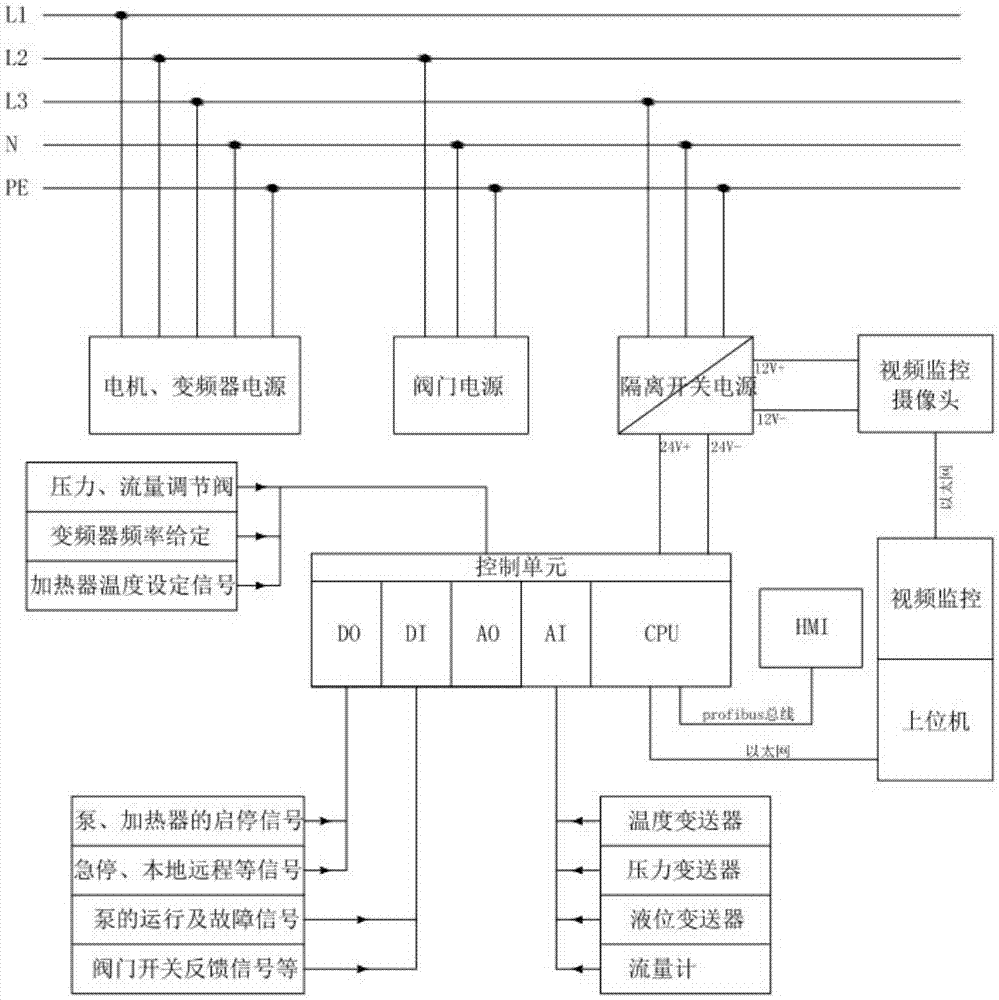

SCWO (supercritical water oxidation) reaction control system

A reaction control system, supercritical water oxidation technology, applied in the control/regulation process, oxidized water/sewage treatment, chemical instruments and methods, etc., can solve the lack of data collection, storage, analysis, large-scale supercritical water oxidation reaction system To solve the problems of slow industrialization and industrialization, to achieve the effect of optimizing work efficiency and avoiding instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

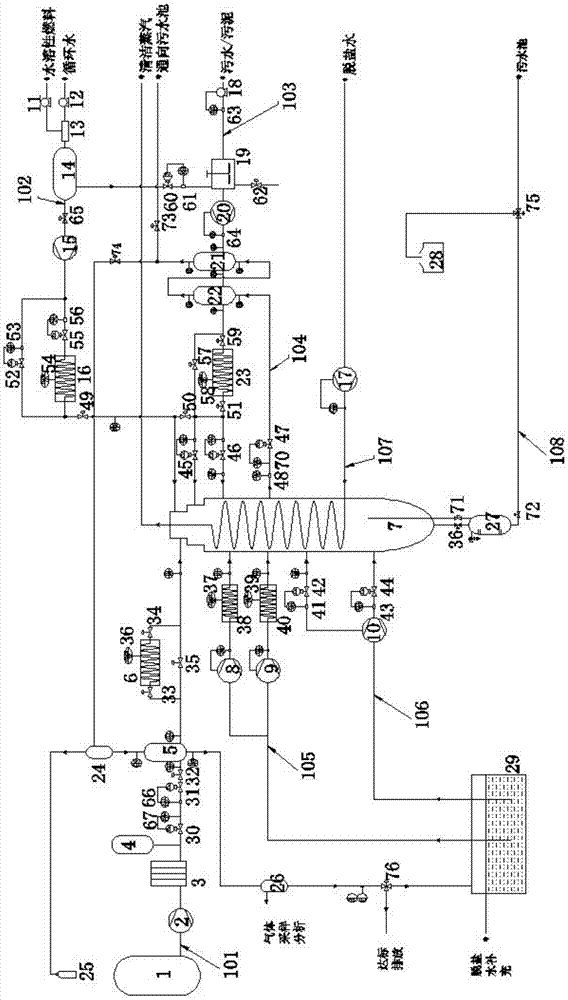

[0057] A supercritical water oxidation reaction control system, including an oxidant delivery pipeline 101, a fuel delivery pipeline 102, a material delivery pipeline 103, a reactor 7, a gaseous product discharge unit, a liquid product discharge unit and a control unit, and an oxidant delivery pipeline The output end of the reactor is connected to the oxidant inlet of the reactor; the output end of the fuel delivery pipeline is connected to the fuel inlet of the reactor; the output end of the material delivery pipeline is connected to the material inlet of the reactor; the gaseous product discharge unit includes a gas phase outlet connected to the reactor The gaseous products exit line 104 .

[0058] Among them, the oxidant delivery pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com