A kind of porous micron copper ball and its preparation method

A technology of copper balls and copper sources, applied in the field of porous micron copper balls and their preparation, can solve the problems of complicated preparation process operation, long production cycle, simple preparation process, etc., and achieves simple and easy operation of the process flow, green and mild reaction conditions, The effect of high monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 3.2g of copper nitrate, 5mL of polypropionic acid, and 8mL of triethylamine into 80mL of ethanol solvent in sequence, stir well and then add 3mL of hydrazine hydrate. After reacting at room temperature for 60min, centrifuge and wash 4 times with 8000r / min deionized water, and take the precipitate in a vacuum Dry at room temperature for 6 hours under the condition that the density is less than 0.01MPa to obtain porous micron copper balls.

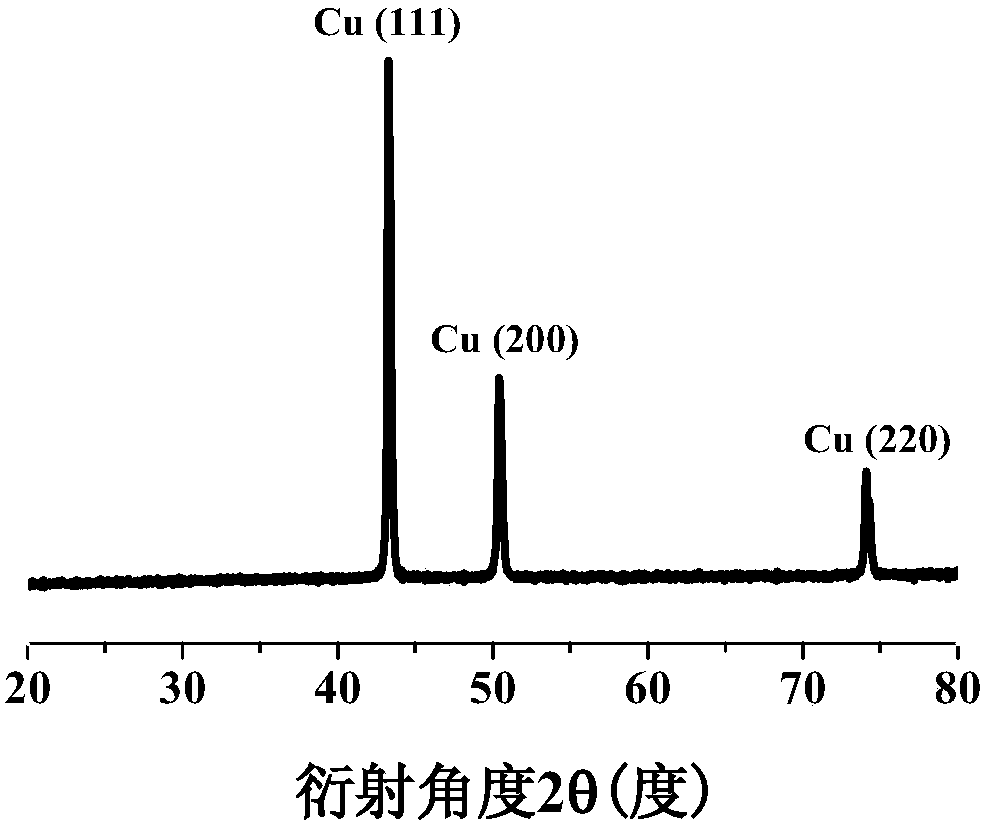

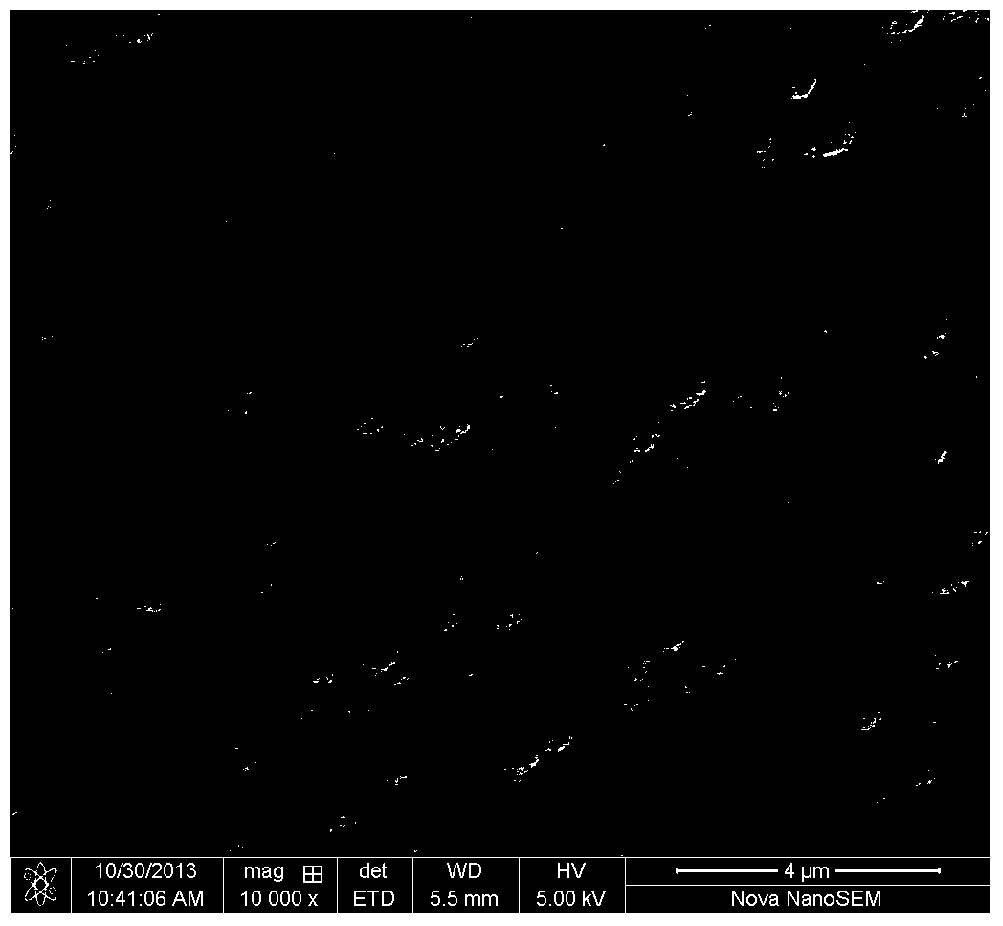

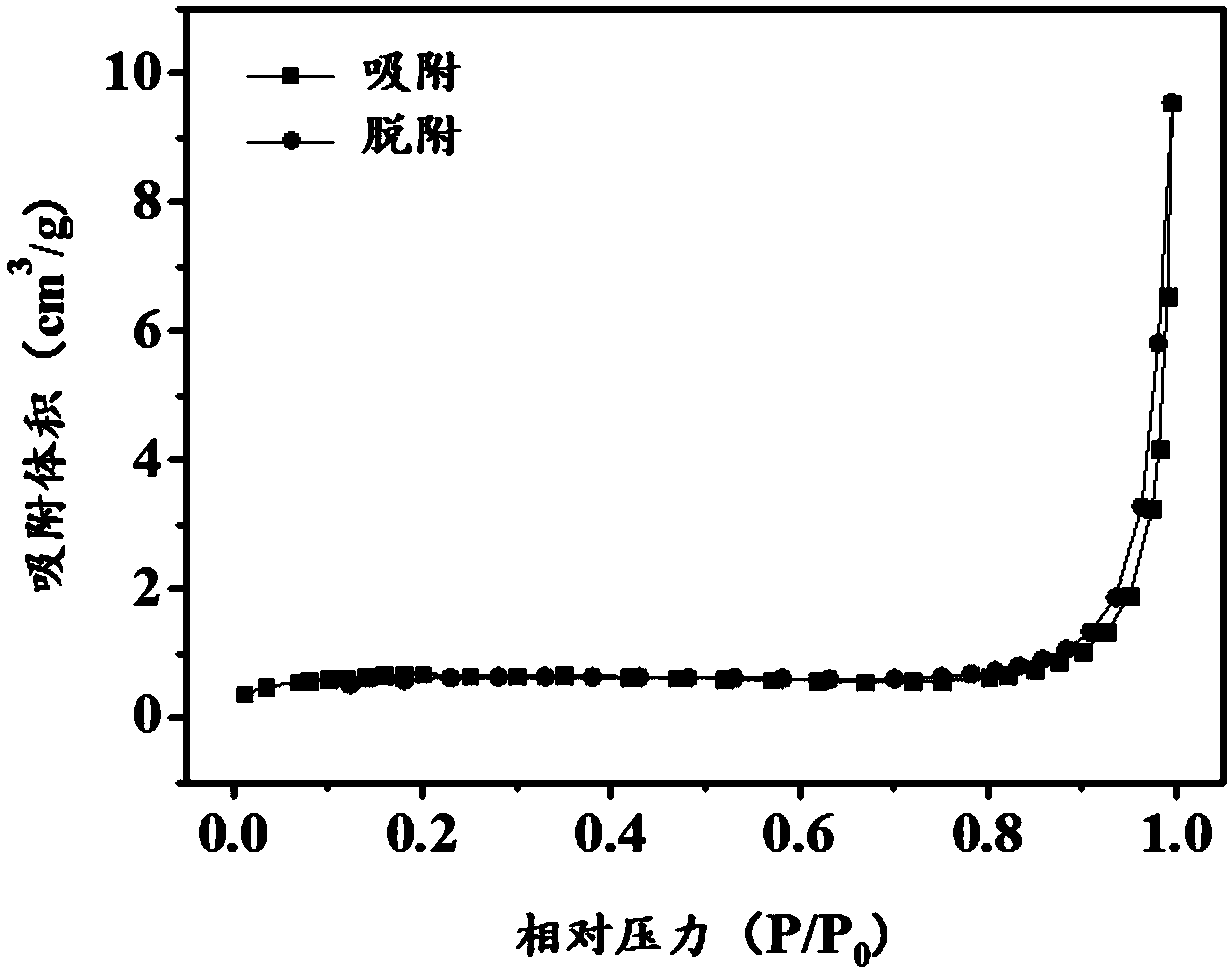

[0029] Get the porous micro-copper ball obtained above, adopt X-ray diffractometer (XRD) to carry out phase spectrum analysis to it, adopt field emission scanning electron microscope (SEM) to observe the morphology of particle, adopt specific surface area analyzer (BET) to test The specific surface area of the particles, the results are as follows figure 1 , figure 2 with image 3 shown. from figure 1 The characteristic peaks of metal copper can be seen in , without any characteristic peaks of the second phases such as cupr...

Embodiment 2

[0031] Add 5.5g of copper hydroxide, 8mL of polyacrylic acid, and 5mL of trioctylamine into 450mL of diethylene glycol solvent in sequence, stir evenly, add 5mL of hydrazine hydrate, react at room temperature for 100min, and then centrifuge and wash with 6000r / min deionized water for 4 The second time, take the precipitate and dry it at room temperature for 8 hours under the condition that the vacuum degree is less than 0.01MPa to obtain porous micron copper balls.

[0032] The XRD pattern, SEM pattern and nitrogen isothermal adsorption curve of the prepared copper-silver alloy nanosheets are similar to those in Example 1, showing that the phase of the porous micron copper balls is metallic copper, without other impurities; the size is 60-80nm The pores are evenly distributed, the particle size of the microspheres is uniform, the dispersion is good, and there is no obvious agglomeration.

Embodiment 3

[0034] Add 2.1g of copper acetylacetonate, 3mL of lauric acid, and 5mL of tetraethylenepentamine into 100mL of glycerol solvent in sequence, stir well and then add 10mL of hydrazine hydrate. After reacting at room temperature for 180min, centrifuge and wash with 5000r / min deionized water for 4 times. Take the precipitate and dry it at room temperature for 10 h under the condition that the vacuum degree is less than 0.01 MPa to obtain porous micron copper balls.

[0035] The XRD pattern, SEM pattern and nitrogen isotherm adsorption curve of the prepared copper-silver alloy nanosheet are similar to those in Example 1, showing that the phase of the porous micron copper ball is metallic copper, without other impurities; the size is 60-80nm The pores are evenly distributed, the particle size of the microspheres is uniform, the dispersion is good, and there is no obvious agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com