Current collector preparation method

A current collector, thickness direction technology, applied in the field of current collector preparation, can solve the problems of reducing electrochemical cell capacity and energy conversion efficiency, increasing the contact resistance of electrode active material metal layer, etc., to improve battery capacity and conversion efficiency, prevent Corrosion reaction, effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The current collector provided by the present invention and its preparation method will be further described in detail below with reference to the accompanying drawings and specific embodiments.

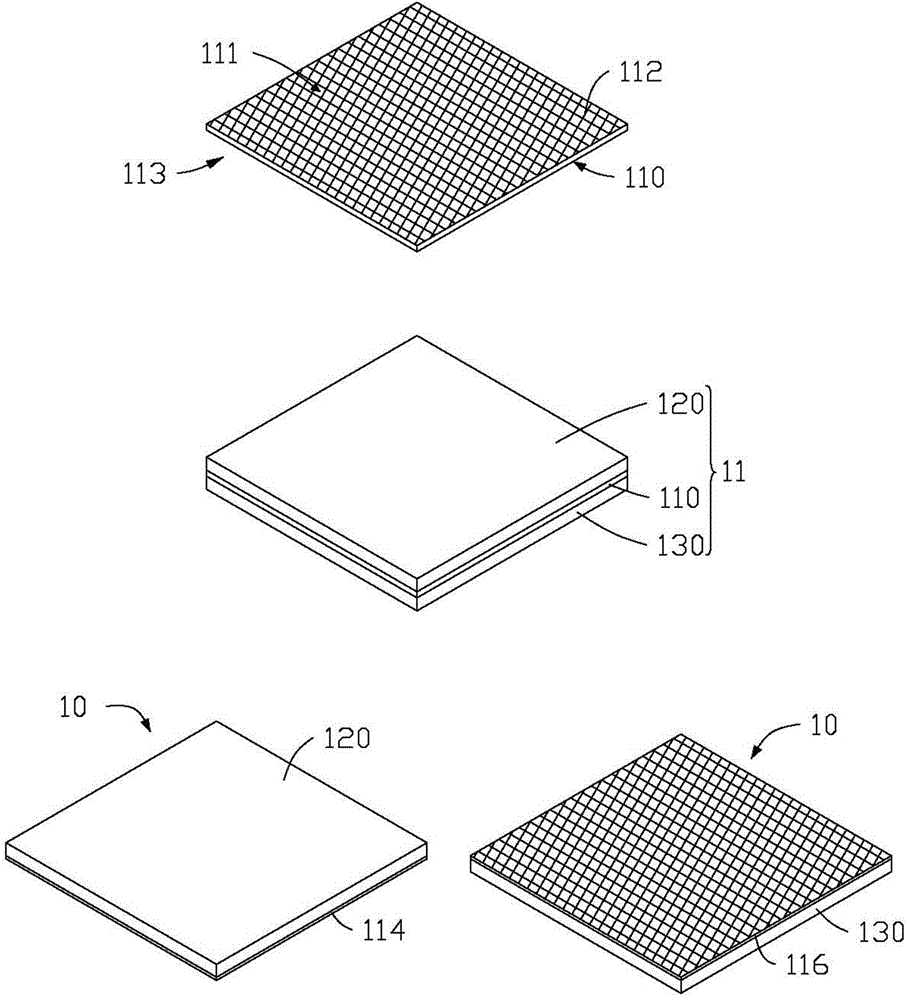

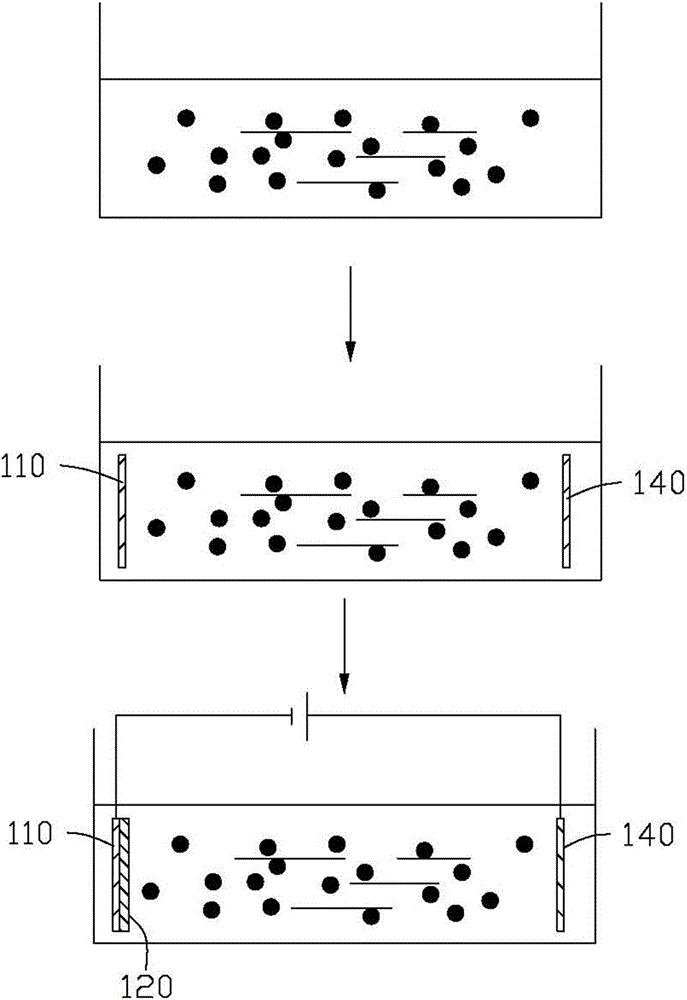

[0018] see figure 1 , the present invention also provides a method for preparing the current collector 10, comprising the following steps:

[0019] Step S10, providing a carbon nanotube layer 110, the carbon nanotube layer 110 including a first surface 111 and a second surface 113 opposite to each other;

[0020] Step S11, electroplating a first metal layer 120 on the first surface 111 of the carbon nanotube layer 110, and electroplating a second metal layer 130 on the second surface 113 of the carbon nanotube layer 110 to form a carbon nanotube composite layer 11; and

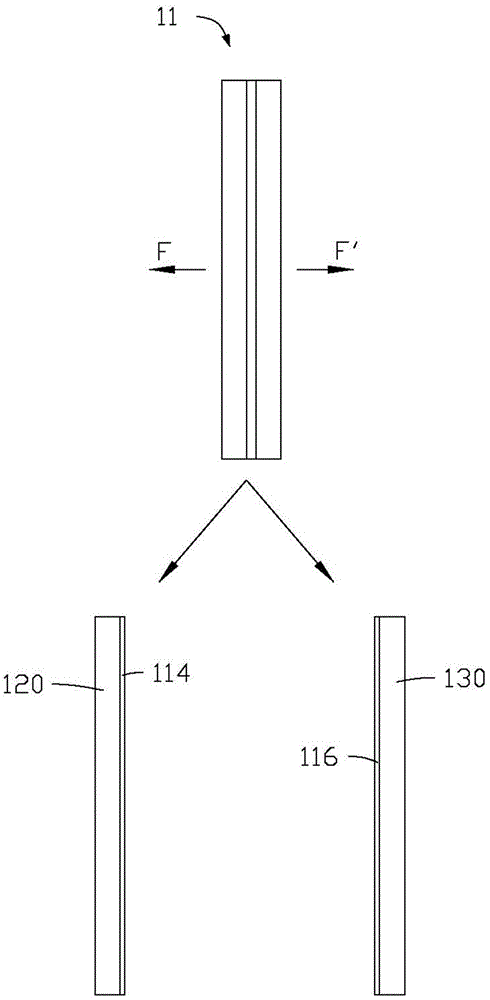

[0021] Step S12, tearing off the carbon nanotube composite layer 11, so that the carbon nanotube layer 110 is divided into a first sub-carbon nanotube layer 114 and a second sub-carbon nanotube layer 116, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com