On-site programmable LED drive power and programming method

An on-site programming and LED driving technology, which is applied in the direction of electric light source, light source, program control device, etc., can solve the problems of large change range of requirements, high cost, long production cycle of driving power supply, etc., and achieve high operating efficiency and adjustable setting time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

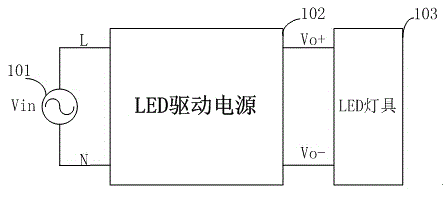

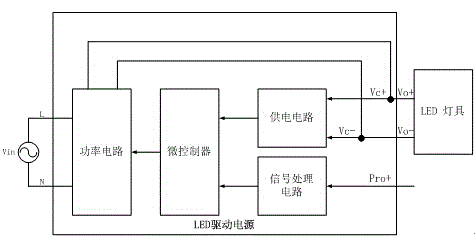

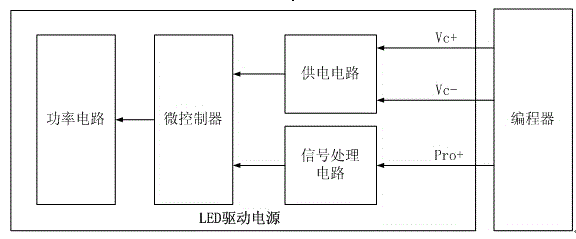

[0029] The embodiment of the present invention provides an LED power supply capable of field programming and a programming method. It is applied to the LED driving power supply and can provide suitable driving current or voltage for various LED lamps. More specifically, the LED driving power supply of the present invention can provide different output ratings through field programming. The programming signal in the present invention may be the output rated current value, rated voltage value and protection point of the LED drive power supply, voltage and current power-on output value, timing parameters of the timing operation mode, etc. In order to make the content of this disclosure more comprehensible, the following embodiments are specifically cited as examples on which this disclosure can indeed be implemented. In addition, wherever possible, components / members / steps with the same reference numbers in the drawings and embodiments represent the same or similar parts.

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com