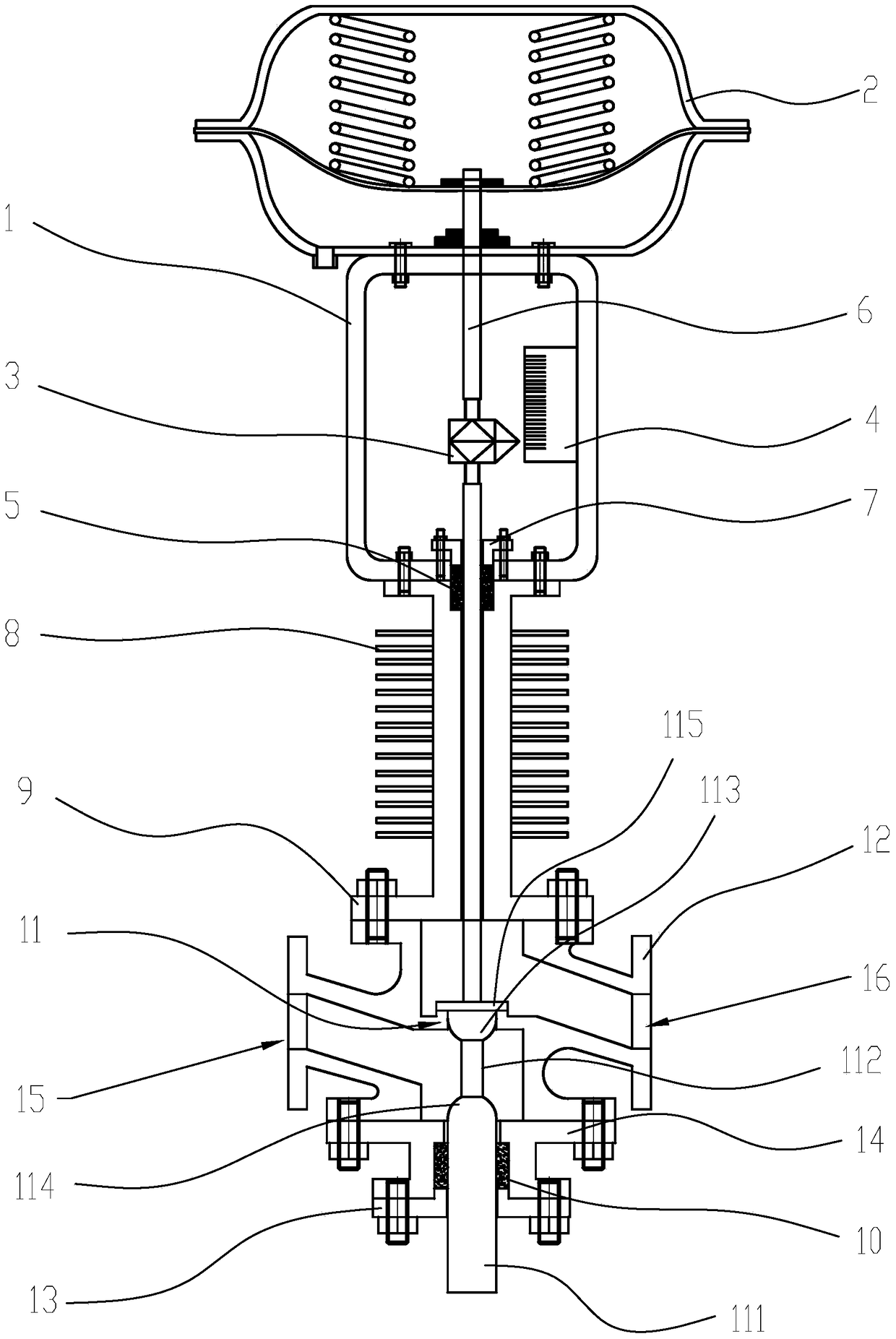

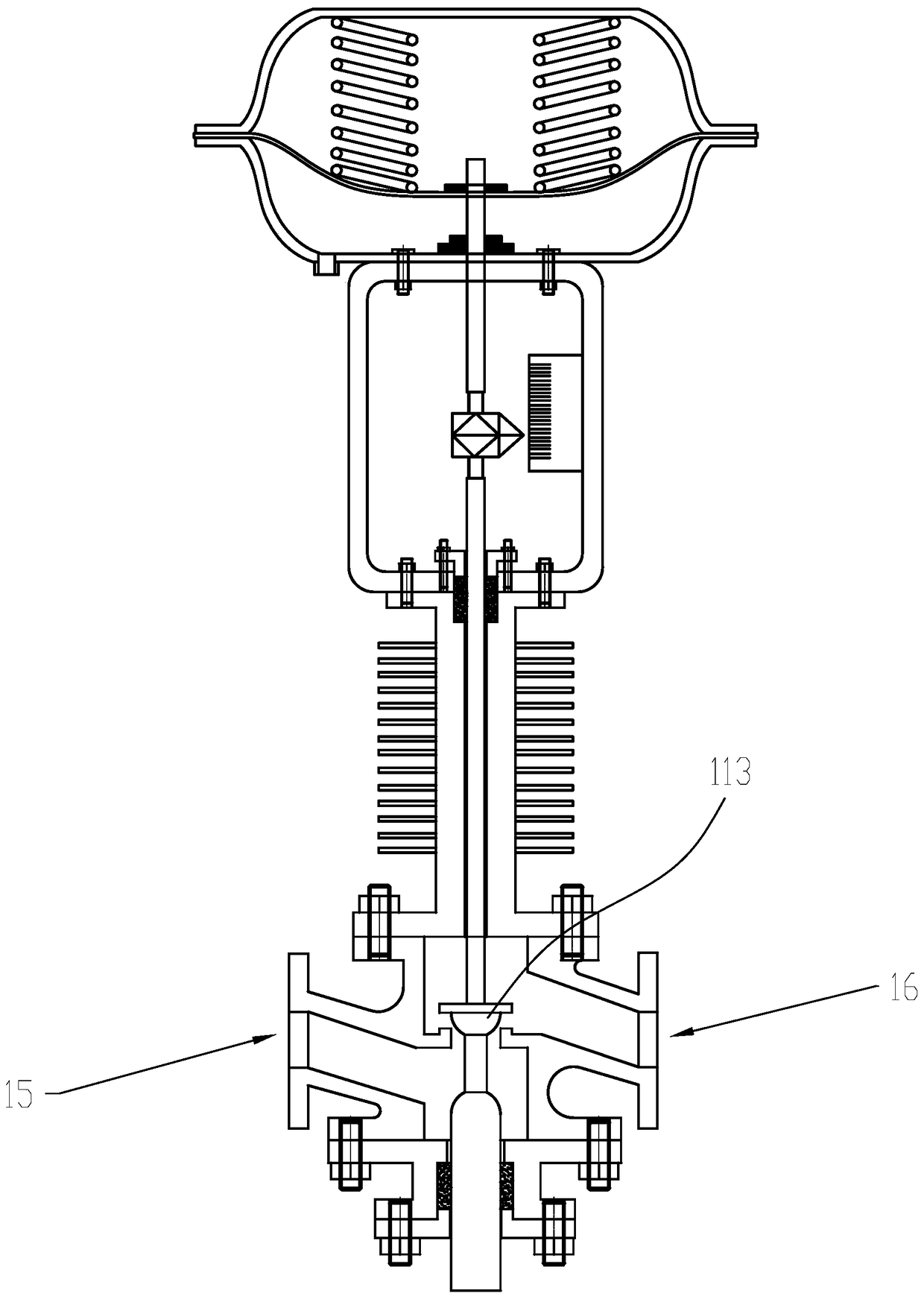

[0019] Embodiment: Improved thin-film pneumatic regulating valve, such as figure 1 As shown, it includes a valve seat 12 with an air inlet 15 and an air outlet 16, an air inlet passage and an air outlet passage arranged in the valve seat, a valve core 11 is arranged at the junction of the air inlet passage and the air outlet passage, The valve core 11 includes a core located at the inlet passage and the outlet passage and a lower valve stem fixed below the core, and the lower valve stem includes a positioning post 111 passing through the valve seat and a valve stem positioned at the valve seat. The connecting rod 112 in the seat, the lower end of the core is a hemispherical upper balance part 113, the upper end of the positioning column 111 is a hemispherical lower balance part 114, the upper balance p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com