Method for electrochemical polishing of metal interconnection wafer structure

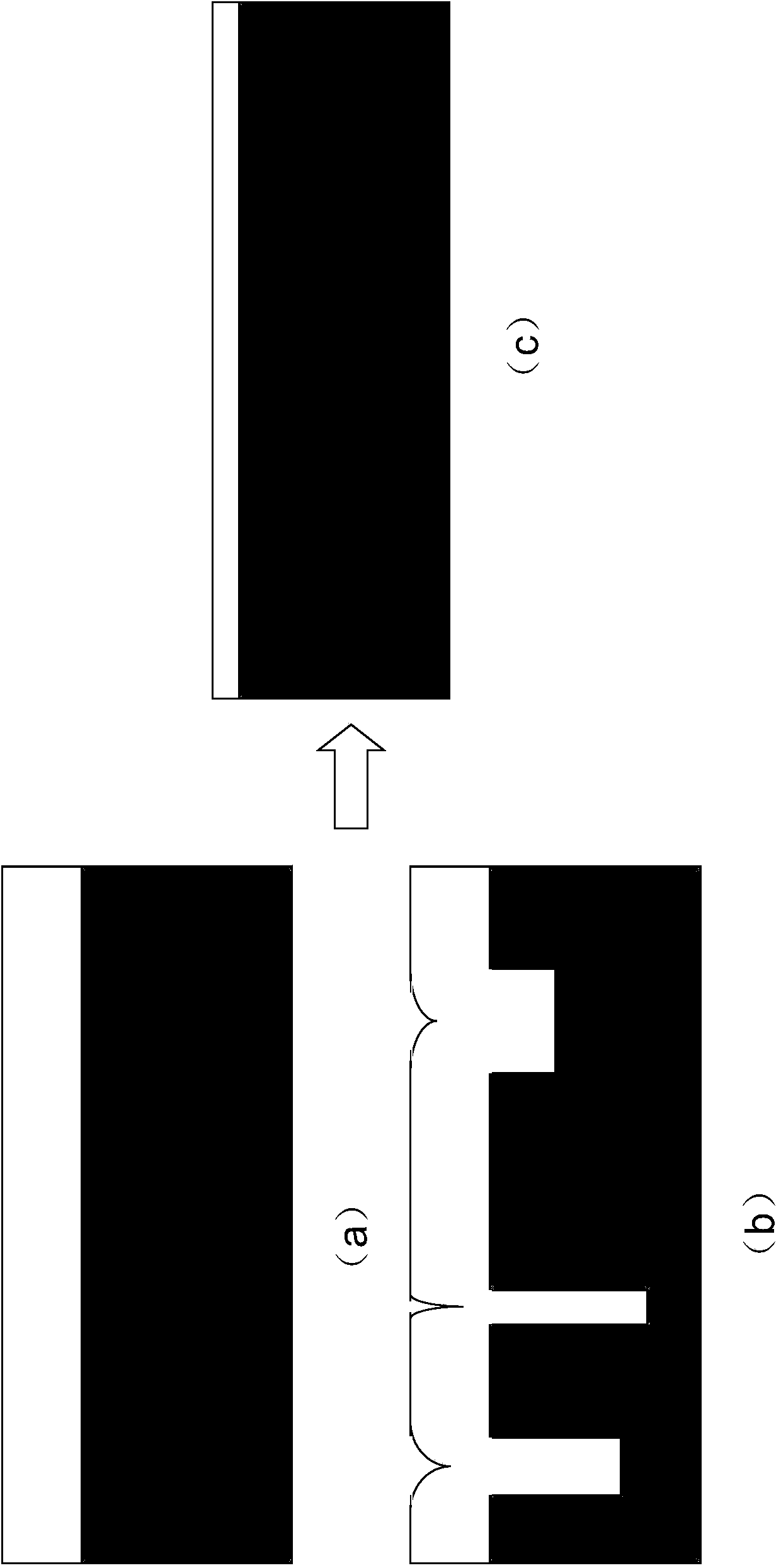

A technology for polishing metal and electrochemistry, applied in the field of electrochemical polishing, can solve the problems of inability to be directly equivalent, the calculation method is not rigorous enough, and the polishing yield is low, and the effect of improving the yield is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

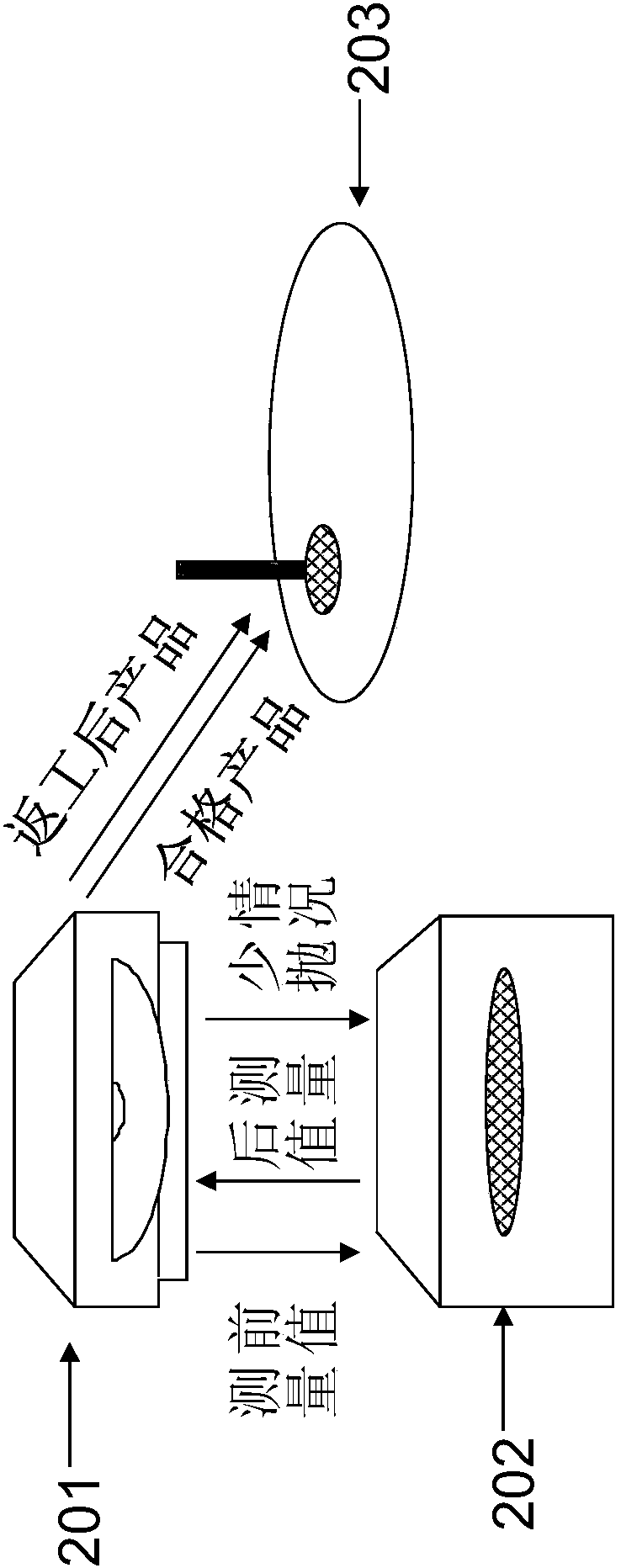

Method used

Image

Examples

Embodiment approach

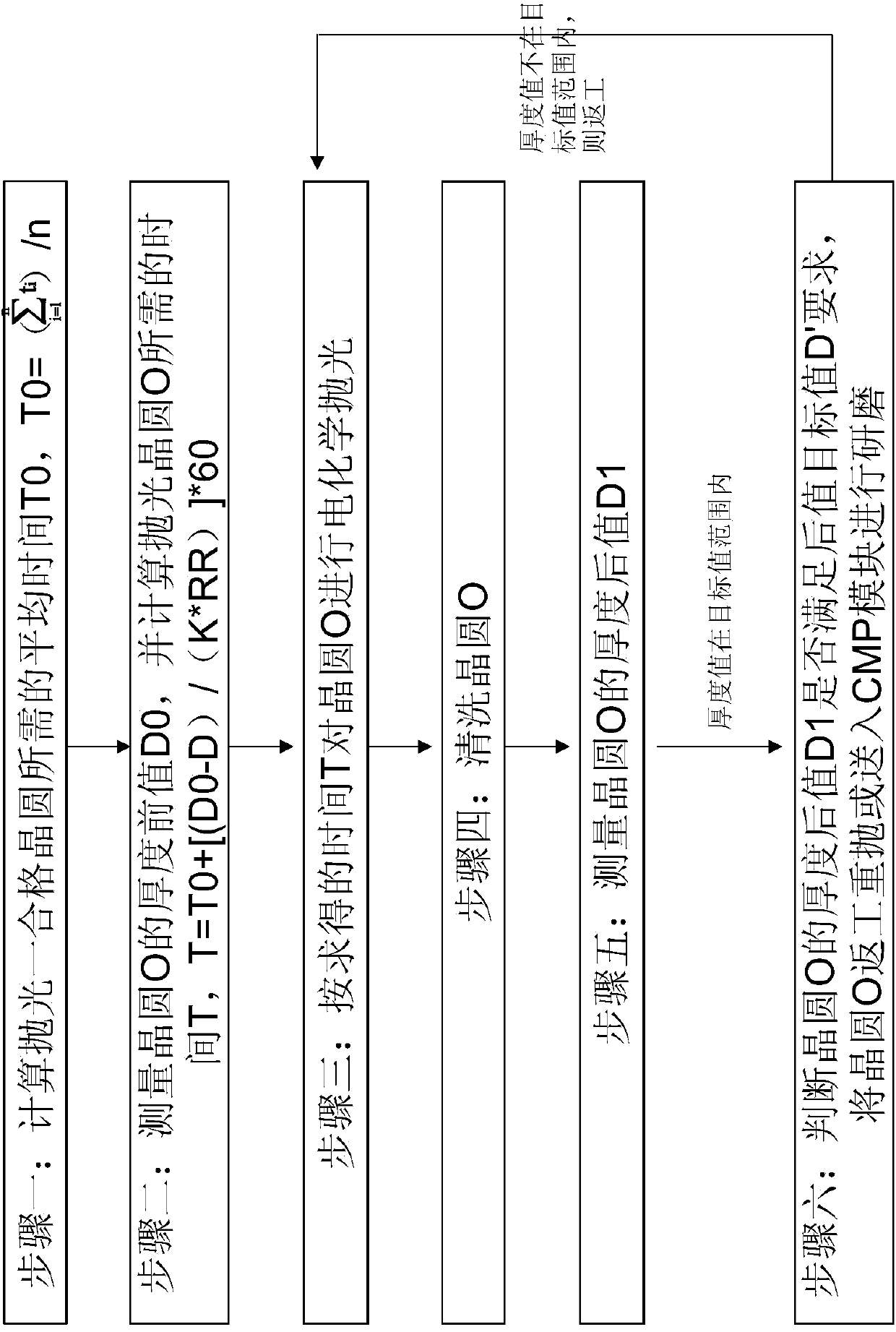

[0052] Step 1: Calculate the average time T0 required for polishing a qualified wafer according to the polishing results of the first N batches, where N=20, T 0 = ( Σ i = 1 n t i ) / n ;

[0053] Step 2: Measure the thickness of wafer O before D0, compare it with the target value D of the previous value, and calculate the required polishing wafer O according to the formula T=T0+[(D0-D) / (K*RR)]*60 time T;

[0054] Step 3: Perform electrochemical polishing on the wafer O according to the obtained time T;

[0055] Step 4: cleaning wafer O;

[0056] Step 5: Measure the thickness D1 of the wafer O;

[0057] Step 6: Determine whether the post-thickness value D1 of the wafer O satisfies the requirement of the post-value target ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com