Multi-moire-color blended yarn and production device and method thereof

A technology of blended yarn and color, applied in spinning machine, textile and paper making, continuous winding spinning machine, etc., can solve the problems of low spinning efficiency, limited draft ratio, etc., and improve the added value of yarn Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

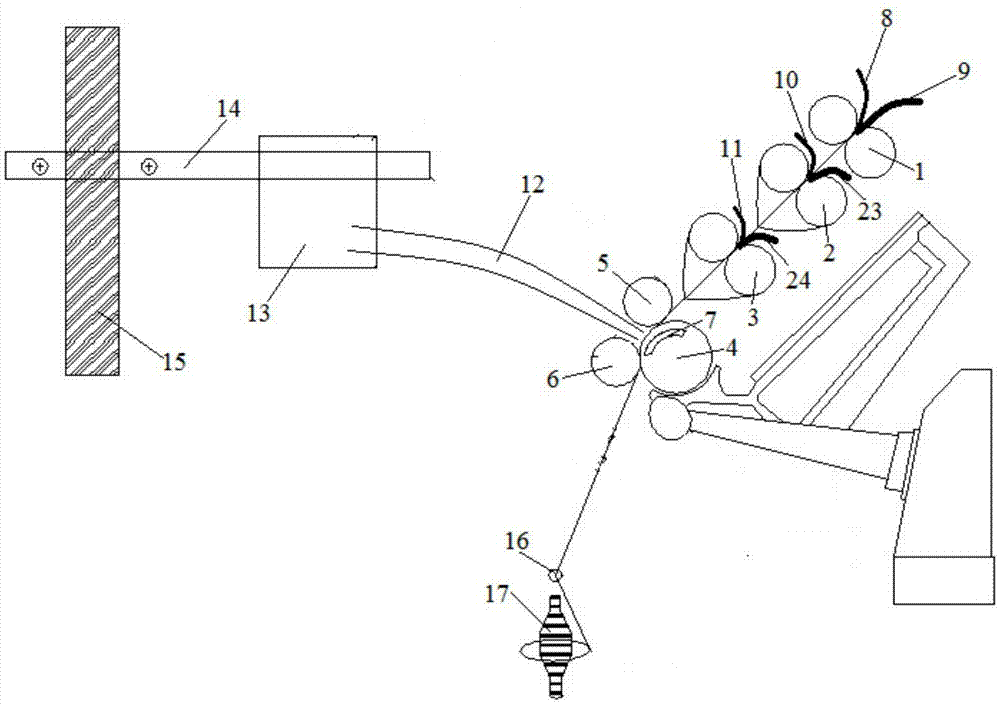

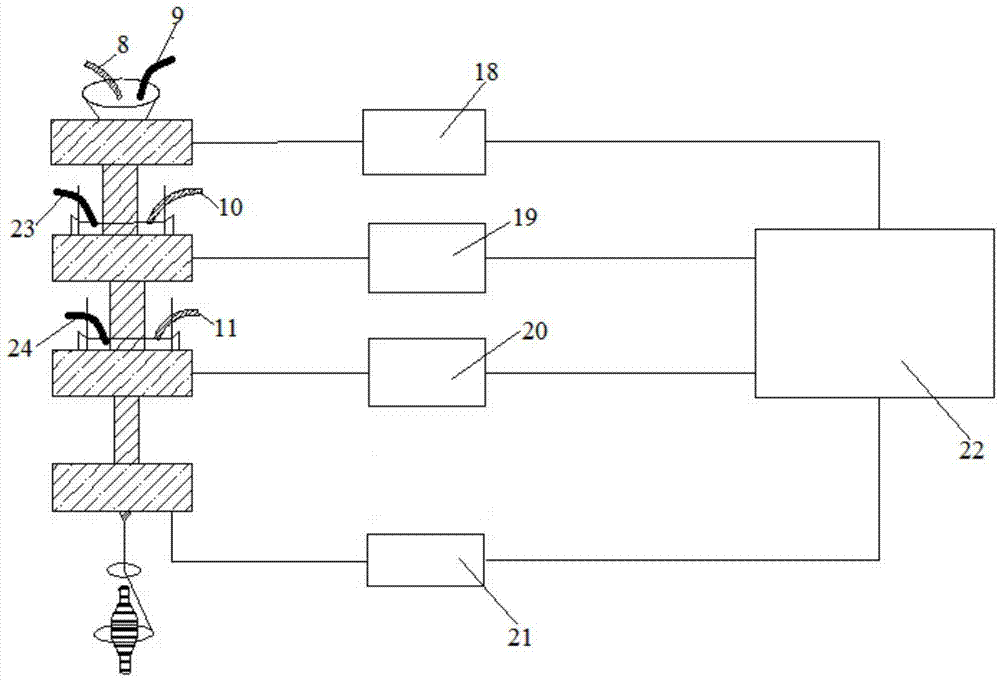

[0014] Depend on figure 1 and figure 2 As shown, a multi-moiré color blended yarn includes a main body spun yarn, and loose fiber-like velvet fibers are wrapped in the main spun yarn. The velvet fibers are apocynum fibers or yak wool fibers or cashmere fibers or camel hair fibers. The surface is attached with discontinuous first spun yarn 8, second spun yarn 10 and third spun yarn 11, the third spun yarn 11 is continuously attached to the surface of the main spun yarn, and the first spun yarn 8 and the second spun yarn 10 are intermittently attached to the surface of the main spun yarn , the first spun yarn 8, the second spun yarn 10 and the third spun yarn 11 are all colored spun yarns, the colors of the first spun yarn 8, the second spun yarn 10 and the third spun yarn 11 are different, the first spun yarn 8, the second spun yarn 10 and the third spun yarn The material of the spun yarn 11 is the same as that of the main spun yarn.

[0015] A production device for multi-mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com