Pressure loss detection method of heat collection pipe network

A detection method and heat collecting tube technology, applied in the direction of instruments, adaptive control, control/regulation system, etc., can solve the problem of inability to accurately test and obtain the pressure loss data of the infinite pipe network of photothermal power generation, poor system control stability, and large effect deviation Major problems, to achieve the effect of ensuring control stability, improving accuracy, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

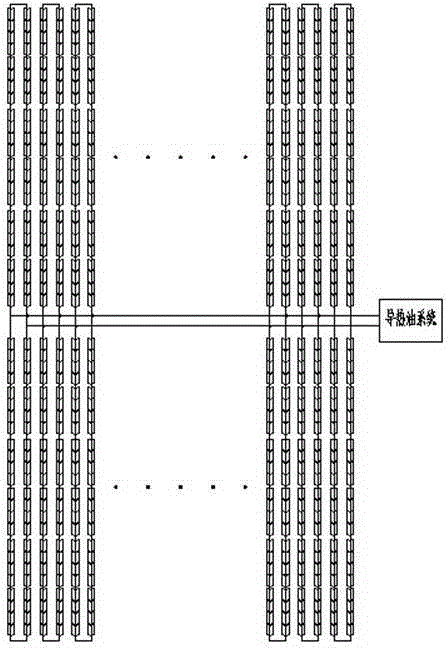

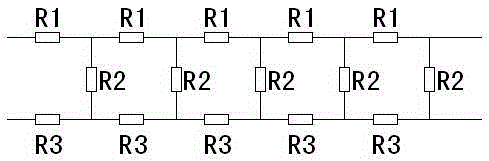

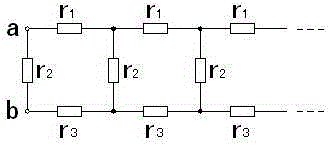

[0042] see Figure 1-Figure 3 , a method for detecting pressure loss of a heat collecting pipe network, comprising the following steps:

[0043] A. Simplify the pipe network of the collector field of the solar thermal power generation system and equivalent it into a resistance network;

[0044] B. The resistance factors of the two solar heat collection circuits on the main pipe in the heat collection field pipe network are equivalent to R2, and the resistance factors along the pipeline between the two branches on the cold oil main pipe and the hot oil main pipe are respectively For R1 and R3, infinite pipeline loops form an infinite network;

[0045] C. Calculate the pressure drop along the pipeline, and calculate the frictional resistance factor of each pipeline, and obtain the resistance value in the resistance network;

[0046] D. According to the equivalent resistance value in the resistance network, the pressure loss value of the heat collection pipe network in the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com