Point welding machine capable of achieving precise positioning

A technology of precise positioning and spot welding, which is applied to welding equipment, resistance welding equipment, resistance electrode holders, etc., can solve problems affecting product quality, cumbersome operation, low work efficiency and welding accuracy, and achieve work efficiency and High welding precision, simplified operation steps and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

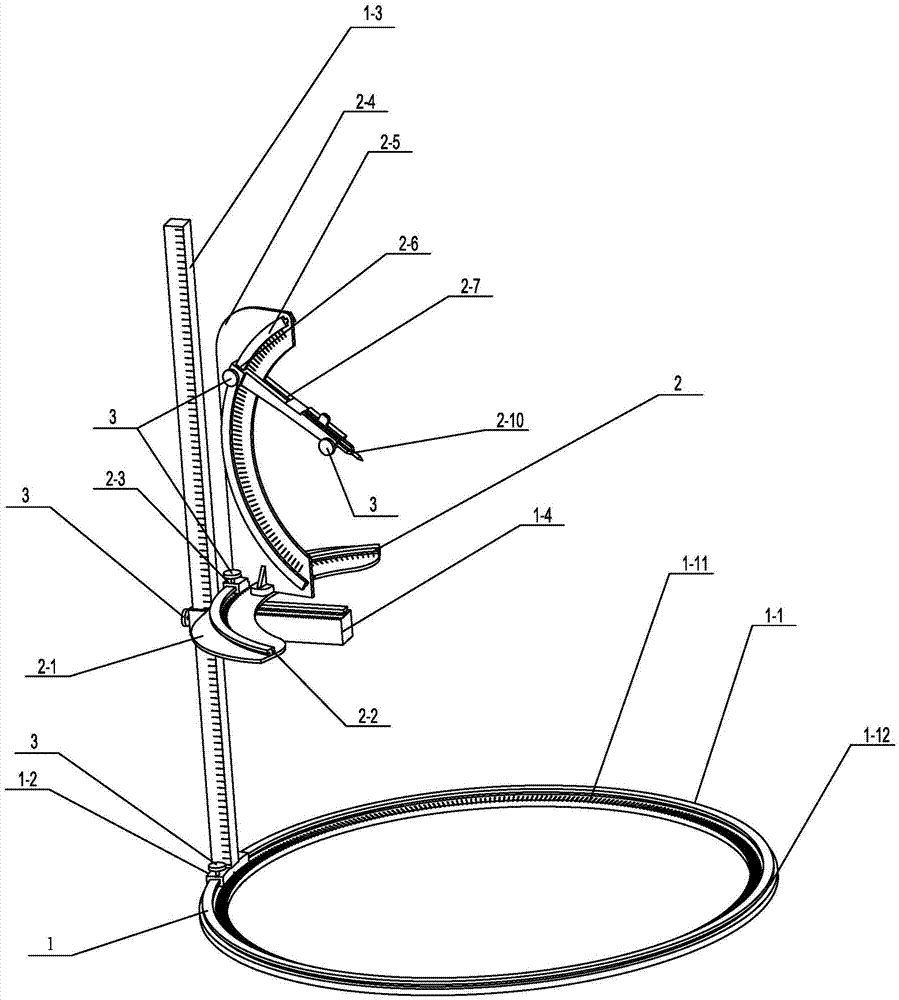

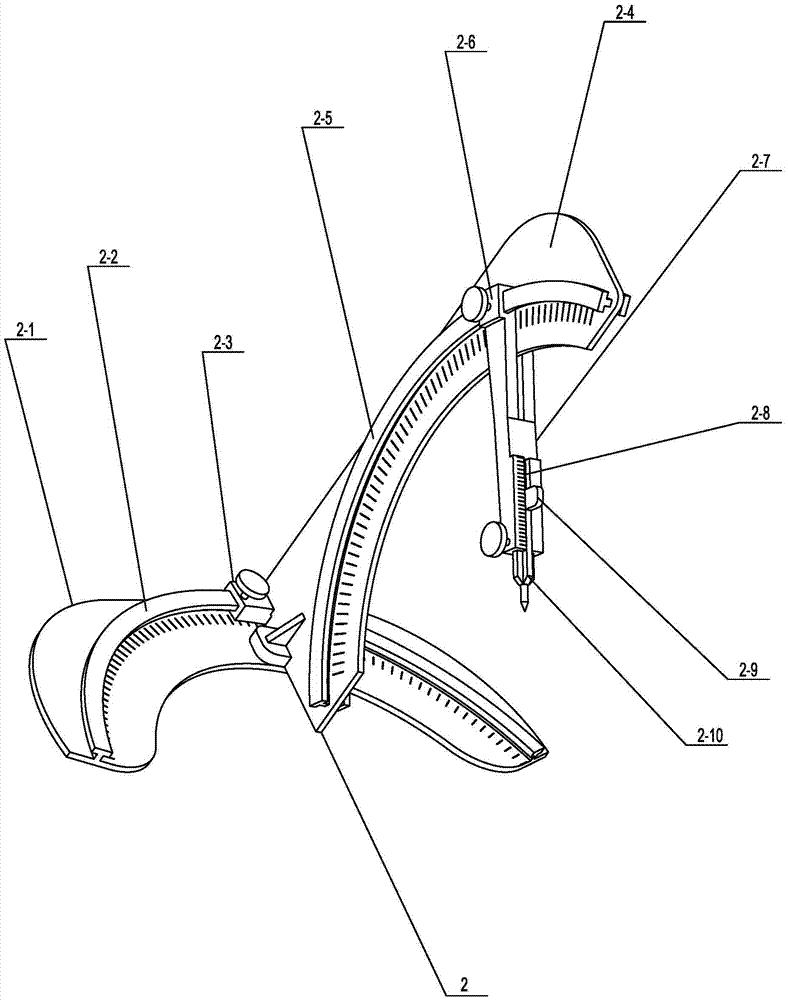

[0019] Such as figure 1 and figure 2 Propose a kind of specific embodiment of the present invention as shown, a kind of spot welder that can accurately locate, comprise cylindrical coordinate device 1, Euler angle positioning device 2, described cylindrical coordinate device 1 comprises disc base 1-1, described The outer side of the disc base 1-1 is provided with a circular slide rail 1-12, and the inner side is engraved with an angle plate 1-11, and the circular slide rail 1-12 is provided with an arc slider 1-2 matched with it. , the arc slider 1-2 is provided with a Z-axis scale rod 1-3 engraved with a scale, and the Z-axis scale rod 1-3 is provided with a linear slide rail 1-4, and the linear slide rail 1-4 can slide along the Z-axis scale bar 1-3 and is arranged perpendicular to the Z-axis scale bar 1-3. 4 sliding linear slider; the Euler angle positioning device 2 includes a precession angle positioning mechanism and a nutation angle positioning mechanism, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com