Built-in nails

A self-contained, nail-shooting technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of high labor intensity, high dud rate, hidden safety hazards, etc., to increase the convenience of use, prolong the shelf life, and the explosion speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

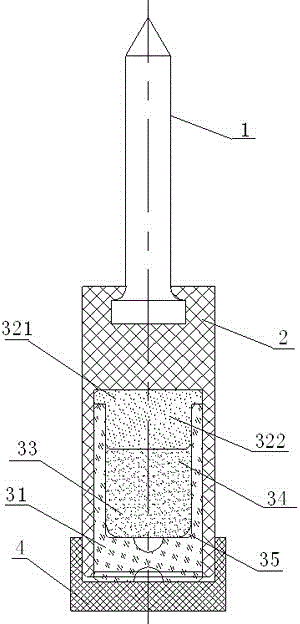

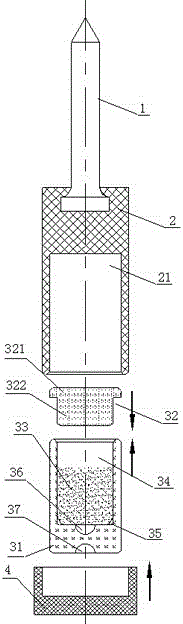

[0020] like Figure 1 to Figure 3 As shown, the self-contained nail can be used, including the nail body 1, the nail bearing housing 2 and the kinetic energy component. One end of the nail bearing housing 2 is provided with a nail cap accommodation cavity, and the nail cap of the nail body 1 is embedded in the nail. Inside the cap accommodating chamber, the other end is provided with a kinetic energy component installation chamber 21 , and the tail of the nail-shooting bearing housing 2 is provided with a safety rear cover 4 .

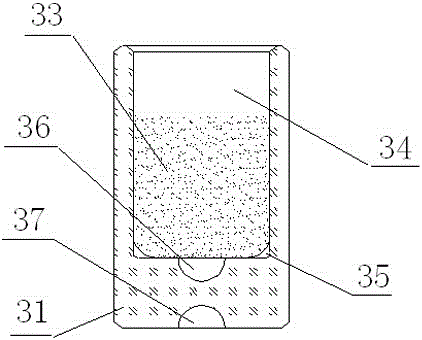

[0021] The kinetic energy assembly includes a kinetic energy mother shell 31 with an inner cavity 34, a T-shaped sealing cover 32, and a kinetic energy agent 33. A primer 36 is placed at the bottom of the kinetic energy mother shell 31, and a kinetic energy agent 33 is placed in the inner cavity 34. The 31 tail of the kinetic energy mother shell is provided with The firing pin guide hole 37, the T-shaped sealing cover 32 and the inner cavity 34 of the ...

Embodiment 2

[0025] like Figure 4 and Figure 5 As shown, in the above-mentioned embodiments, the use of solid primer powder has the disadvantages of complicated process, high requirements, high risk in the production process, and loud explosion sound during use, but when using dry powder primer powder as the primer, the explosion speed is fast and the explosion noise is small , so on the basis of Embodiment 1, the kinetic energy shell (kinetic energy mother shell 31) in the kinetic energy assembly is changed as follows to obtain an improved self-energy nailing: the kinetic energy shell includes an inner cavity with a first cavity 391 The shell 39 and the outer shell 38 with the second cavity 381, the middle of the bottom of the first cavity 391 of the inner shell 39 is provided with a detonation port 392, and the bottom of the second cavity 381 of the shell 38 is for placing the primer 36 (preferably dry powder powder) The arc-shaped groove 382, the tail of the shell 38 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com