Safety protective cover structure used on section production line

A safety protection and production line technology, applied in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems affecting the operation of the machine head, hidden dangers of the production environment, etc., to facilitate recovery and recycling, and reduce production costs. , to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

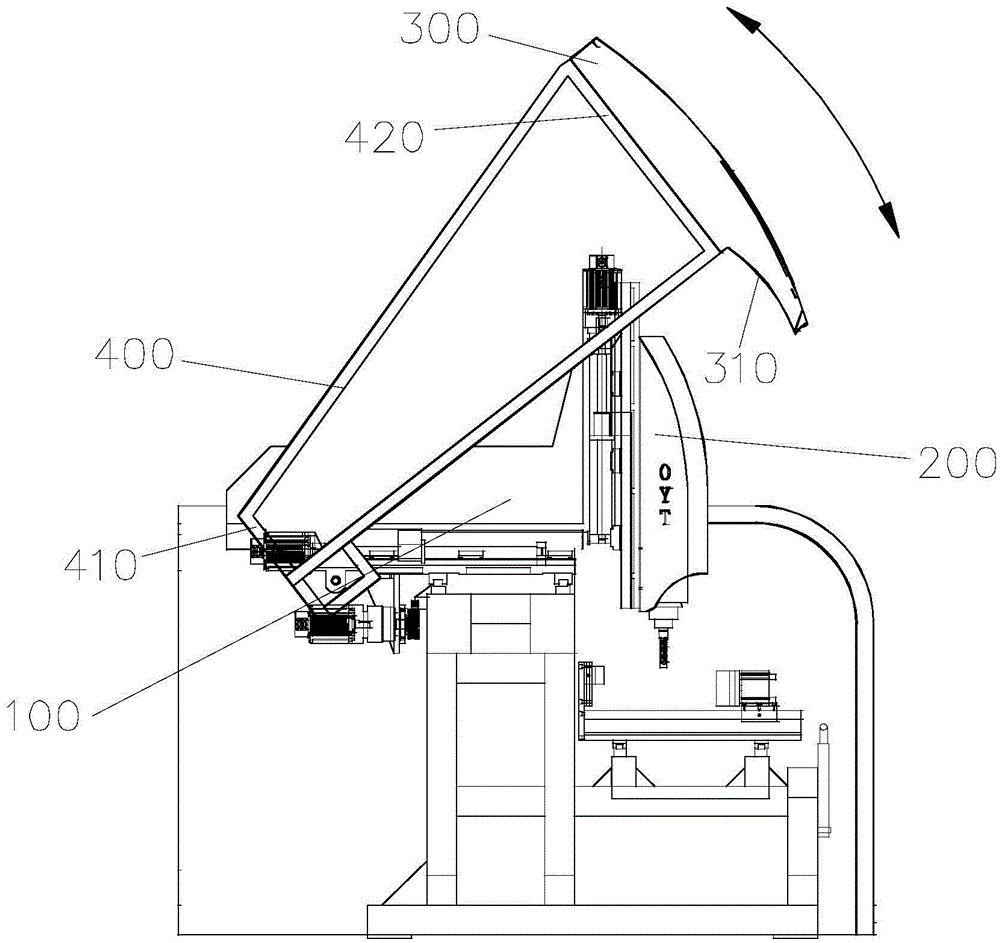

[0016] Such as figure 1 As shown, a safety shield structure used on a profile production line includes a head holder 100, a head 200 arranged on the head holder 100, and a head outside the head 200 for protecting the safety of the head 200. Protective cover 300 . By installing a safety shield 300 at the machine head 200, the problem of debris splashing when the machine head 200 processes profiles is solved. The safety shield 300 will block the debris and prevent the debris from splashing outward, which can not only ensure the production of the production environment For safety, a debris recycling device can also be installed under the safety shield 300 to recover the debris, which can not only ensure the cleanliness of the production en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com