Engraving and milling machine with tool magazine device

A library device, engraving and milling machine technology, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of inconvenient use and replacement, complex overall structure, increased manufacturing costs, etc., to achieve fast tool change time, Guarantee the effect of tool change quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

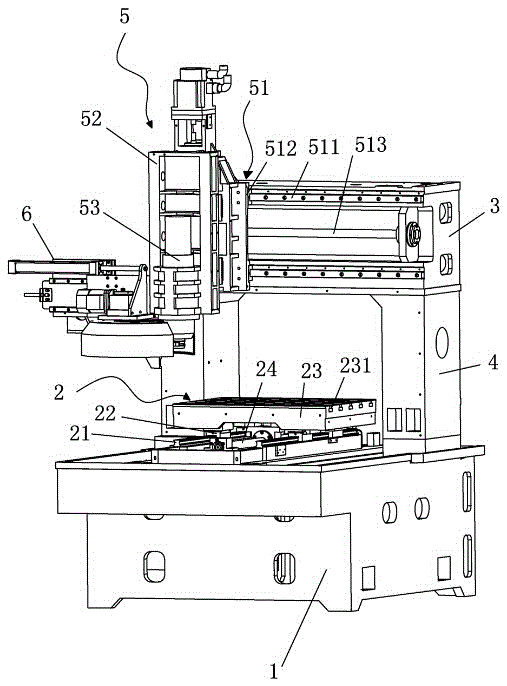

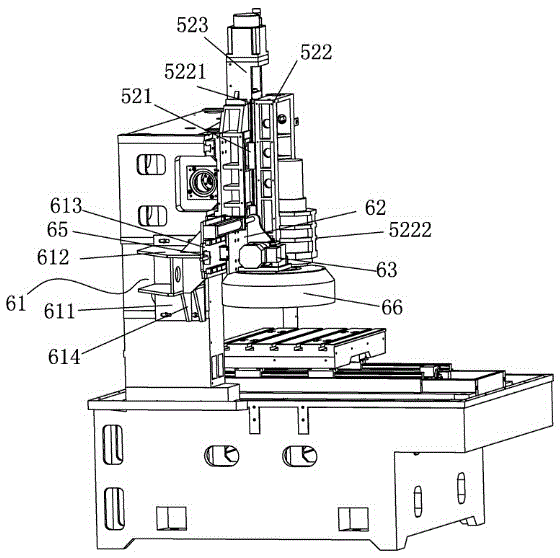

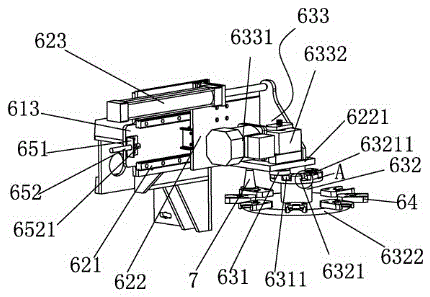

[0033] Example 1: Reference figure 1 , a new type of engraving and milling machine, a kind of engraving and milling machine with a tool magazine device, including a base 1, a mobile worktable 2 arranged on the base 1, a beam 3 arranged above the mobile workbench 2, a 2 The columns 4 on both sides for supporting the beam 3 and the spindle device 5 arranged on the beam 3 are characterized in that they also include a rotary tool magazine device 6, and the rotary tool magazine device 6 includes a fixed bracket 61 fixedly arranged on the side of the column , the moving device 62 that is fixed on the fixed bracket 61, the rotary tool magazine seat 63 that is arranged on the mobile device 62 and some cutter head fixtures 64 that are arranged on the rotary tool magazine seat 63, the cutter head holder 64 is clamped with different types of Cutter head7.

[0034] The fixed bracket 61 includes a fixed side plate 611 for fixing, a fixed upper plate 612 arranged on the fixed side plate 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com