Ink droplet volume calibration method, calibration system thereof, and printing device

A calibration method and calibration system technology, which is applied in volume measurement testing/calibration, volume measurement instrument/method, printing, etc., can solve the problems of error and low measurement accuracy, and achieve the goal of improving measurement accuracy and accurately measuring ink drop volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

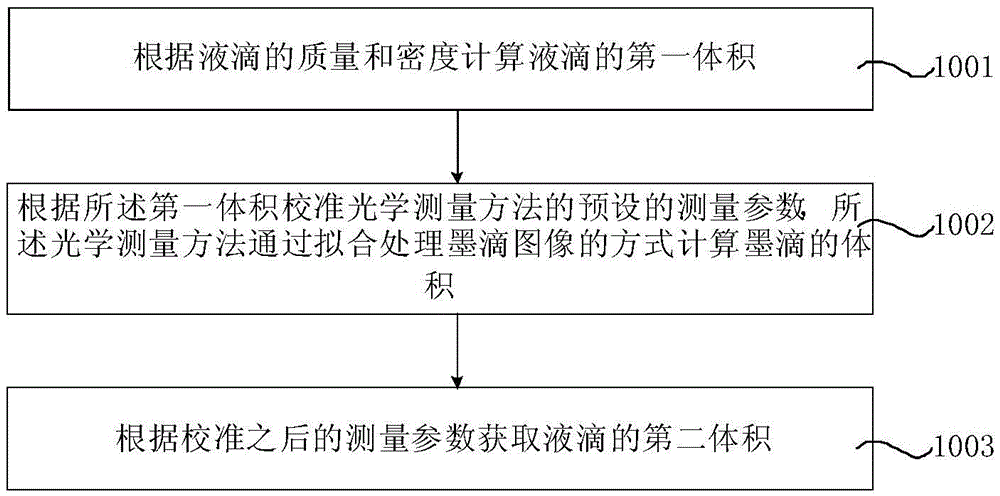

[0070] image 3 It is a flow chart of a method for calibrating the volume of an ink drop provided by Embodiment 1 of the present invention. like image 3 As shown, the calibration method of the ink droplet volume includes:

[0071] Step 1001, calculate the first volume of the ink drop according to the mass and density of the ink drop.

[0072] In this embodiment, before the step of calculating the first volume of the ink drop according to the mass and density of the ink drop includes: obtaining the total mass of the multiple ink drops; obtaining the total number of the multiple ink drops; and obtaining the density of the ink drop. Optionally, the step of calculating the first volume of ink droplets according to the mass and density of ink droplets includes: calculating the total volume of multiple ink droplets according to the total mass and density of multiple ink droplets; The volume and total count calculate the first volume of the ink drop. Specifically, the total mass...

Embodiment 2

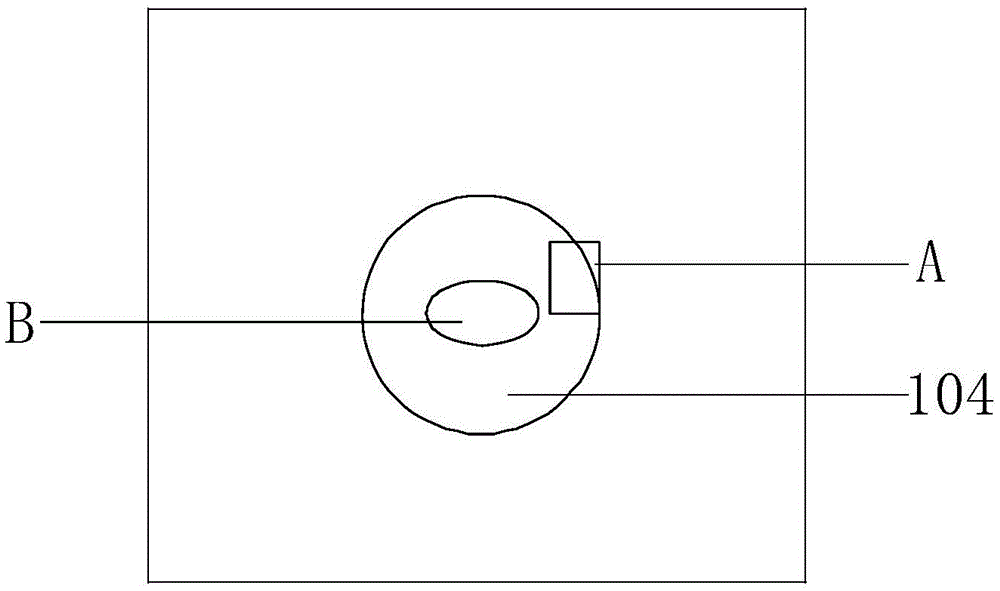

[0079] Figure 4 It is a schematic structural diagram of an ink droplet volume calibration system provided by Embodiment 2 of the present invention. like Figure 4 As shown, the ink drop volume calibration system includes a first calculation unit 101, a first calibration unit 102 and a first acquisition unit 103, and the first calculation unit 101 is used to calculate the first ink drop volume according to the mass and density of the ink drop. Volume; the first calibration unit 102 is used to calibrate the preset measurement parameters of the optical measurement method according to the first volume, and the optical measurement method calculates the volume of the ink drop by fitting and processing the ink drop image; the first acquisition unit Step 103 is used to obtain the second volume of the ink drop according to the measured parameter after calibration. The technical solution provided in this embodiment combines the weighing measurement method with the optical measurement...

Embodiment 3

[0086] This embodiment provides a printing device, including the ink droplet volume calibration system provided in Embodiment 2. For details, please refer to the description of Embodiment 2, which will not be repeated here.

[0087]In the printing device provided in this embodiment, the ink drop volume calibration system calculates the first volume of the ink drop according to the mass and density of the ink drop, and calibrates the preset measurement parameters of the optical measurement method according to the first volume. The optical measurement method calculates the volume of the ink drop by fitting and processing the image of the ink drop, and obtains the second volume of the ink drop according to the measured parameters after calibration. The technical solution provided in this embodiment combines the weighing measurement method with the optical measurement method, and calibrates the measurement parameters of the optical measurement method according to the results of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com