Moment-of-inertia test bench based on torque sensor

A technology of torque sensor and moment of inertia, which is used in the testing of machine/structural components, static/dynamic balance testing, instruments, etc., can solve the problems of low efficiency, low repeatability, low measurement accuracy, etc., and achieves simple measurement principle, The effect of high repeatability and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

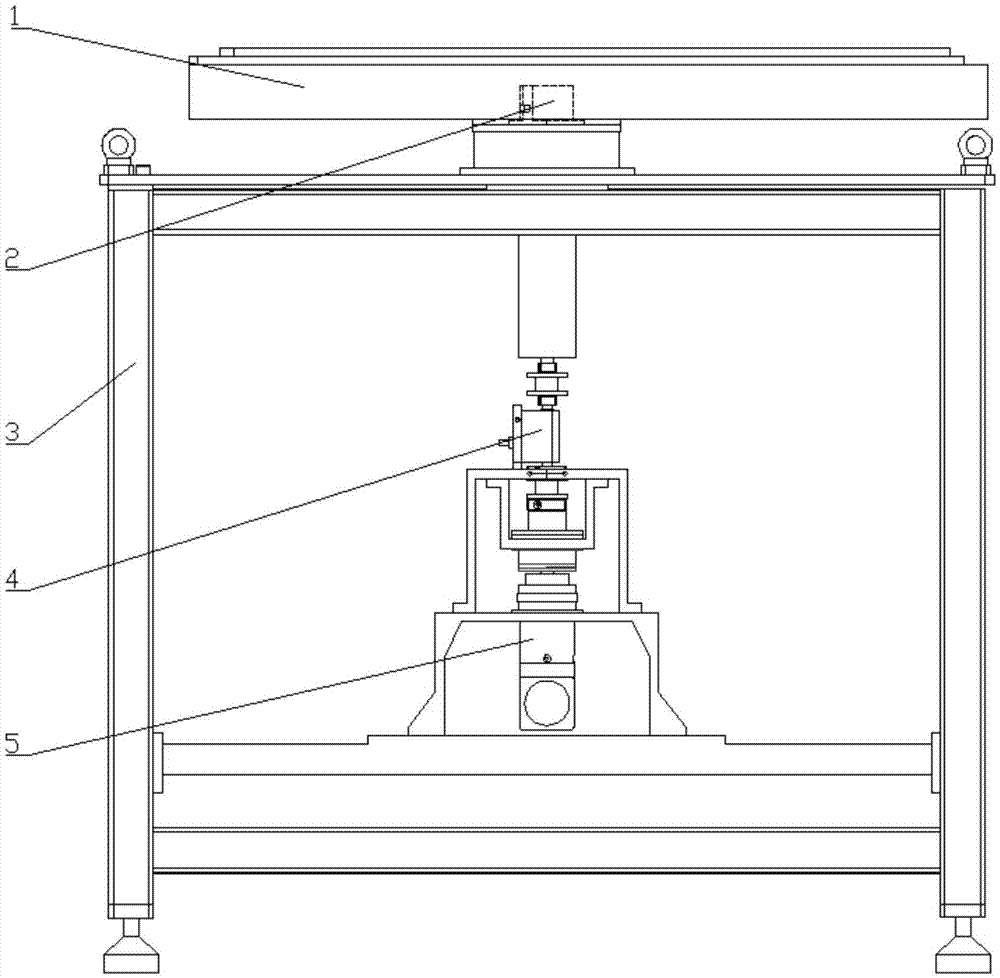

[0022] This embodiment is a moment of inertia test bench based on a torque sensor.

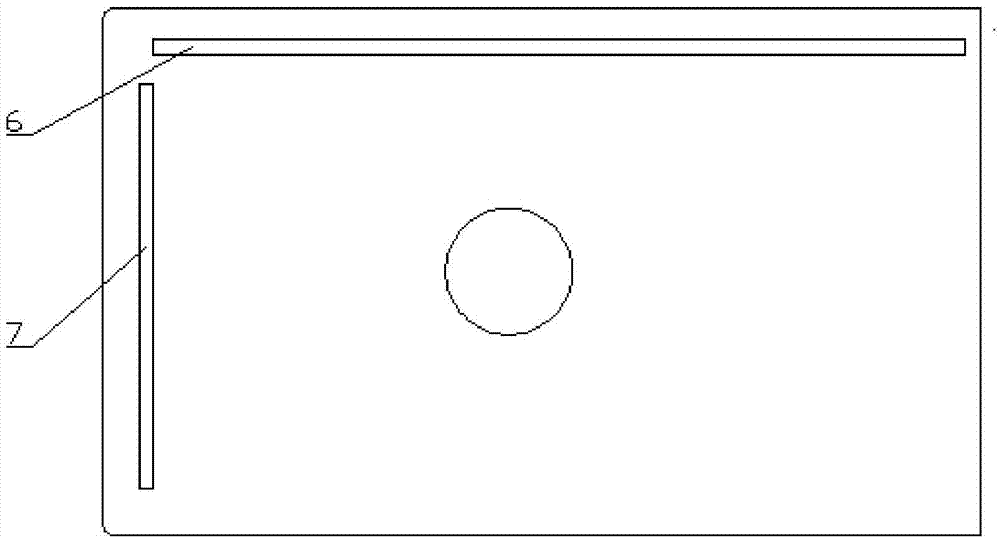

[0023] refer to Figure 1 to Figure 5 , the moment of inertia test bench based on the torque sensor in this embodiment is composed of a workbench, a torsion bar transmission mechanism, a driving device, and an electric control system; The angle between the longitudinal reference bar 7 , the horizontal reference bar 6 and the longitudinal reference bar 7 is 90 degrees, and the transition plate 8 is installed at the center of rotation of the workbench 1 . When testing the object, design a special fixture according to the size of the object to be measured, and place it on the horizontal reference bar 6 and the vertical reference bar 7 on the workbench 1 to position the workbench 1 surface and the fixture.

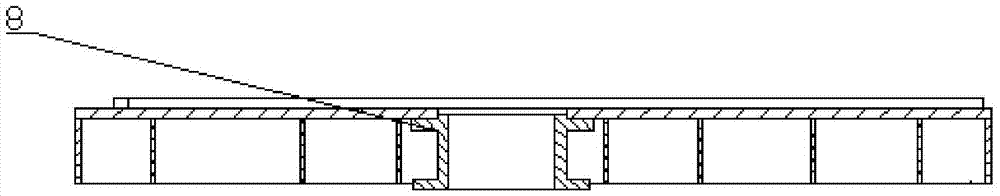

[0024] The torsion bar transmission mechanism includes an angular velocity sensor 2, a thrust ball bearing cover 9, a thrust ball bearing 10, a thrust b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com