Spraying main pipe capable of preventing water accumulation and dust accumulation

An anti-water and anti-dust technology, which is applied in the field of pipelines, can solve the problems of bending and deformation of the spray main pipe, and achieve the effects of increasing the area of the pressure zone, improving the bending stiffness, anti-corrosion and simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

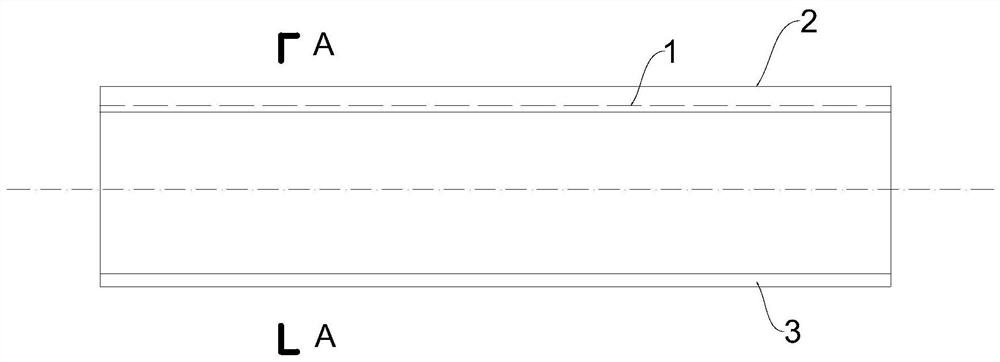

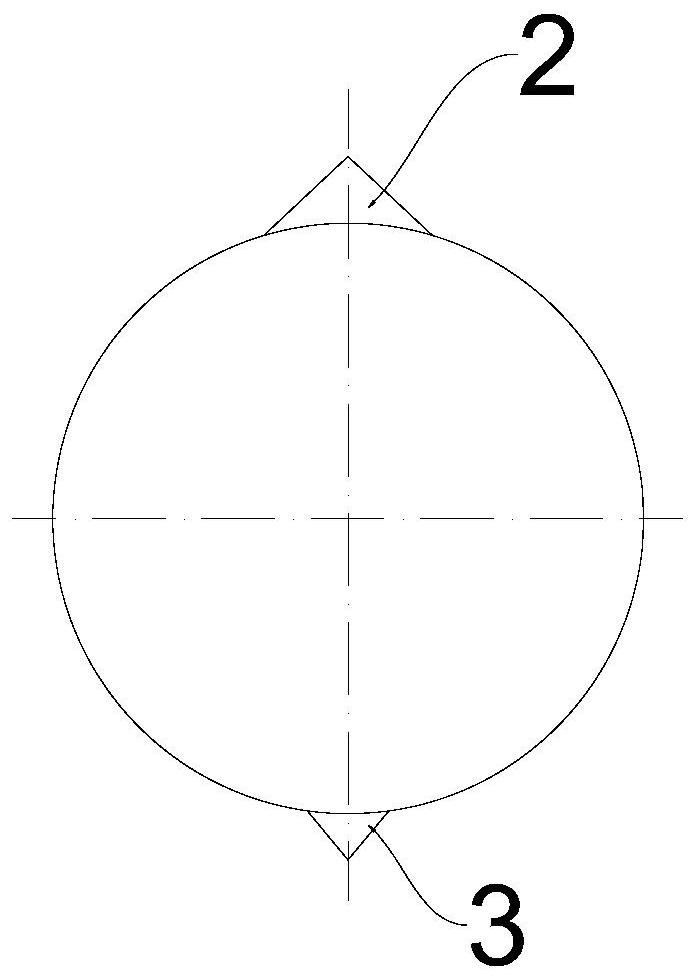

[0038] combine figure 1 , figure 2 As shown, the present embodiment provides an anti-water and dust accumulation sprinkler main pipe, including:

[0039] Ontology 1,

[0040] Anti-deposition part 2, the anti-deposition part 2 is fixedly installed on the top of the body 1, and the anti-deposition part 2 is configured as a triangle; and

[0041] The confluence part 3 is fixedly installed on the bottom of the main body 1, and the confluence part 3 is provided with sharp corners downward along the direction of gravity.

[0042] By setting the anti-deposition part 2 on the top of the body 1, and the anti-deposition part 2 is configured as a triangle, it can effectively prevent dust from accumulating, and at the same time prevent the upper layer of slurry from directly dripping on the top of the body 1, reducing the impact of the slurry on the top of the body 1. of corrosion.

[0043] By setting the confluence part 3 at the bottom of the body 1, and the confluence part 3 is pro...

Embodiment 2

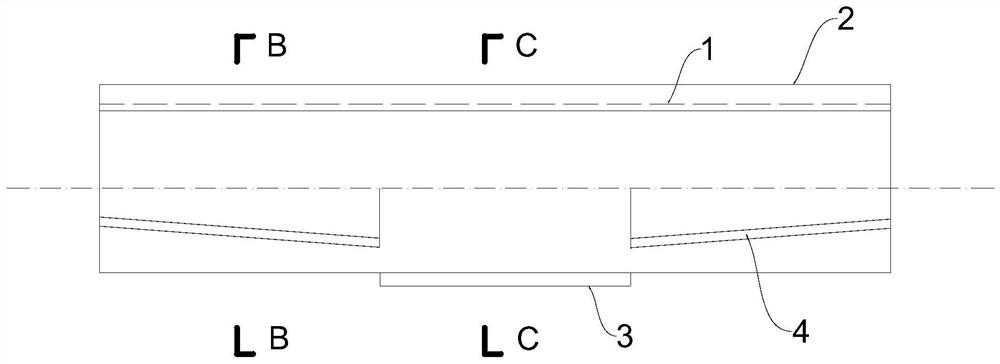

[0058] combine Figure 3-Figure 5 As shown, different from the above-mentioned embodiments, in the anti-water and dust accumulation sprinkler main pipe provided in this embodiment, the size of the confluence part 3 along the length direction is smaller than the size of the body 1 along the length direction, and is arranged at the The middle position of the main body 1 along the length direction.

[0059] Specifically, the anti-water and dust accumulation sprinkler main pipe also includes side wing drainage parts 4, and the side wing drainage parts 4 are arranged below the outer surface of the main body 1 where the diameter along the horizontal direction is the largest.

[0060] Specifically, the side wing drainage portion 4 extends from the end portion of the body 1 in the axial direction to the middle portion, and is inclined downward along the direction of gravity during the extension process.

[0061] Specifically, the side wing drainage portion 4 is at least partially ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com