An overall thickening equipment for heavy drill pipe end

A drill pipe and integral technology, which is applied in the field of overall thickening equipment for heavy drill pipe ends, can solve the problems of large equipment investment, metal fiber cutting, and low material utilization rate, so as to reduce equipment investment and increase yield , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

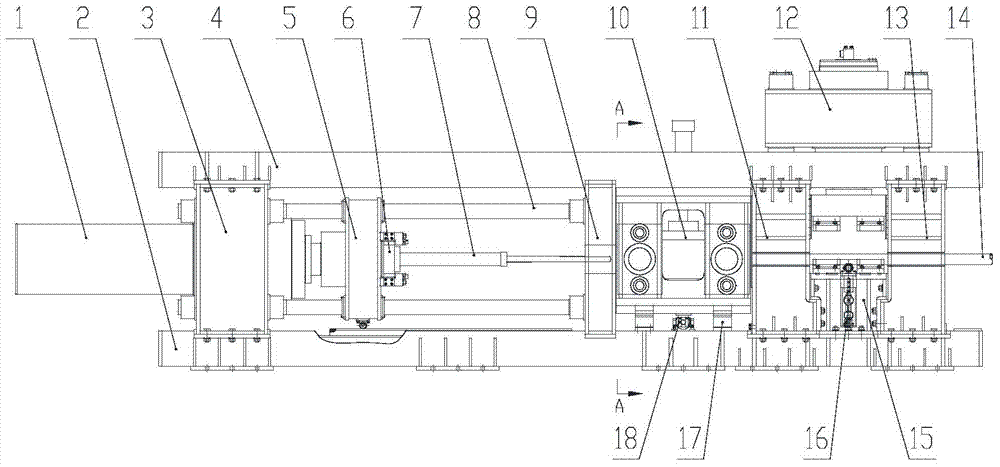

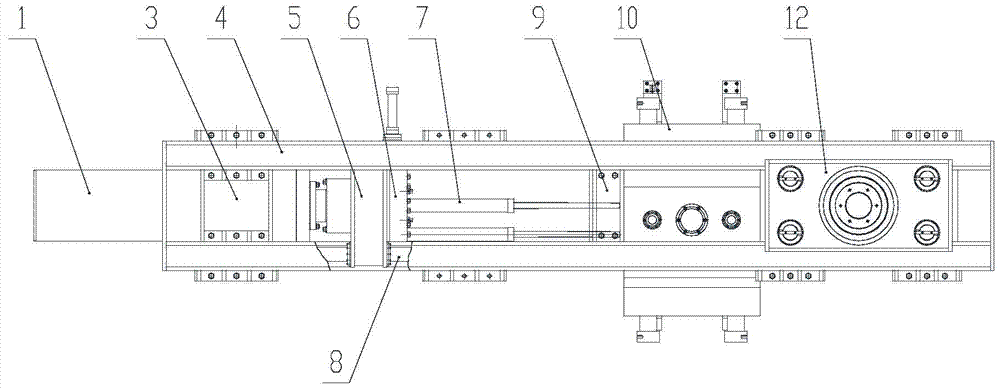

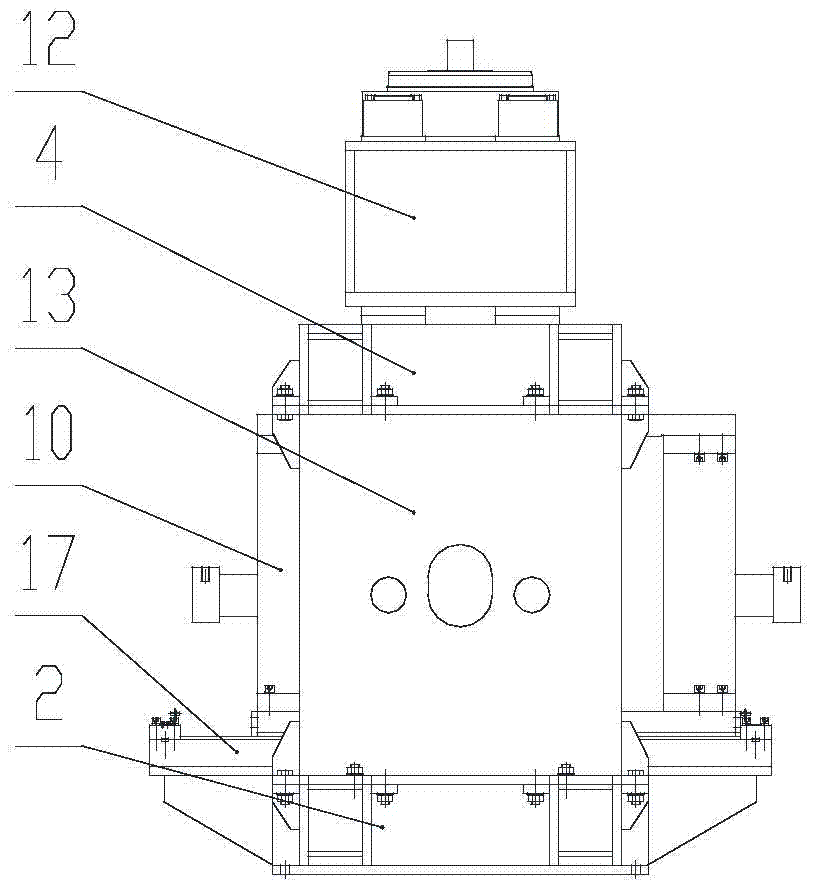

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an overall thickening device for the pipe end of a heavy drill pipe includes a base 2, a base 2, a rear beam 3, a top beam 4, an intermediate beam 9, a rear front beam 11 and a front beam 13 are connected into a frame by connecting pieces, upsetting The rough oil cylinder 1 is connected to the back beam 3, and a guide rod 8 is installed between the back beam 3 and the middle beam 9. The upsetting movable beam 5 is set on the guide rod 8, and one side of the upsetting movable beam 5 is connected with the upsetting oil cylinder 1. The piston rod is connected, and a punch moving device 6 is installed on the other side. A punch 7 is installed on the punch moving device 6. A thickening device 10 is arranged between the middle beam 9 and the rear and front beams 11. The thickening dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com