Online detection method for metal surface microcracks

A metal surface and detection method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high cost of instruments and equipment, inability to implement effectively, complex instruments and equipment, etc., and achieve the effect of low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

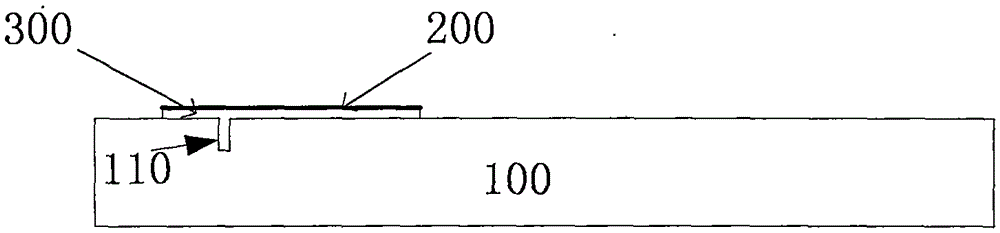

[0013] The present invention proposes a method for on-line detection of micro-cracks on metal surfaces, which includes the following steps: (1), laying at least one layer of microstrip line 200 on the surface of the metal member 100 to be tested; (2), placing the metal member 100 to be tested as Make the grounding layer of the microstrip line 200; (3), connect the microstrip line 200 to the electromagnetic wave transmitting device (not shown); (4), inject electromagnetic waves to the microstrip line 200 through the electromagnetic wave transmitting device; (5), measure The electromagnetic wave reflection of the microstrip line 200 is used as the basis for judging whether there are microcracks 110 on the surface of the metal member 100 to be tested; Microcracks 110 exist in regions corresponding to one or more positions of the microstrip line on the metal member 100 .

[0014] Optionally, one or more layers of microstrip lines may be laid on the surface of the metal component 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com