A full-automatic test equipment for testing finished rubber-sealed circuit boards with nixie tubes

A fully automatic testing and circuit board technology, applied in electronic circuit testing, automatic testing systems, etc., can solve the problems of the difference in the shape and size of the sealed circuit board, the low cost of the photoelectric detection scheme, and the high mechanical precision requirements, so as to improve the processing efficiency and yield, reduce the difficulty of mechanical processing, and reduce the effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

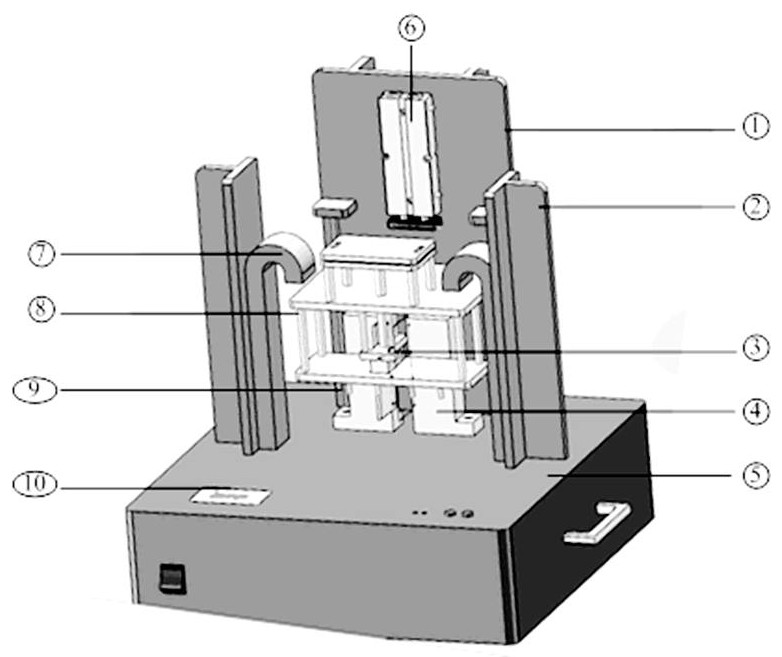

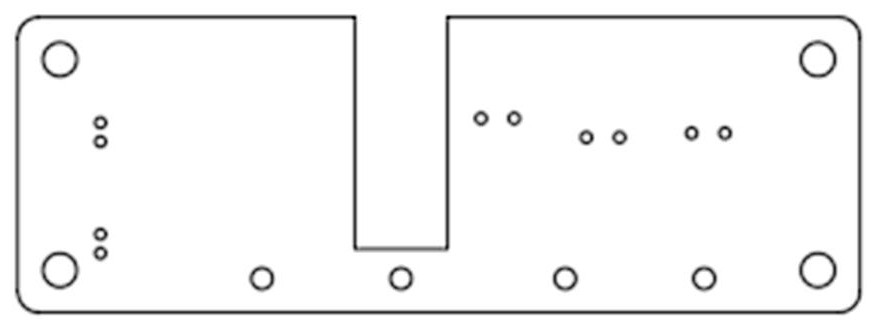

[0058] Such as Figure 1 to Figure 22 As shown, a fully automatic testing device for testing a finished sealed circuit board with a digital tube, including a base 5, a display screen 10 is arranged above the base 5, and a supporting backboard 1 is installed at the rear of the base 5 , the front of the support backplane 1 is equipped with a press-down execution cylinder 6, and the front end of the press-down execution cylinder 6 is equipped with an error correction module, and the error correction module includes a vertical error correction part 3 and a horizontal error correction part 4, The outside of the error correction module is equipped with a press-down actuator 8, and the bottom of the press-down actuator 8 is equipped with an analog button execution cylinder 9, and left and right drag chains 7 are installed on both sides of the error correction module. Left and right drag chain backboards 2 are installed on the outside of the drag chain 7 .

[0059] In this embodiment...

Embodiment 2

[0075] like Figure 1 to Figure 15 , Figure 17 , Figure 19 to Figure 22 , Figure 24 and Figure 25 As shown, a fully automatic testing device for testing finished rubber-sealed circuit boards with digital tubes, including a base 5, a display screen 10 is arranged above the base 5, and a supporting backboard 1 is installed at the rear of the base 5 , the front of the support backplane 1 is equipped with a press-down execution cylinder 6, and the front end of the press-down execution cylinder 6 is equipped with an error correction module, and the error correction module includes a vertical error correction part 3 and a horizontal error correction part 4, The outside of the error correction module is equipped with a press-down actuator 8, and the bottom of the press-down actuator 8 is equipped with an analog button execution cylinder 9, and left and right drag chains 7 are installed on both sides of the error correction module. Left and right drag chain backboards 2 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com