Egg cake intelligent processing equipment

A technology of intelligent processing and omelet, which is applied in the direction of baking pancakes, oil/fat baking, etc., and can solve the problems of unsatisfactory mixing effect of fabric and egg liquid, poor quality of omelette, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

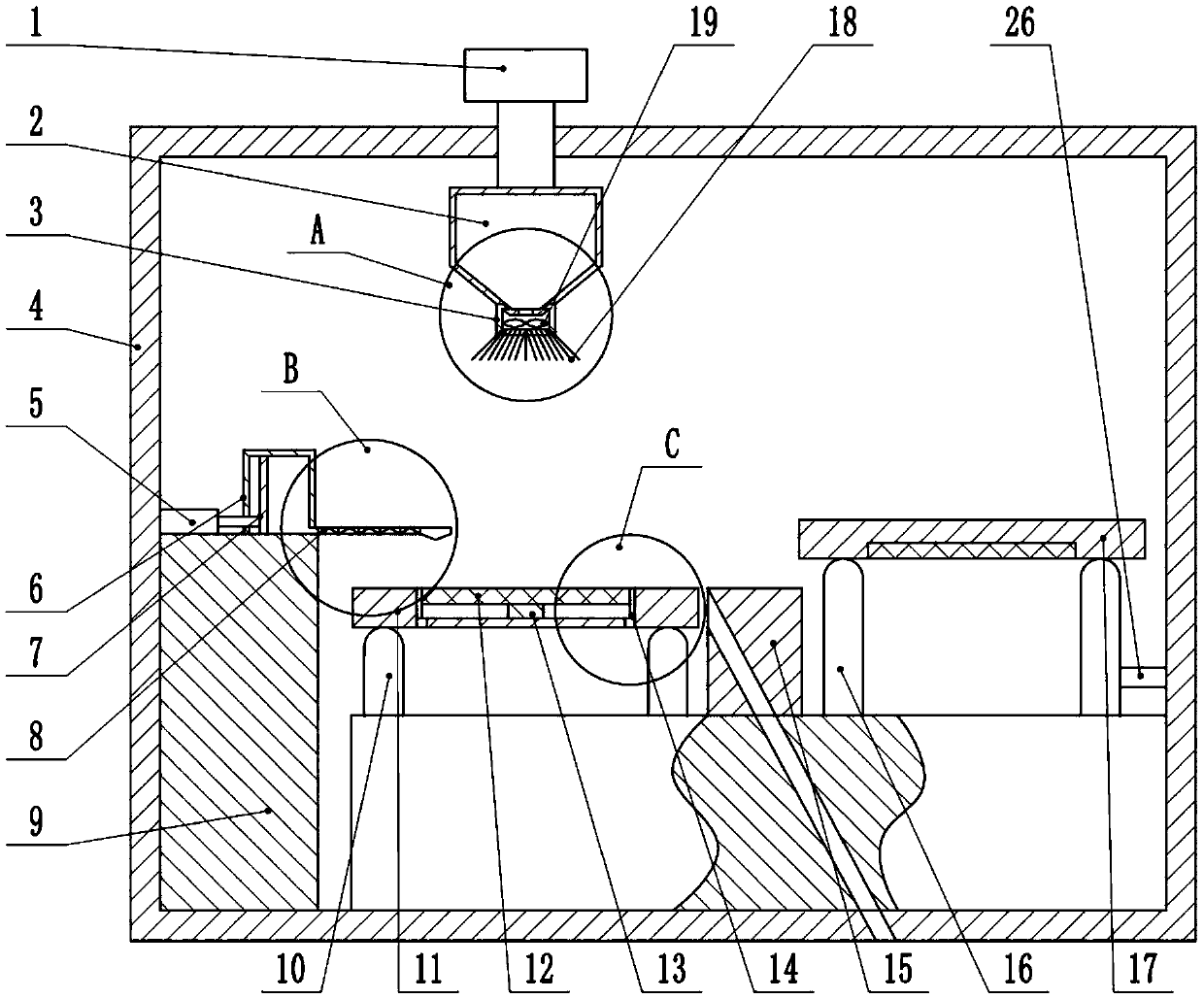

[0046] Embodiment one is basically as attached figure 1 Shown: an intelligent processing equipment for egg cakes, including a processing chamber 4, a processing table, a feeding mechanism, a heating mechanism, a discharging mechanism and a stirring mechanism, the heating mechanism includes a first heating mechanism and a second heating mechanism, and the processing table is located in the processing room 4 and is at the bottom of the processing chamber 4, the left and right side walls of the processing table are offset against the left and right side walls of the processing chamber 4;

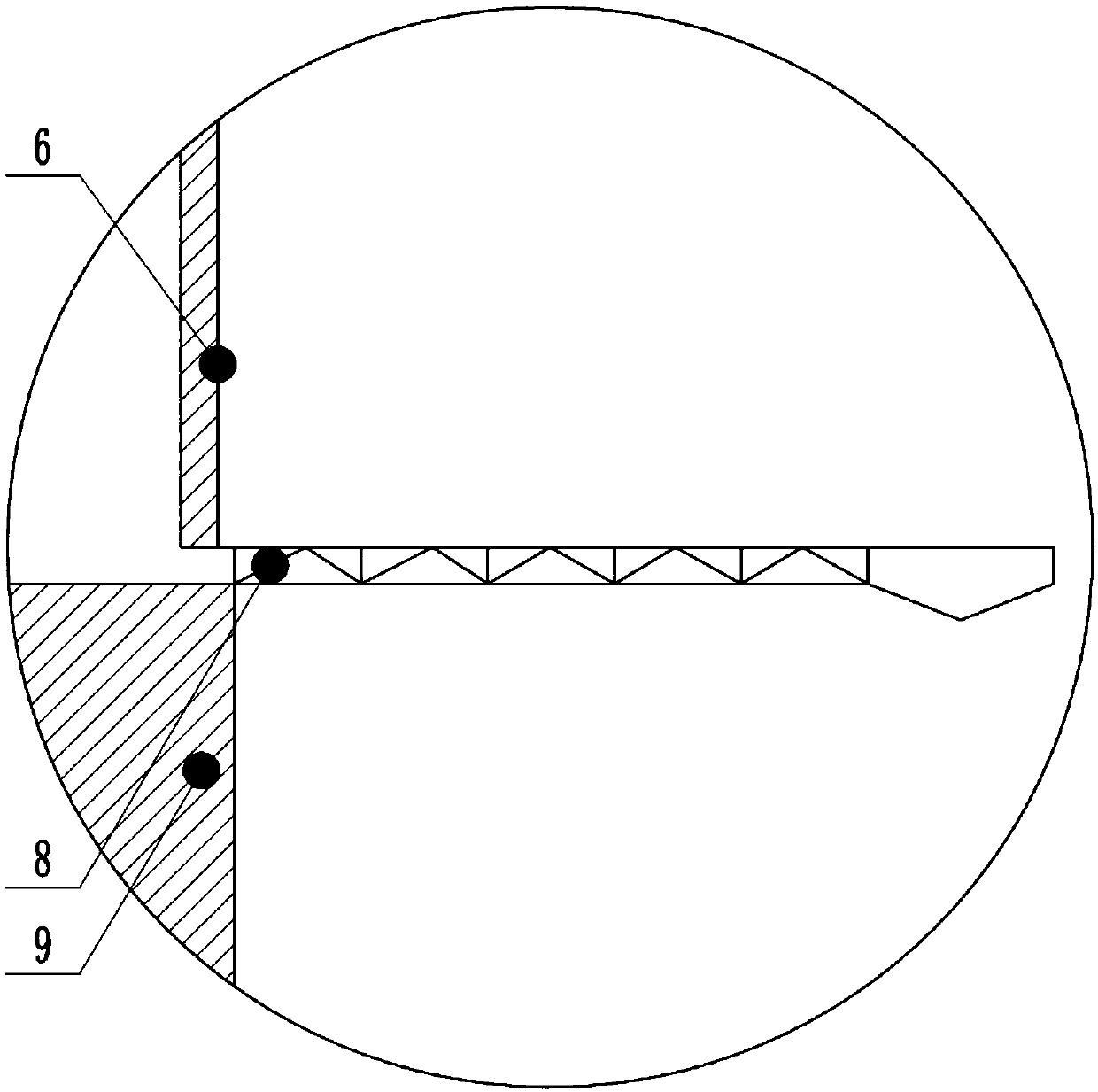

[0047] The feeding mechanism is located on the left side of the processing table and is close to the left side wall of the processing chamber 4. The feeding mechanism includes an electric push rod 5, a material bin 6 and a discharge pipe 8. The left end of the electric push rod 5 is fixed to the left side wall of the processing chamber 4. The right end protrudes into the interior of the silo 6,...

Embodiment 2

[0066] Embodiment two is basically as attached Figure 6 As shown, the difference between embodiment two and embodiment one is:

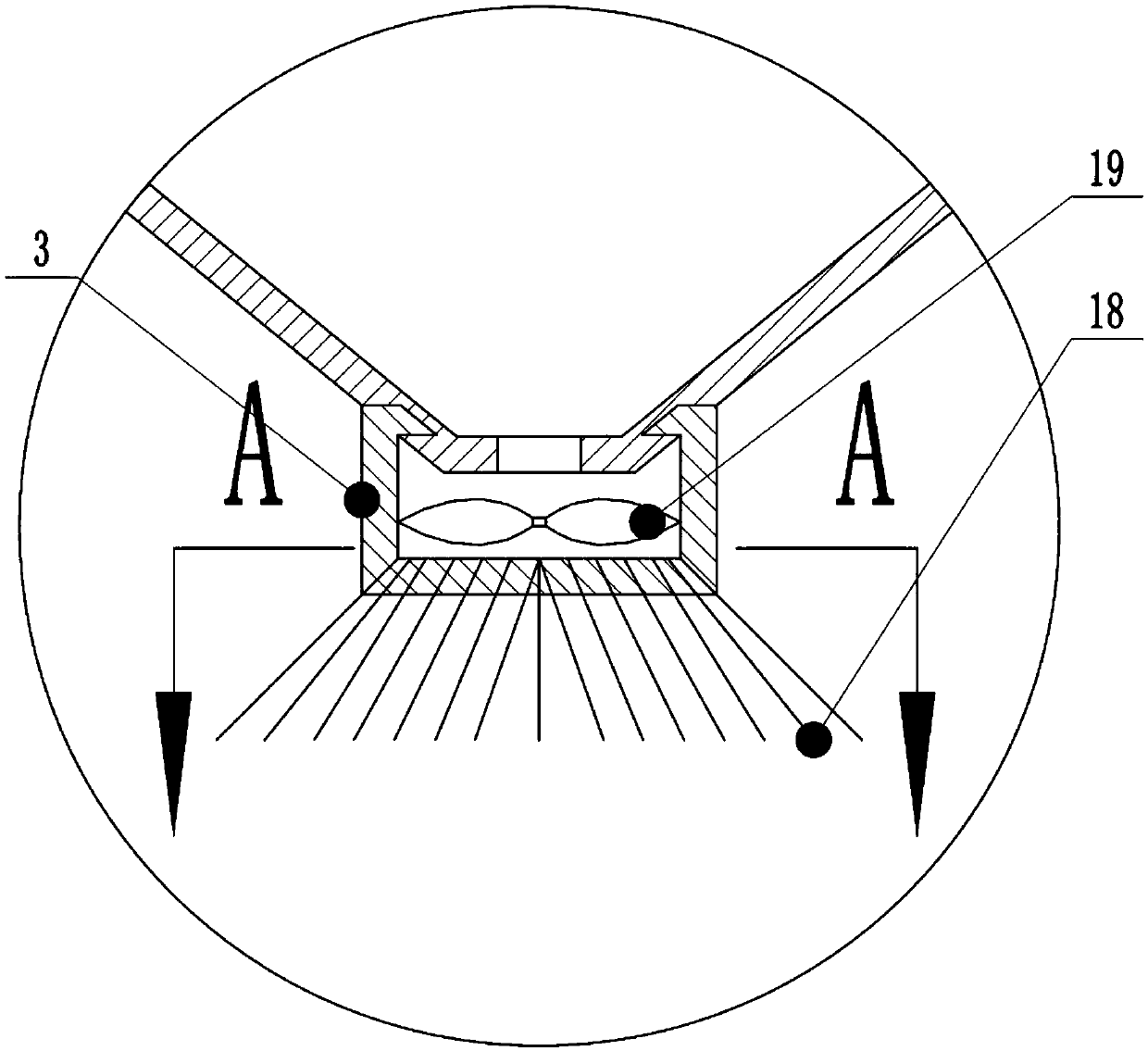

[0067] a. The rotating frame 3 is also fixedly connected with a perforated plate 22 for egg liquid to flow out. The perforated plate 22 divides the rotating frame 3 into two chambers, the first paddle 19 is arranged in the lower chamber, and the upper chamber is provided with The second paddle 20, the first paddle 19 and the second paddle 20 are fixedly connected with the inner wall of the rotating frame 3 (as Figure 7 shown);

[0068] b. The storage room 2 is fixedly provided with a mounting plate, the mounting plate is provided with a through hole for egg liquid to flow out, the bottom of the mounting plate is also provided with a motor 21 with a rotating shaft, and the free end of the motor 21 rotating shaft is fixedly connected with a connecting rod. The rod passes through the storage chamber 2 and is connected to the central axis of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com