Stability enhancement structure of turbocharger compressor

A turbocharger and compressor technology, which is applied to machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of reduced compressor efficiency, compressor damage, and stable operating range restrictions, and achieves reduction of blade clearance. The effect of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

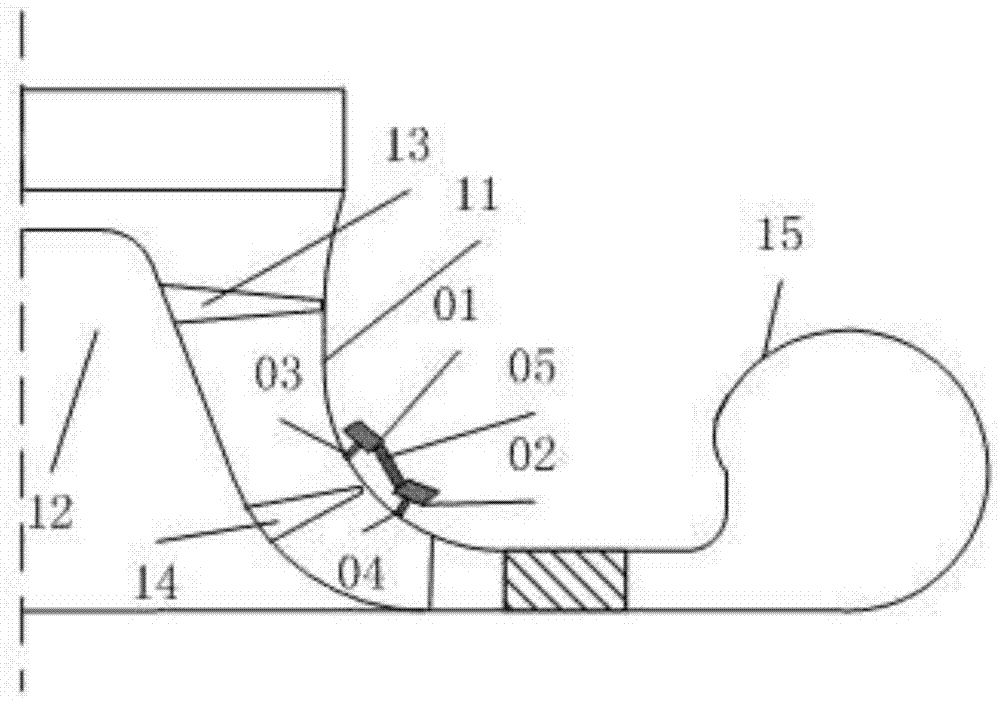

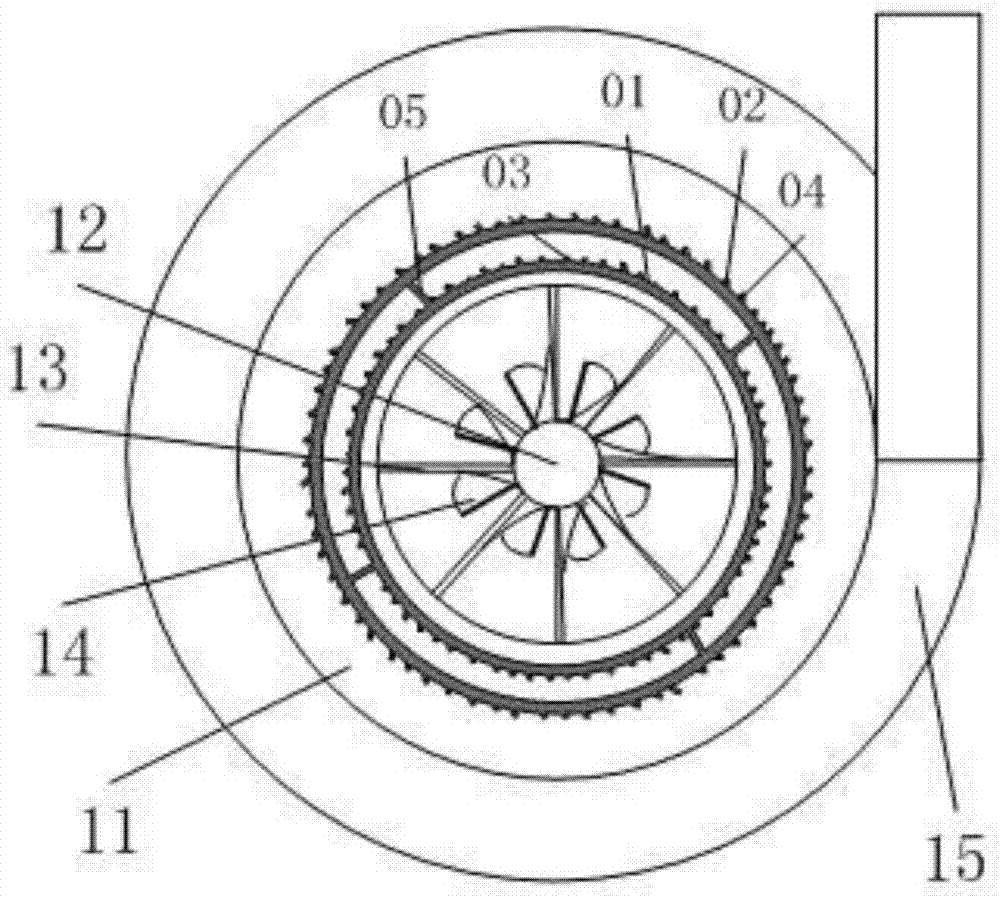

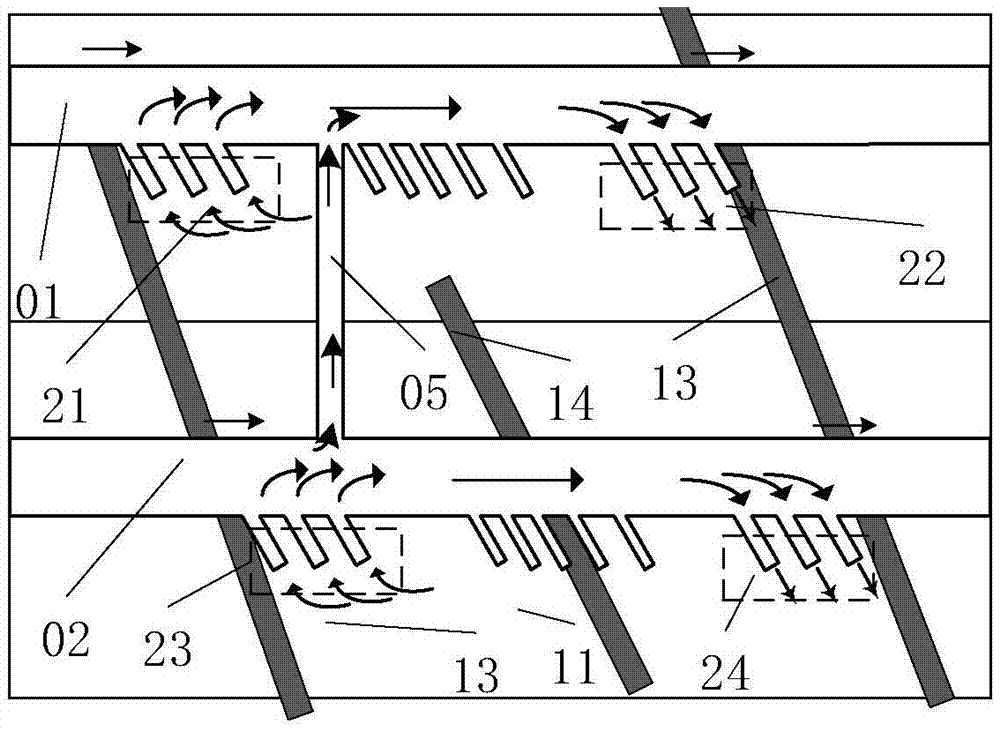

[0014] Combine Figure 1~3 , The present invention adds a tunnel structure to the compressor. The compressor used is a general turbocharger compressor, and its structure includes: a compressor casing 11, a compressor impeller 12, a main blade 13, a splitter blade 14, and a volute 15.

[0015] The characteristic structure of the present invention is that a row A pressure balance pipe 01, a row B pressure balance pipe 02, a row A air hole 03, a row B air hole 04 and a connecting pipe 05 are added to the compressor casing 11.

[0016] The pressure balance pipe 01 of row A and the pressure balance pipe 02 of row B are the first connected annular pipes, and the pressure balance pipes of row A and B are connected by 4 connecting pipes 05. In the present invention, two rows of pressure balance pipes and 4 connecting pipes 05 are used. The actual enginee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com