Break-resistant high-energy-density lithium ion battery positive plate and preparation method

A lithium-ion battery, high energy density technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems affecting battery electrical performance and safety performance, cell failure, etc., and achieve high production efficiency and stable structure. , the effect of strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

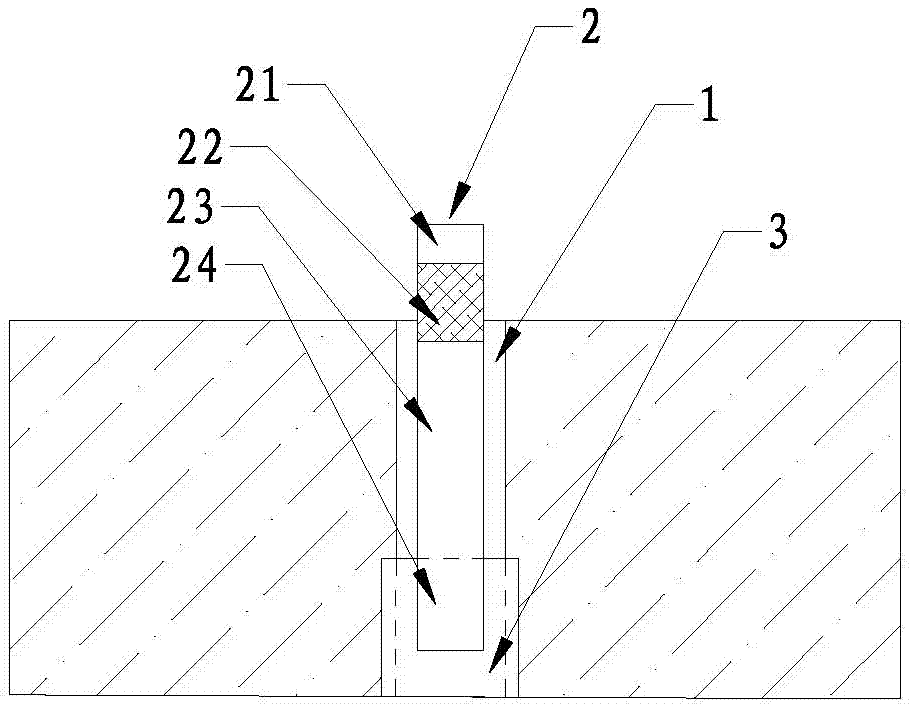

[0036] A high-energy-density lithium-ion battery positive electrode sheet for anti-fracture, comprising a first positive electrode material layer, an aluminum foil and a second positive electrode material layer from top to bottom, such as image 3 As shown, the surface of the aluminum foil is provided with an empty aluminum foil part 1 arranged vertically, the empty aluminum foil part 1 is welded with a positive electrode ear 2, and the lower half surface of the empty aluminum foil part 1 is pasted with an anti-crack glue 3, and the positive electrode The ear 2 includes a cap welding part 21, a middle welding part 23 and a tail part 24 from top to bottom. The tail part 24 is attached to the surface of the anti-break adhesive 3, and the middle welding part 23 is arranged on the empty aluminum foil part. 1, the cap welding portion 21 of the positive tab 2 protrudes from the upper end of the hollow aluminum foil portion 1 .

[0037] Put a layer of anti-fracture glue 3 on the empt...

Embodiment 2

[0042]The difference between the present embodiment and the first embodiment is that there is also a wrapping glue portion 22 between the cap welding portion 21 and the middle welding portion 23 of the positive tab 2 , and the wrapping glue portion 22 is provided with a wrapping glue. After the positive pole ear 2 is welded, the cap will be bent into the steel shell, and the glue can prevent the positive pole ear 2 from touching the negative pole steel shell and short-circuiting. The width of the rubber-wound portion 22 is consistent with the width of the positive tab 2 , and the length of the rubber-wound portion 22 is 13-15 mm.

[0043] Preferably, in this embodiment, the lower end of the glue-wound part 22 is arranged on the upper end of the hollow aluminum foil part 1, that is, the glue-wrapped part 22 is partly exposed outside the aluminum foil, and partially penetrates into the aluminum foil, so as to further prevent the positive electrode ear 2 from When the aluminum fo...

Embodiment 3

[0048] The difference between this embodiment and embodiment 2 is that: the apex angles of the cross section of the positive tab 2 are all smooth and rounded. The cross-section of the traditional positive tab 2 is generally square, and the presence of right angles will generate more sharp edges, and it is easy to break down the aluminum foil when a high-energy current is formed instantaneously. Therefore, in this embodiment, the right angle of the positive tab 2 is changed to a rounded corner, and The surface of the positive tab 2 is smoothed to reduce burrs and the risk of easy breakdown, improve the safety performance of the battery, and also increase the life of the battery.

[0049] The surface of the positive tab 2 is also covered with tab glue, which seals the burrs on the edge of the positive tab 2 and the welding mark, and prevents the burrs from piercing the diaphragm after winding to cause an internal short circuit. Preferably, the width of the tab glue is greater tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com