High porosity abradable coating

A porosity, coating technology for gas turbine engine applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

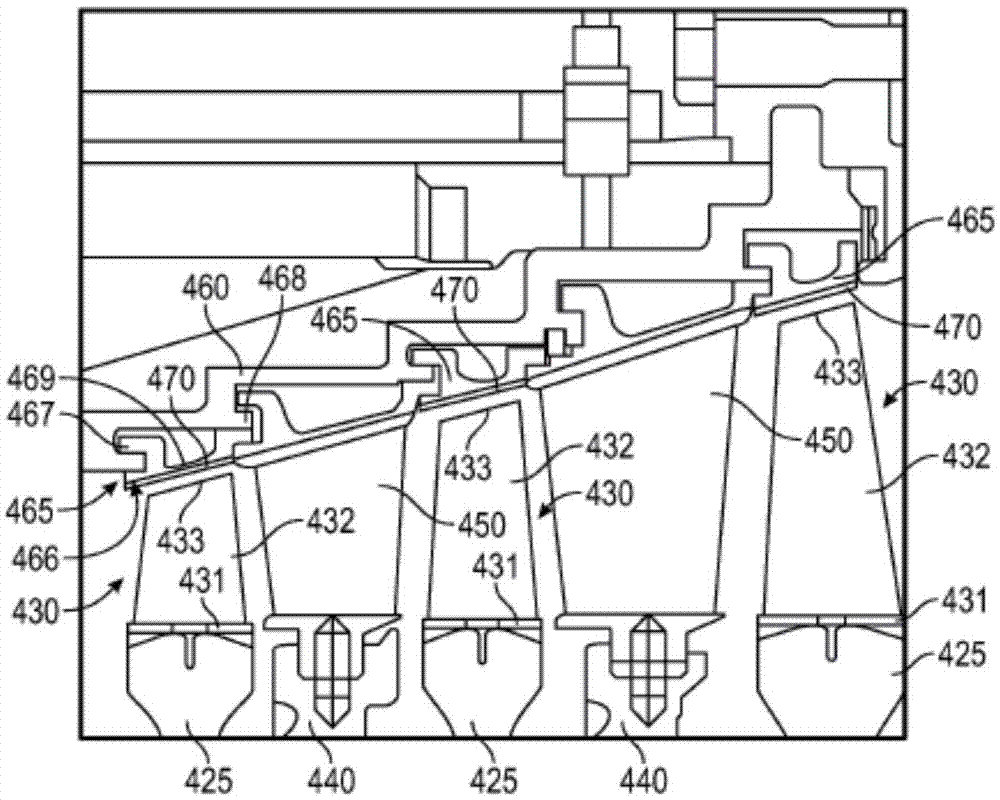

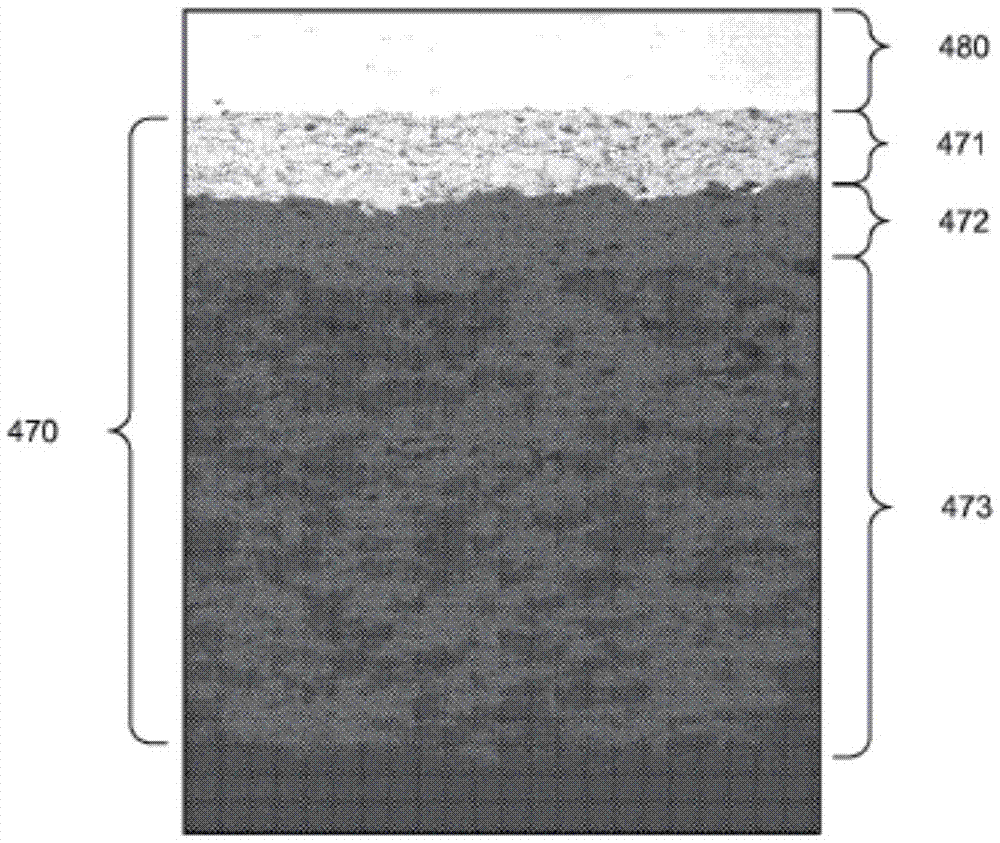

[0008] The systems and methods disclosed herein include abradable coatings for gas turbine engine components. In an embodiment, the abradable coating includes a bond coating, an intermediate layer, and a porous layer. The bond coating includes a metal material, the intermediate layer includes a ceramic material, and the porous layer includes a ceramic material having a porosity (for example, 35% or more of its volume). The bond coat and intermediate layer can provide support and structure for the porous layer. The intermediate layer can also improve the durability of the abradable coating. The porous layer can reduce the wear of the turbine blade and the bare metal tip or the turbine blade without wearing the ceramic tip.

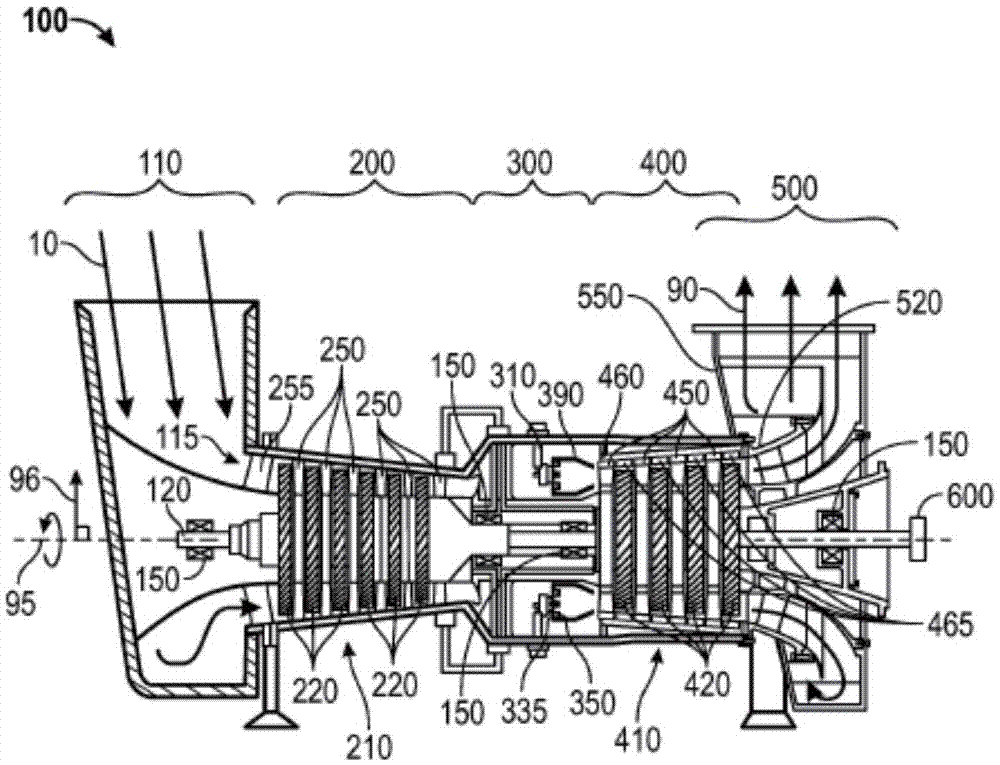

[0009] figure 1 It is a schematic diagram of an exemplary gas turbine engine 100. For clarity and ease of description, some surfaces have been omitted or enlarged (in this figure and other figures). In addition, the present invention may refer to a forward...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com