Easily-dismounted portal crane and dismounting method thereof

A technology of gantry cranes and slabs, which is applied in the direction of hoisting equipment braking devices, load hanging components, bottom support structures, etc., can solve the problems of cumbersome assembly of components, long time-consuming, self-heavy, etc., and achieve simplified disassembly and Hoisting and assembling process, reduction of working time at heights, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

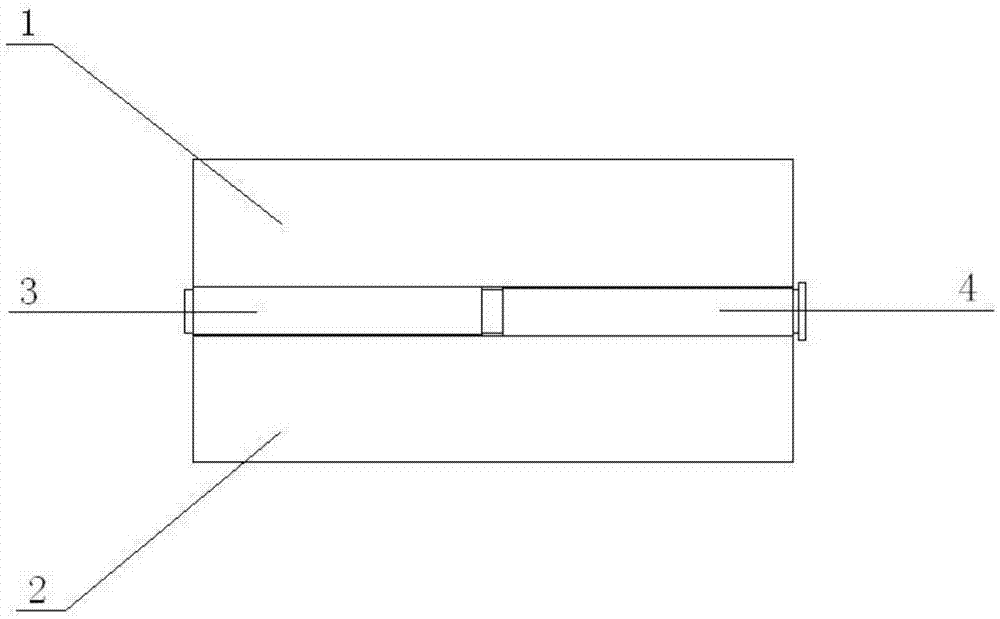

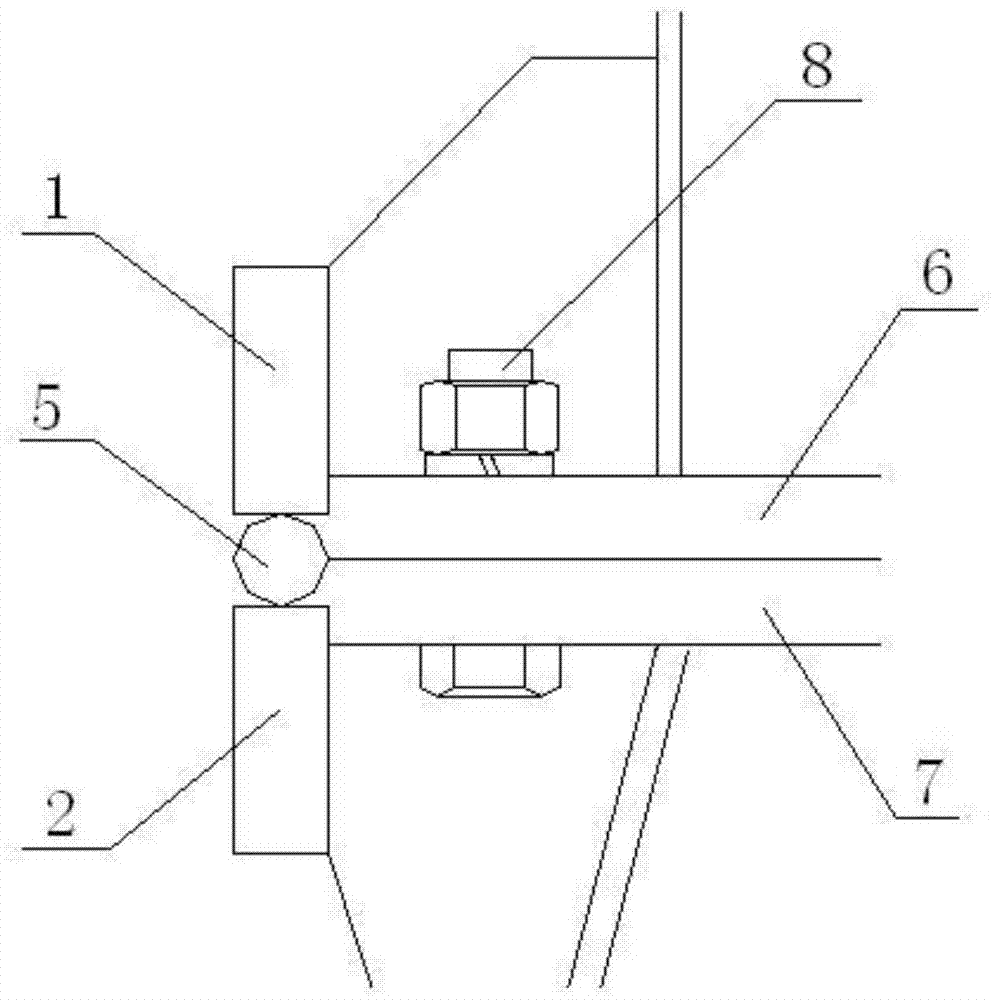

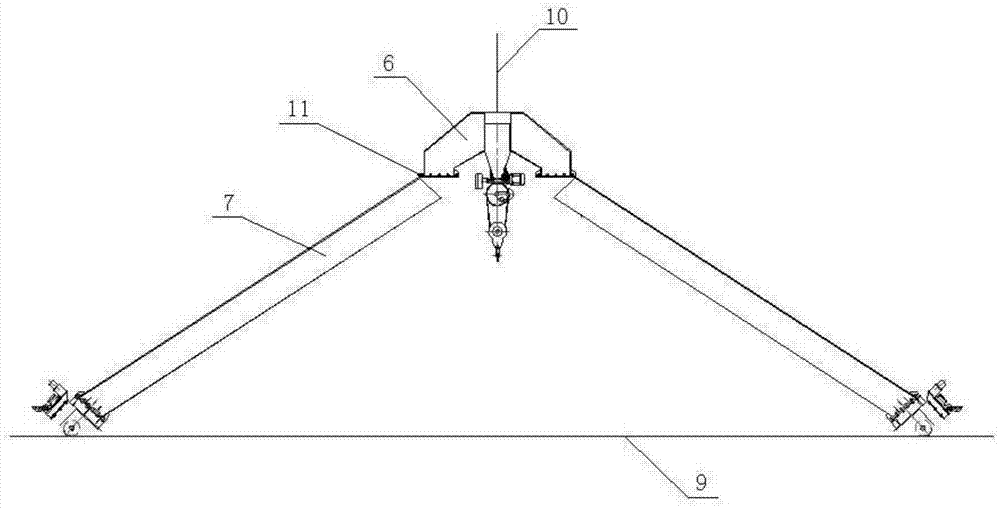

[0022] as attached Figure 1-3 As shown, a gantry crane that is easy to disassemble includes a gantry crane main girder 6 and four gantry crane supports 7 supporting the main girder 6, and an opening and closing device is arranged between the main girder 6 and the supports 7 11. The opening and closing device 11 includes a first page plate arranged on the main beam 6 and located outside the connection with the bracket 7, and arranged on the bracket 7, located outside the connection with the main beam 6 and connected to the first page The second leaf plate 2 corresponding to the plate; the edge of the first leaf plate is provided with a first mandrel 3, and the first mandrel 3 is connected to the first leaf plate by double-sided welding; the first The mandrel 3 is connected with the second mandrel 4 arranged on the edge of the second page 2 and matched with the first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com