High efficiency printing system for improved image quality

A high-efficiency, high-efficiency printing head technology, applied in printing devices, printing, color measurement devices, etc., can solve the problems of time-wasting materials and auxiliary equipment, and achieve the effect of reducing environmental impact and prolonging energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

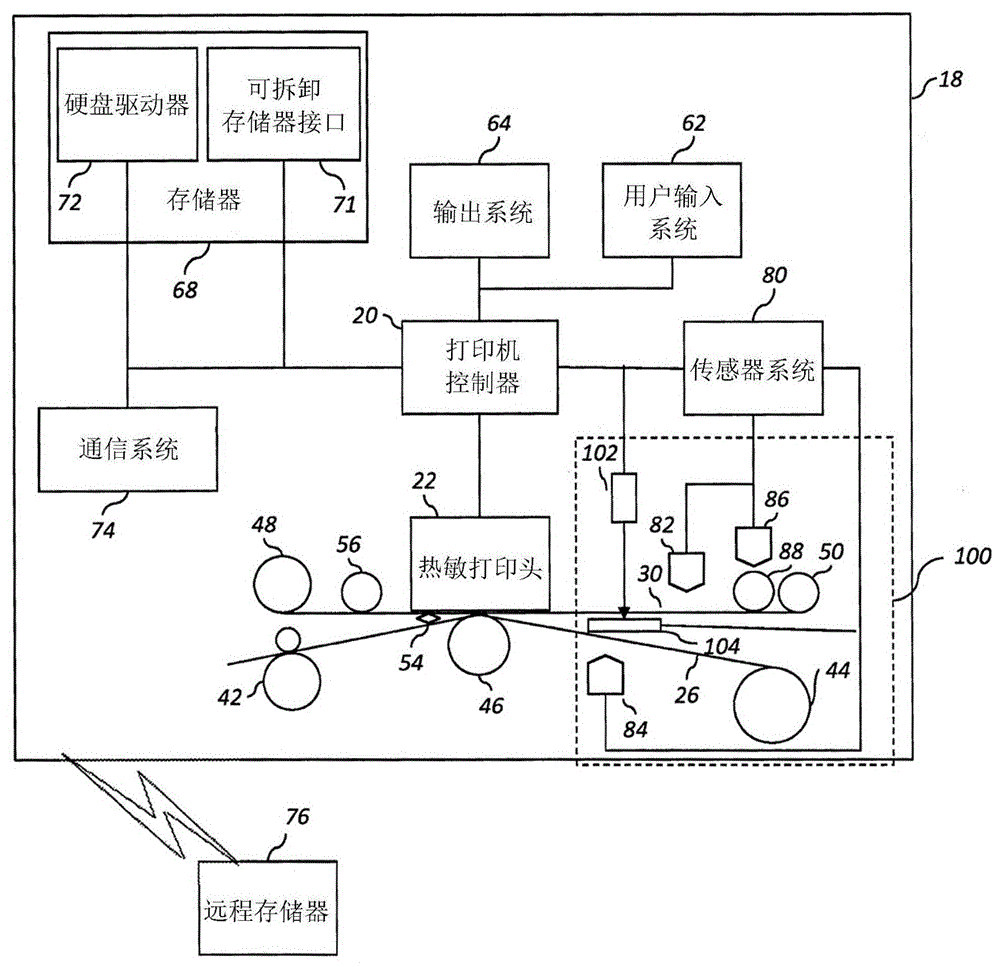

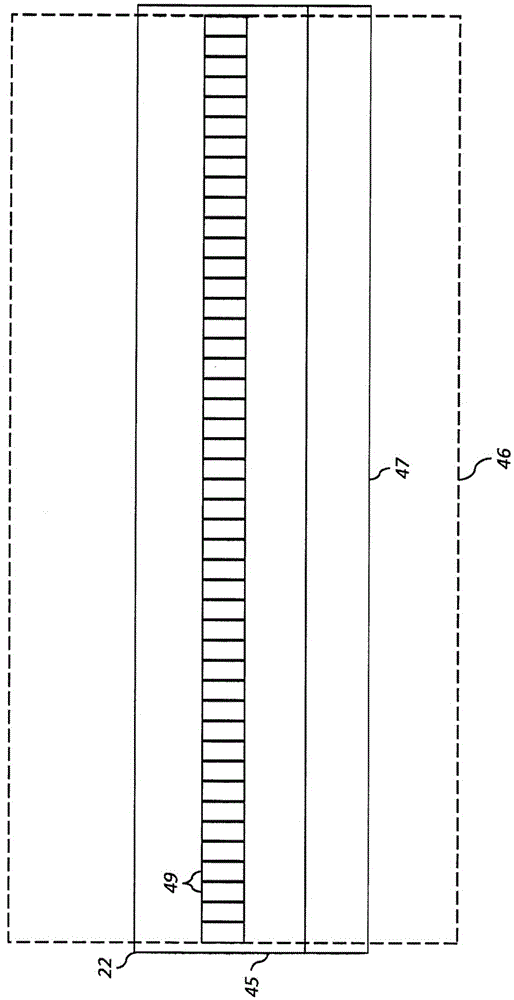

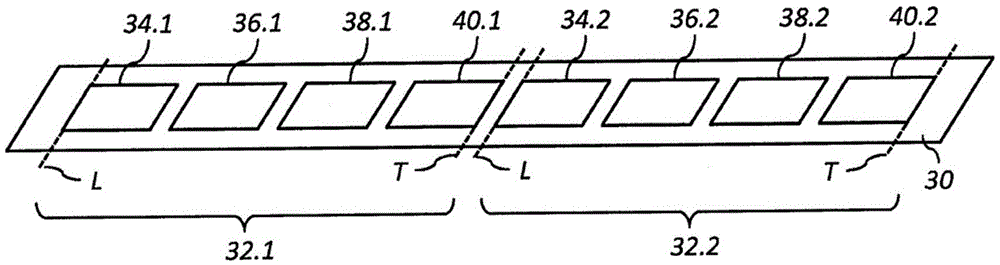

[0026] figure 1 A system diagram of an exemplary thermal printer 18 according to the present invention is shown. Such as figure 1 As shown in , a thermal printer 18 has a printer controller 20 that causes a thermal printhead 22 to record an image onto a receiver medium 26 by applying heat and pressure to transfer material from a donor ribbon 30 to the receiver medium 26 . Receiving medium 26 comprises a dye-receiving layer coated on a substrate. As used herein, the term "receiving medium" is synonymous with the terms "thermographic receiver" and "thermosensitive medium". Similarly, the term "donor ribbon" is synonymous with the terms "thermally sensitive donor" and "donor tape".

[0027] Printer controller 20 may comprise, but is not limited to, a programmable digital computer, a programmable microprocessor, a programmable logic controller, a series of electronic circuits, a series of electronic circuits reduced to an integrated circuit, or a series of discrete components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com