A compound machine for chamfering and rolling cutting of ring parts

A compound machine and ring-shaped technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low processing efficiency, high input cost, and inconvenient operation, so as to improve work efficiency, reduce processing equipment, and fix the effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

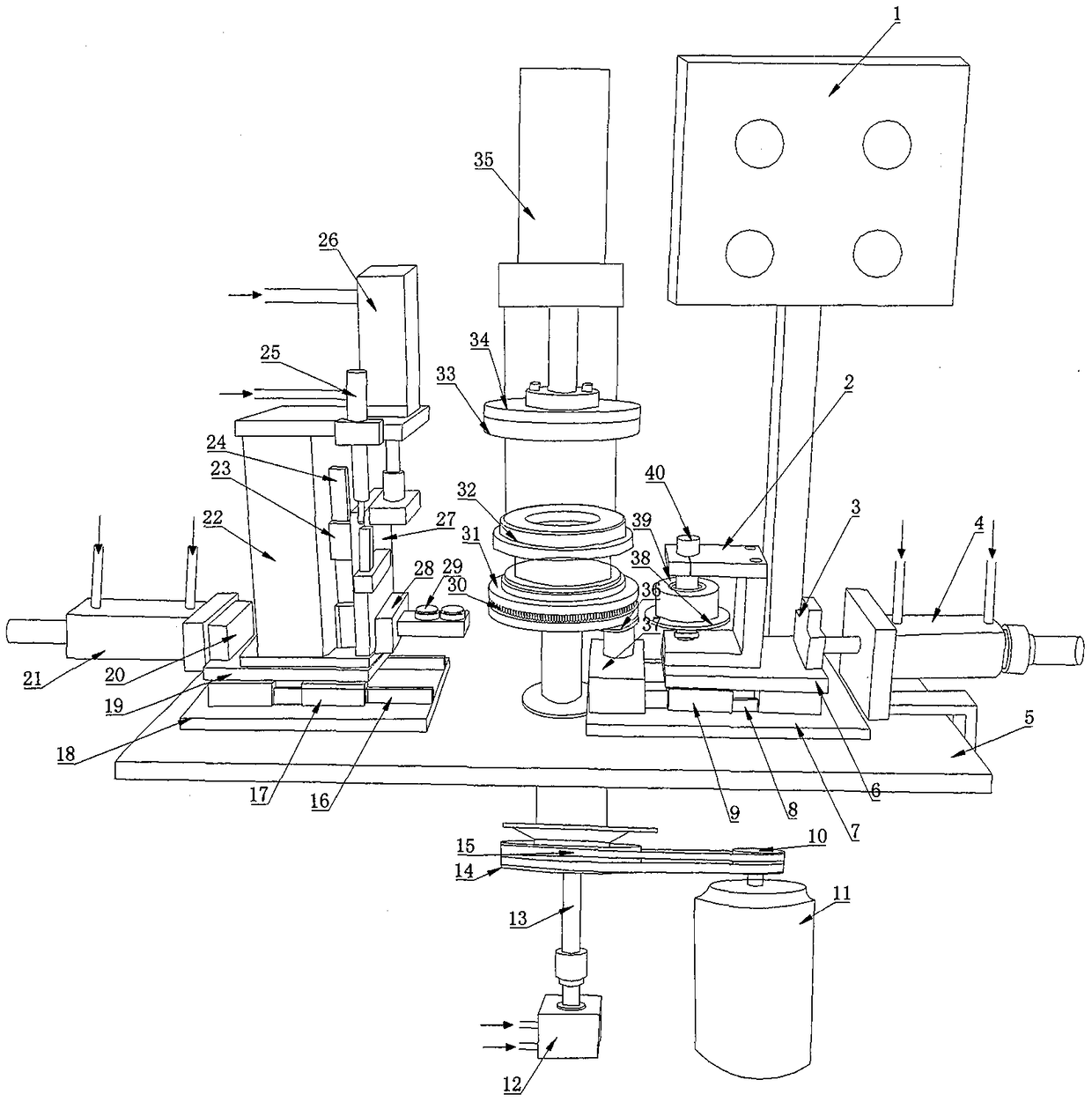

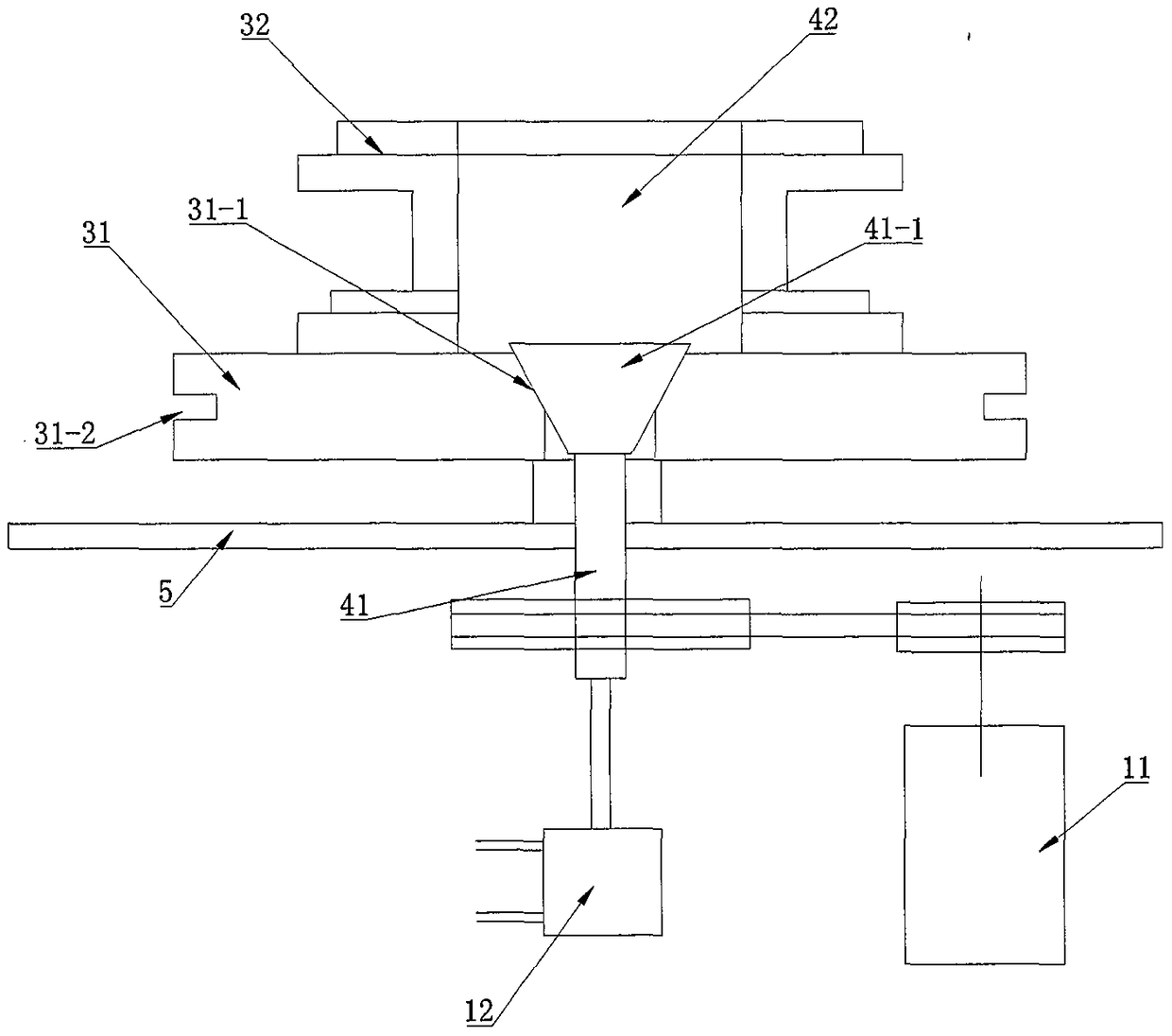

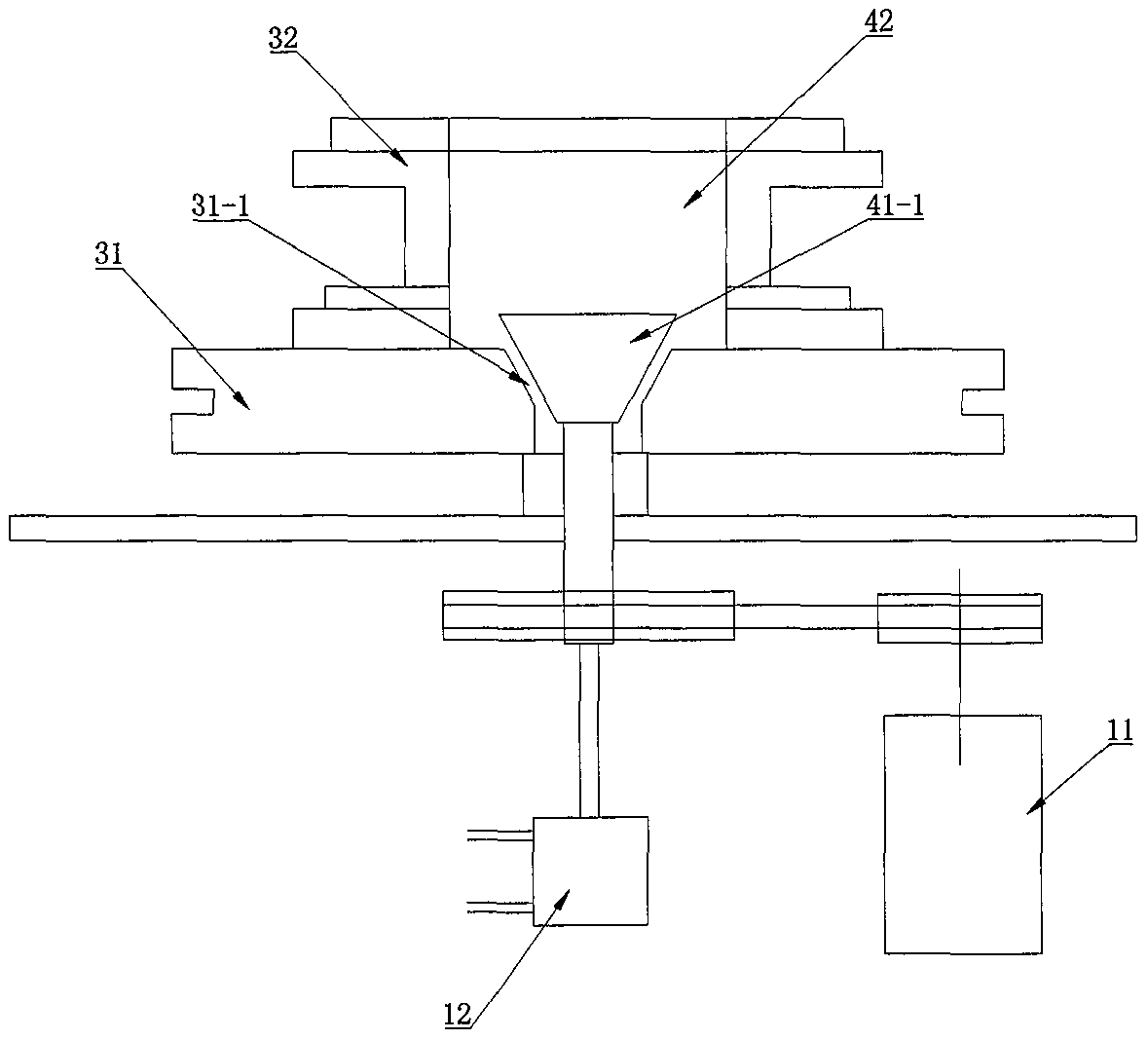

[0022] Such as figure 1 and figure 2 Shown, the present invention comprises workbench 5, control panel 1 and the hemming mechanism that is installed on the workbench successively from left to right, main power mechanism and trimming mechanism. The control panel 1 is electrically connected with the main power mechanism, the trimming mechanism and the hemming mechanism respectively. The control panel 1 is used to control the orderly work of the main power mechanism, the trimming mechanism and the hemming mechanism.

[0023] The active power mechanism includes a power source, an installation platform connected with the power source and installed on the workbench, and a pressing component located above the installation platform. The power source includes a motor 11 , a driving wheel 10 , a driven wheel 14 , a second cylinder 12 and a transmission shaft 41 . One end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com