A control method of switched reluctance drive system for pumping unit

A switched reluctance drive and control method technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of increased cost, complex and changeable operating conditions of pumping units, and inability to detect switching points, etc., to ensure Stability, the effect of improving the energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

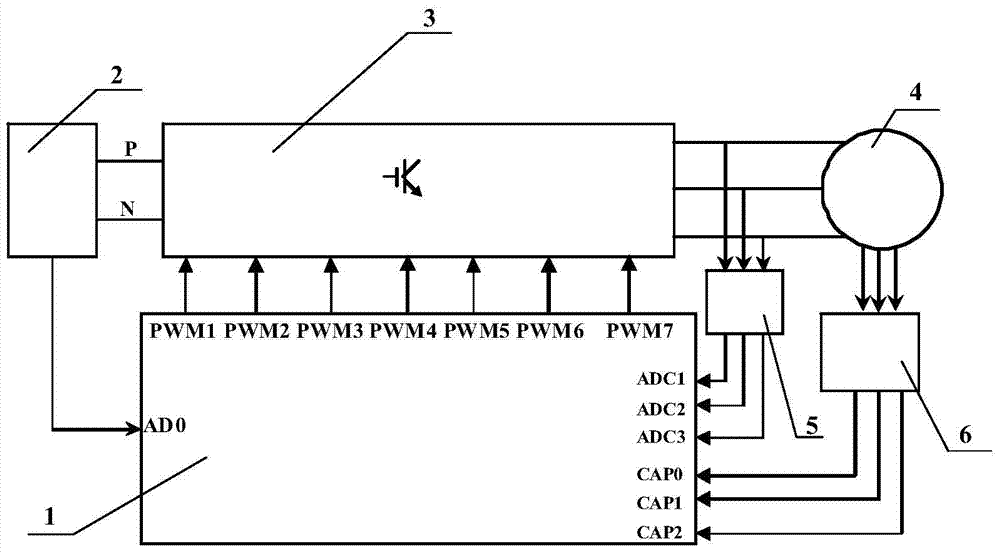

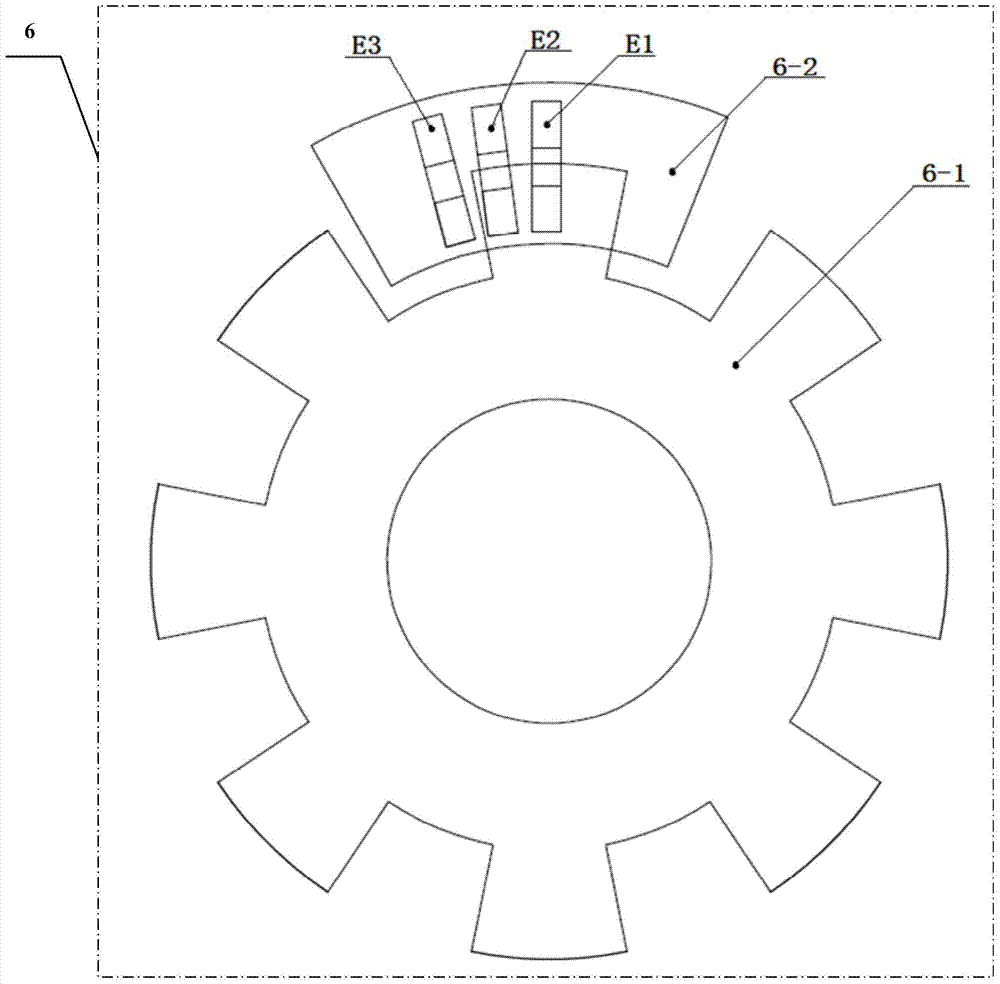

[0035] The specific embodiment of the present invention is as figure 1 As shown, the microcontroller 1 is a 16-bit single-chip microcomputer DSPIC33FJ128MC706, the three-phase rectification and filtering circuit and its bus voltage detection circuit 2 detect the DC bus voltage U of the power converter 3 dc, and input it to the ADC0 port of microcontroller 1. The switched reluctance motor 4 is a three-phase switched reluctance motor with 12 / 8 poles, the rated power is 11kW, and the rated speed is 750r / min. It is powered by the power converter 3 and its three-phase winding is detected by the current detection circuit 5 The current is input to the ADC1 port, ADC2 port and ADC3 port of microcontroller 1 respectively. The three detection elements E1 , E2 , E3 in the position sensor 6 are separated by 7.5° in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com