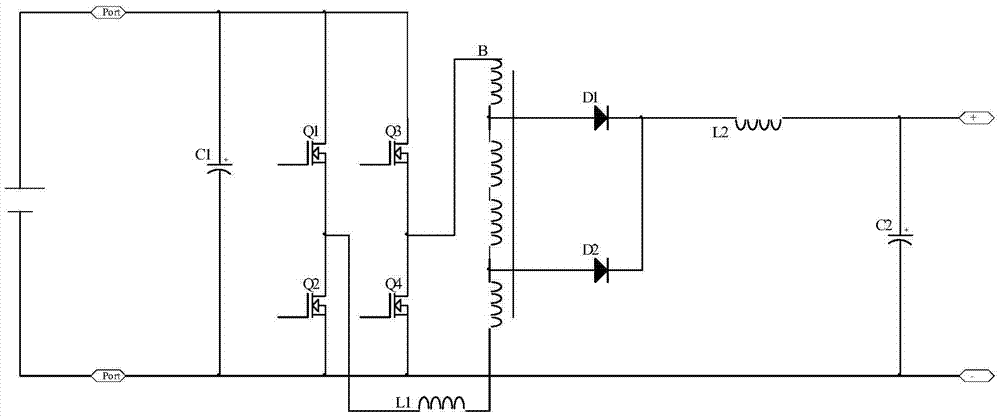

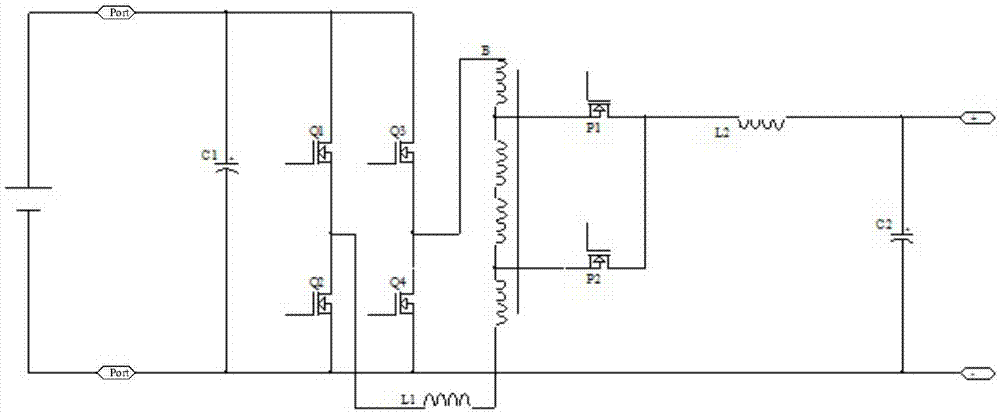

Chained double-bridge self-coupled stepdown topology

A chain-type, self-coupling technology, applied in the direction of instruments, electric variable adjustment, output power conversion devices, etc., can solve the problems of failure mode hazards, low output power, large volume, etc., to achieve the elimination of energy loss, high power density, Solve the effect of low output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

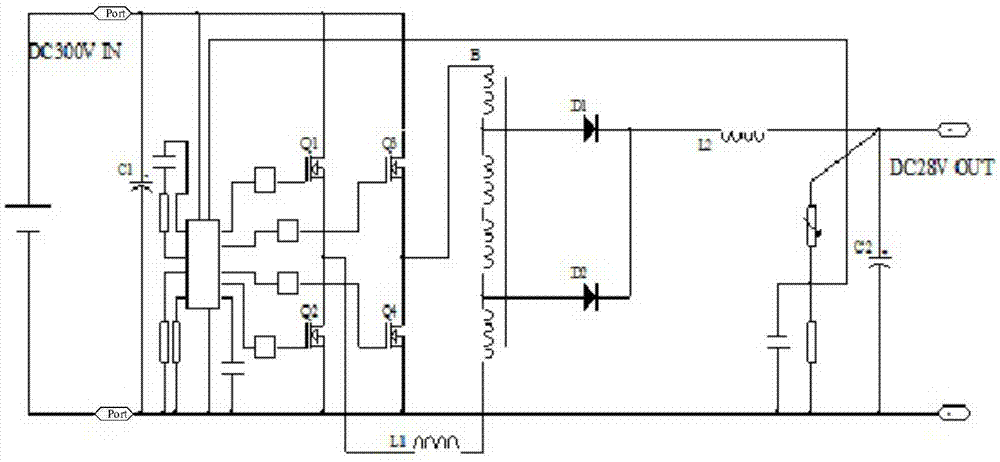

[0048] Applications in the field of buck conversion:

[0049] The power supply is generally DC280V. Many high-power electronic devices need to provide DC28V voltage. The output power of the original circuit form is 0-600W, but the output power can be increased to 3000W by using the "chain double bridge auto-coupling step-down topology". And small size, light weight, more suitable for the use of the environment.

[0050] The topology of the circuit adopts "chain-type double-bridge auto-coupling step-down topology". The main transformer B of the circuit uses EE55 magnetic core, Q1, Q2, Q3, and Q4 use C2M0160120D, and D1 and D2 use MUR3020. Set the working frequency to 280KHz, the main transformer B adopts the following Figure 10 The output power is 3000W and the measured efficiency is 96.2%.

[0051] Finally, it should be noted that obviously, the above-mentioned embodiments are only examples for clearly illustrating the present invention, rather than limiting the implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com