High flow pneumatic double solenoid valve for pneumatic amt gearbox

A dual solenoid valve, high flow technology, applied in the field of auto parts, can solve the problems of short service life, small flow rate, low reliability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiment:

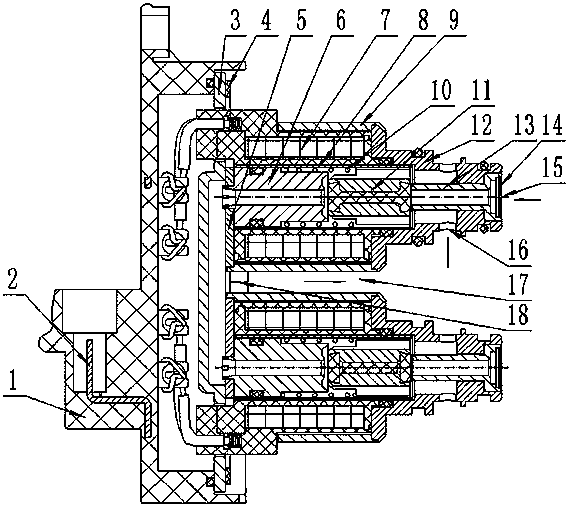

[0026] Such as Figure 1~2 As shown, the large-flow pneumatic double solenoid valve used in the pneumatic AMT gearbox includes a socket assembly and a double valve assembly composed of two single valves; the double valve assembly is mainly a flow path for compressed air.

[0027] The socket assembly is composed of a socket 1 and a pin 2 injected into the socket; the production and assembly process is as follows: first arrange the pins Ⅰ, Ⅱ, and Ⅲ in the socket 1, and then inject molding together with the socket 1, and then Put the sealing ring into the sealing ring slot of the socket 1 to form the socket assembly.

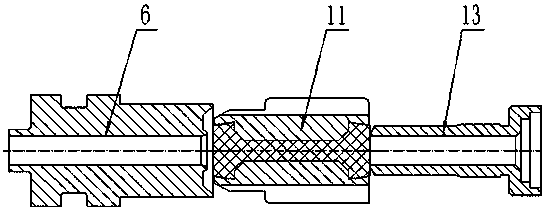

[0028] The single valve includes a valve body 12, a nozzle 13 riveted on one end of the valve body 12, a coil cover 9 fixed to the valve body 12 through a press-fit closing, and a coil assembly 7 located in the coil cover 9, which is arranged in the inner hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com