Method for cutting lacquer tree to obtain lacquer

A technology of cutting lacquer and lacquer opening, which is applied in the field of lacquer cutting of lacquer trees. It can solve the problems of slow recovery and growth of lacquer trees, low lacquer production, and large damage to lacquer trees, and achieve the effects of fast wound healing, good results, and increased raw lacquer production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

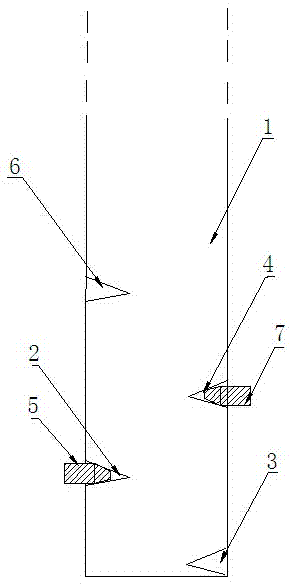

[0014] Example 1 (eg figure 1 shown)

[0015] 1. In the first year, a first paint port 2 is opened on the trunk 1 of the adult lacquer tree 78 cm above the ground, and the pulp is taken;

[0016] 2. In the second year, make a paint nail 5 at the first paint hole 2, and cut two second paint holes alternately with the first paint hole 2 on the opposite side of the trunk 1, and a second paint hole 4 on top At 78cm, a second paint opening 3 is at 78cm below;

[0017] 3. In the third year, make a paint nail 7 at the second paint hole 4, and open the third paint hole 6 at 156 cm directly above the first paint hole 2;

[0018] 4. Follow the law of one-two-one and so on with the continuous growth of the tree every year after that, the first lacquer mouth 2 has healed in the third year;

[0019] 5. The lacquered nails are cut from tough solid wood, and its production method is: split the wood into 12cm long, 2.8cm wide, and 2.3cm thick rectangular wooden strips, put the wooden strip...

Embodiment 2

[0021] 1. In the first year, the first lacquer opening is opened on the trunk of the adult lacquer tree at a distance of 85 cm from the ground, and the pulp is taken;

[0022] 2. In the second year, make a paint nail at the first paint hole, and cut two second paint holes on the opposite side of the trunk and the first paint hole, one at 85cm above and one at 85cm below;

[0023] 3. In the third year, make a paint nail at the second paint opening, and open the third paint opening at 170cm directly above the first paint opening;

[0024] 4. In the following years, as the tree continues to grow, follow the law of one, two, and so on. In the third year, the first lacquer hole has healed;

[0025] 5. the lacquered nails are cut from tough solid wood, and its production method is: split the wood into 12.5cm long, 3.2cm wide, and 2.7cm thick rectangular wooden strips, put the wooden strips on the attic to dry in the shade, and One-third of the wooden strips can be cut into a trapez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com