Composite slowly-recoverable soft polyurethane foam and preparation method thereof

A soft foam and slow rebound technology, applied in the field of polyurethane soft foam, can solve the problems of low dependence, slow rebound, strong foam temperature dependence, etc., and achieve the effect of small dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

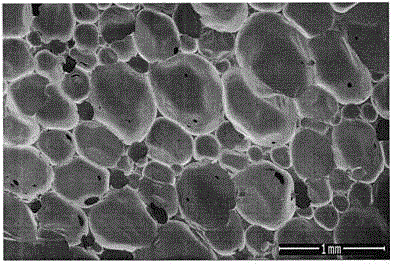

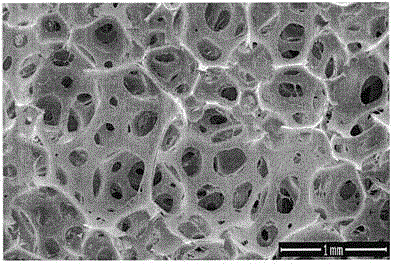

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment. The raw materials involved are calculated in parts by weight unless otherwise specified.

[0031] The slow resilience of foam is characterized by "rebound rate" and "recovery time", the lower the rate of resilience, the longer the recovery time. Generally, the rebound rate of the slow-rebound foam is less than 20%, and the recovery time is 3-15s, preferably the rebound rate is less than 5%, and the recovery time is 7-15s. When the rebound rate is too high and the recovery time is too low, the slow rebound characteristics of the foam are not obvious.

[0032] The so-called "air bag feeling" in the present invention refers to the "flatulence" feeling that the foam has a very small opening. .

[0033] Polyether 1 is a 3-functionality, glycerol initiated, all propylene oxide polyether polyol with an equivalent weight of 236 and a hydroxyl number of 238 mgKOH / g.

[0034] Polyether 2 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com