Geotextile composite material cutting and sealing system

A geotechnical composite material and cutting machine technology, which is applied in metal processing and other directions, can solve the problems of bentonite shedding and low anti-seepage performance of the membrane at the edge, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

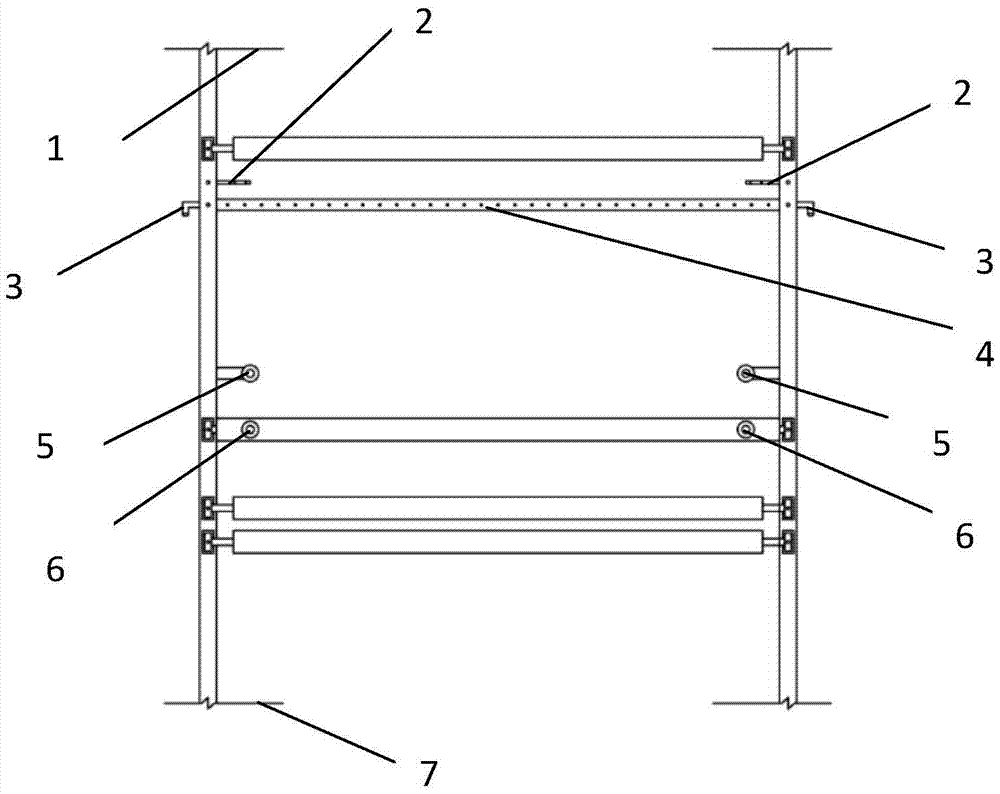

[0014] A cutting edge sealing system for geotechnical composite materials, including a coil cutting machine and a water edge sealing device, the water adding edge sealing device includes a longitudinal water feeder and a horizontal water feeder, and the longitudinal water feeder is fixed along the moving direction of the longitudinal cutter On the frame on both sides of the feeding shaft of the coil cutting machine, the horizontal water feeder is fixed on the frame parallel to the feeding shaft of the coil cutting machine along the moving direction of the horizontal cutter, and the vertical and horizontal water feeders are provided by corresponding Water filling switch control.

[0015] Enter the composite geotechnical material containing bentonite from the inlet of the device, turn on the longitudinal water feeder, the bentonite at the edge of the geomembrane will swell with water, and cut it through the longitudinal cutter device after 30s to complete the longitudinal cutting...

Embodiment 2

[0017] A cutting edge sealing system for geotechnical composite materials, including a coil cutting machine and a water edge sealing device, the water adding edge sealing device includes a longitudinal water feeder and a horizontal water feeder, and the longitudinal water feeder is fixed along the moving direction of the longitudinal cutter On the frame on both sides of the feeding shaft of the coil cutting machine, the horizontal water feeder is fixed on the frame parallel to the feeding shaft of the coil cutting machine along the moving direction of the horizontal cutter, and the vertical and horizontal water feeders are provided by corresponding Water filling switch control.

[0018] Enter the composite geotechnical material containing bentonite from the inlet of the device, turn on the longitudinal water feeder, the bentonite at the edge of the geomembrane will swell with water, and cut it through the longitudinal cutter device after 45 seconds to complete the longitudinal ...

Embodiment 3

[0020] A cutting edge sealing system for geotechnical composite materials, including a coil cutting machine and a water edge sealing device, the water adding edge sealing device includes a longitudinal water feeder and a horizontal water feeder, and the longitudinal water feeder is fixed along the moving direction of the longitudinal cutter On the frame on both sides of the feeding shaft of the coil cutting machine, the horizontal water feeder is fixed on the frame parallel to the feeding shaft of the coil cutting machine along the moving direction of the horizontal cutter, and the vertical and horizontal water feeders are provided by corresponding Water filling switch control.

[0021] Enter the composite geotechnical material containing bentonite from the inlet of the device, turn on the longitudinal water feeder, the bentonite at the edge of the geomembrane will swell with water, and cut through the longitudinal cutter device after 60s to complete the longitudinal cutting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com