Ultrasonic air dissolving system

An ultrasonic and dissolved air technology, applied in the direction of flotation water/sewage treatment, mechanical oscillation water/sewage treatment, grease/oily substance/floating matter removal device, etc., can solve the problem of ensuring full contact between gas and liquid, and mixing of water and gas Problems such as poor fluidity, low dissolved gas and water-soluble gas, to achieve the effect of promoting gas-liquid contact, ensuring sufficient contact, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

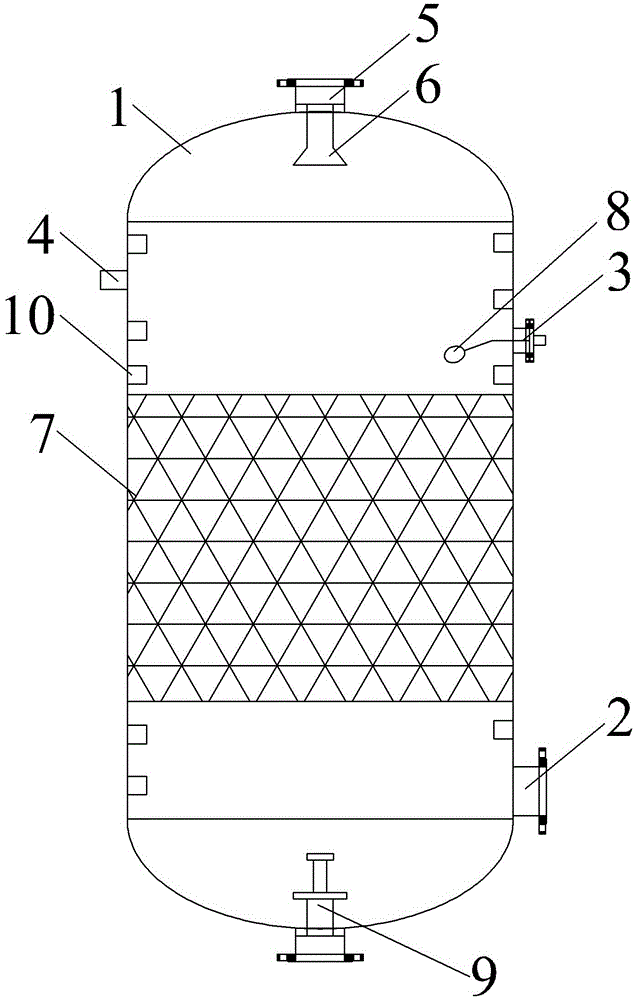

[0008] Such as figure 1 As shown, the present invention includes an air-dissolving tank 1. The main body of the dissolving air tank 1 is a vertical column structure. A water outlet 2 is provided on the lower side wall of one end of the dissolving air tank 1. The dissolving air tank located on the same side as the water outlet 2 1. A liquid level float switch 3 is provided on the upper end wall. An air inlet 4 is provided on the upper side wall of the other end of the dissolved air tank 1. A water inlet 5 is provided at the top of the dissolved air tank 1. A water inlet 5 is provided below the water inlet 5. There is a nozzle 6 with the opening facing down, and it is located in the gas dissolving tank 1, which can be directly sprayed to promote the gas-liquid contact. Quality and efficiency, the float 8 of the liquid level float switch 3 is located above the inner filler 7 of the dissolved gas tank 1, and the inner bottom of the dissolved gas tank 1 is provided with an ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com