Multi-channel mandrel machining equipment

A processing equipment, multi-channel technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problem of large channel roughness and roundness, difficult to control and adjust, multi-channel size dispersion and other problems, to achieve the effect of stable processing quality, strong versatility and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

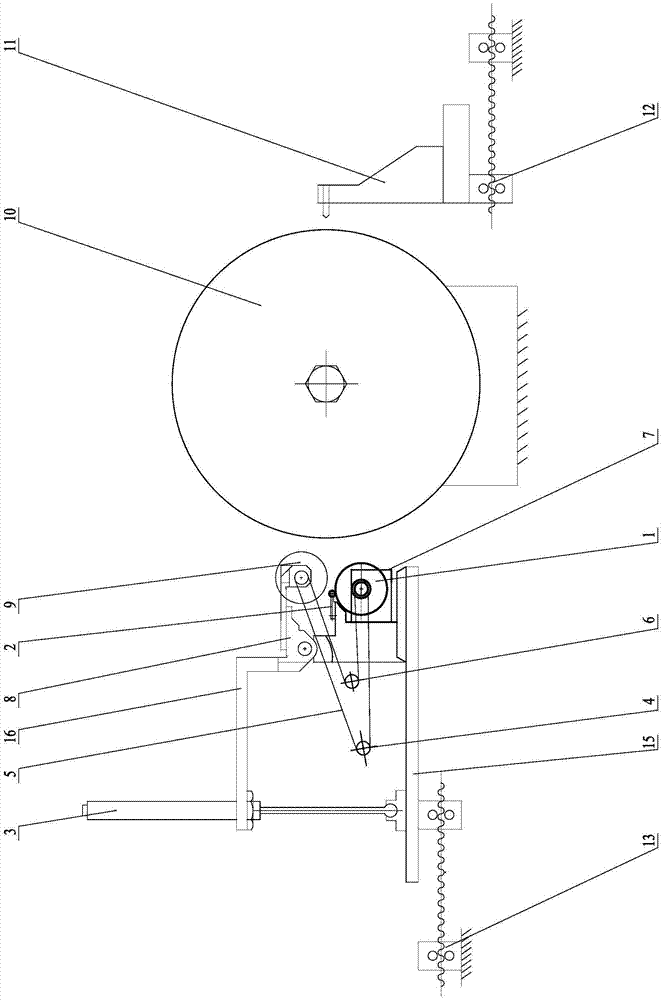

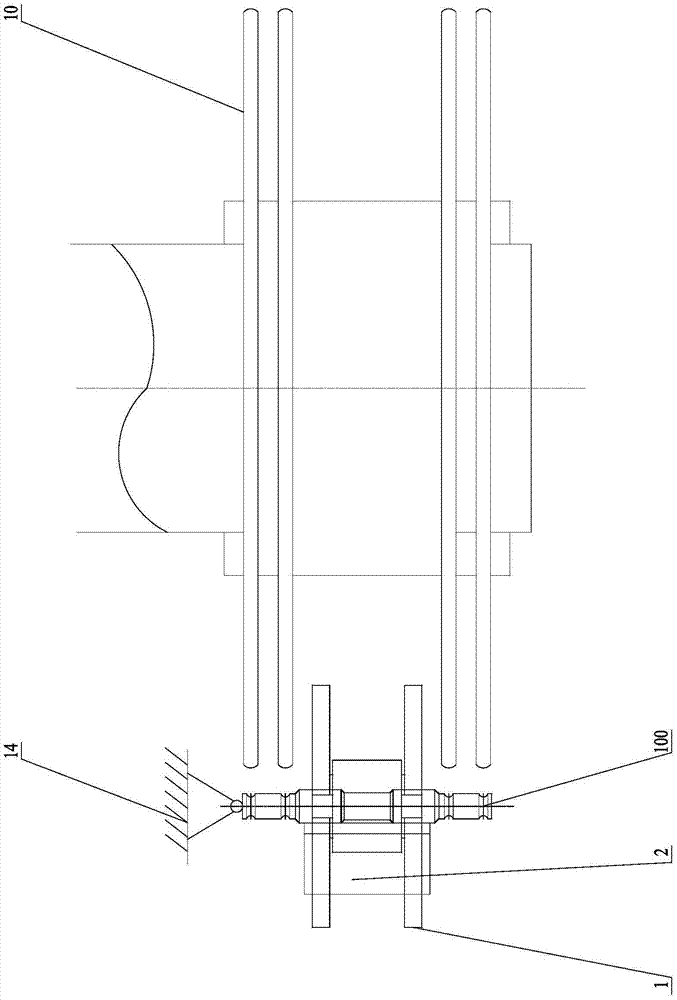

[0014] This multi-channel mandrel processing equipment is equipped with a frame 15 on the first horizontal cross translation base 13, a lower roller seat 7 is fixed on the frame 15, and a rear support 2 is fixed on the lower roller seat 7. The lower roller 1 is rotated on the 7, the upper roller seat 8 is hinged on the lower roller seat 7, the upper roller 9 is installed on the upper roller seat 8, the upper roller 9 and the lower roller 1 are driven by the timing belt 5, and the timing belt 5 Driven by the driving wheel 4, the timing belt 5 is tensioned by the tension wheel 6; a backing 14 is fixed on the frame 15 on the rear side of the upper roller 9 and the lower roller 1, and the machine on the right side of the upper roller 9 and the lower roller 1 Rotate on the frame 15 and be equipped with emery wheel axle, be fixed with emery wheel 10 on emery wheel axle, be provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com