Integrated hydraulic cylinder with extension and swing functions and application thereof

A hydraulic cylinder, an integrated technology, applied in the field of hydraulic cylinders, can solve the problems of hydraulic cylinders that cannot accurately control the rotation, troublesome manufacturing process, complex structure of hydraulic cylinders, etc., achieve good economic benefits and market value, save manufacturing costs, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

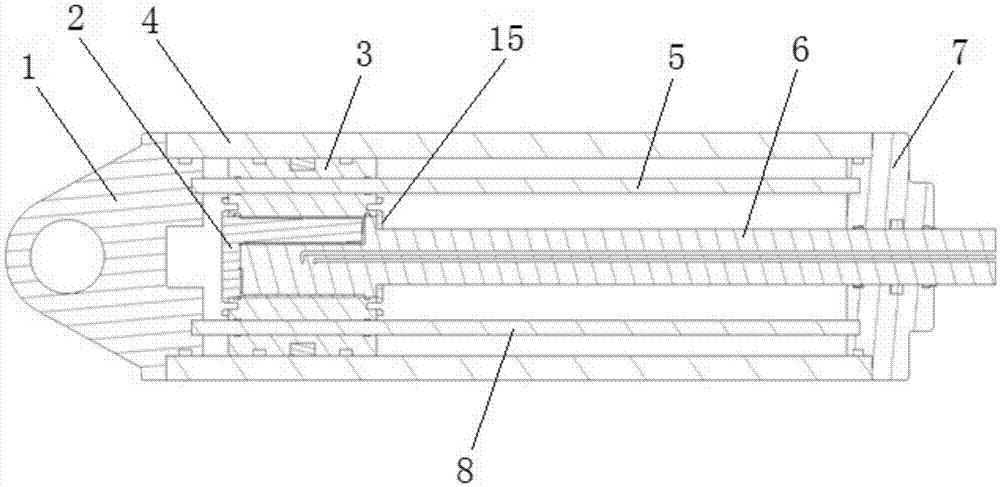

[0032] Such as figure 1 As shown, an integrated hydraulic cylinder with telescopic and swinging functions, including a cylinder bottom 1, a cylinder barrel 4, a cylinder head 7, a piston 3 and a piston rod 6, the piston 3 is placed in the cylinder barrel 4, and the piston 3 contains a cavity A left end cap 2 and a right end cap 15 are respectively installed on both sides of the piston 3, and one end of the piston rod 6 passes through the right end cap 15 and is located in the cavity, and the other end passes through the cylinder head 7.

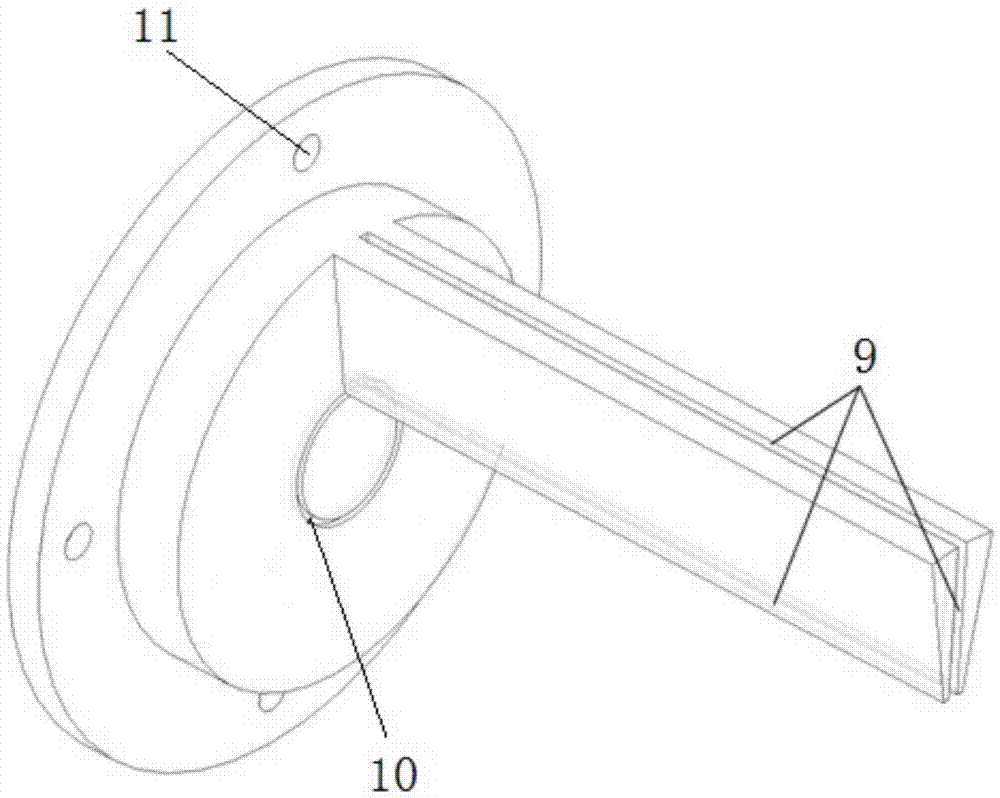

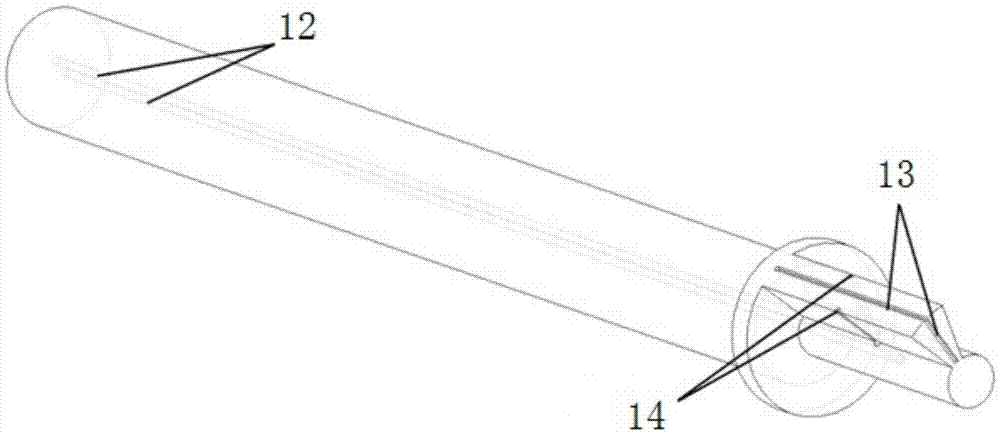

[0033] The left end cover 2 includes a body, the body is a stepped cylinder, including two first cylinders and second cylinders with different diameters, the first cylinder is provided with a bolt hole 11, and the left end cover and the piston 3 are connected by bolts. A partition is arranged on the second cylinder. A disc is arranged on the piston rod, a partition is provided on one side of the disc, two axial holes 12 are provided in the a...

Embodiment 2

[0036] An integrated hydraulic cylinder with telescoping and swinging functions, the structure is as described in Embodiment 1, the difference is that a first groove 13 is provided on the partition plate on the piston rod 6, and a first groove 13 is provided on the partition plate of the left end cover. A second groove 9 is provided, and a third groove 10 is provided on the second cylinder. The third groove 10 is a circular groove. When the piston rod 6 is installed with the left end cover 2, one end surface of the piston rod in contact with the circular groove.

[0037] Gaskets are provided in the first groove 13 , the second groove 9 and the third groove 10 . By adding a gasket in the groove, the hydraulic oil can be truly sealed in the cavity of the piston to prevent leakage, so that the first chamber and the second chamber can be truly isolated from each other, preventing oil from flowing and affecting its rotation Precision control.

Embodiment 3

[0039] An integrated hydraulic cylinder with telescopic and swing functions, the structure is as described in Embodiment 2, the difference is that two guide rods 5 are arranged in the cylinder barrel 4 of the hydraulic cylinder, and the two guide rods 5 are symmetrical It is arranged on the upper and lower sides of the cavity. After the guide rod 5 passes through the piston, its two ends are connected with the cylinder bottom 1 and the cylinder head 7 respectively. When supplying oil to the axial hole to realize the swing function of the piston rod, the guide rod can restrict the rotation of the piston, and only realize the rotation of the piston rod, thereby realizing independent control of the telescopic and swing functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com